/VISC/LPRONY

Block Format Keyword This model describes an isotropic visco-elastic Maxwell model that can be used to add visco-elasticity to solid element with total strain formulation (Ismstr=10 or 12).

The visco-elasticity is input using a Prony series.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /VISC/LPRONY/mat_ID/unit_ID | |||||||||

| M | Form | flag_visc | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier which refers to

the viscosity card. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit identifier. (Integer, maximum 10 digits) |

|

| M | Maxwell model order (number of

Prony coefficients). Maximum order is 100. Default = 1 (Integer) |

|

| Form | Initial visco-elastic modulus

formulation used.

(Integer) |

|

| flag_visc | Viscous formulation flag.

(Integer) |

|

| Shear relaxation modulus for

th term (

=1,

M). (Real) |

||

| Relaxation time for

th term (

=1,

M). (Real) |

Comments

- This viscous model is available only for total strain formulation with Ismstr=10 or 12 in the solid property).

- Form=1 is available only for material law /MAT/LAW42 (OGDEN), /MAT/LAW62 (VISC_HYP) and /MAT/LAW69.

- The viscosity model is ignored in case it is applied on a non-compatible material or strain formulation.

- Coefficients (

,

) are used to describe rate effects through

the Maxwell model.

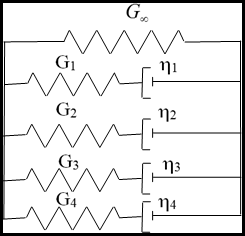

Figure 1.

The initial shear modulus given by the formula below, it corresponds to the shear modulus of material law.

and

The stiffness ratio is defined using:

Where, .

- The viscosity effect is taken into account by using a Prony series.

The Kirchhoff viscous stress is computed using:

with .