/SLIPRING/SHELL

Block Format Keyword Define a 2D slipring for seatbelt elements defined with /MAT/LAW119 and /PROP/TYPE9.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /SLIPRING/SHELL/slipring_ID/unit_ID | |||||||||

| slipring_title | |||||||||

| El_Gr1 | El_Gr2 | Gr_Nod | Sens_ID | Fl_flag | Ed_factor | ||||

| fct_ID1 | fct_ID2 | Fric_d | Xscale1 | Yscale2 | Xscale2 | ||||

| fct_ID3 | fct_ID4 | Fric_s | Xscale3 | Yscale4 | Xscale4 | ||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| slipring_ID | Slipring identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit identifier. (Integer, maximum 10 digits) |

|

| slipring_title | Slipring title. (Character, maximum 100 characters) |

|

| El_Gr1 | ID of first group (or set) of

elements in slipring. 2

3 (Integer, maximum 10 digits) |

|

| El_Gr2 | ID of second group (or set) of

elements in slipring. 2

3

(Integer, maximum 10 digits) |

|

| Gr_Nod | Group of anchorage nodes. 4

(Integer, maximum 10 digits) |

|

| Sens_ID | Sensor identifier used for slipring locking.

(Integer) |

|

| Fl_flag | Sliding direction control flag.

(Integer) |

|

| Ed_factor | Exponential decay factor for

Coulomb friction. (Real) |

|

| fct_ID1 | Dynamic Coulomb friction

coefficient as a function of time

identifier. (Integer) |

|

| fct_ID2 | Dynamic Coulomb friction

coefficient as a function of normal force

identifier, (Integer) |

|

| Fric_d |

(Real) |

|

| Xscale1 | Abscissa scaling factor for

function fct_ID1. (Real) |

|

| Xscale2 | Abscissa scaling factor for

function fct_ID2. (Real) |

|

| Yscale2 | Ordinate scaling factor for

function fct_ID2. (Real) |

|

| fct_ID3 | Static Coulomb friction coefficient

as a function of time identifier. (Integer) |

|

| fct_ID4 | Static Coulomb friction coefficient

as a function of normal force

identifier. (Integer) |

|

| Fric_s |

(Real) |

|

| Xscale3 | Abscissa scaling factor for

function fct_ID3. (Real) |

|

| Yscale4 | Ordinate scaling factor for

function fct_ID4. (Real) |

|

| Xscale4 | Abscissa scaling factor for

function fct_ID4. (Real) |

Comments

- The /SLIPRING/SHELL option is an extension to seatbelt shell elements of the /SLIPRING/SPRING. It can be seen as sequence of /SLIPRING/SPRING. The parameters are almost the same; therefore, refer to /SLIPRING/SPRING for a detailed explanation concerning parameters, slipring updates during the run, locking and friction.

- The /SLIPRING/SHELL can only be connected to seatbelt shell elements, shells using a seatbelt material (/MAT/LAW119 (SH_SEATBELT)).

- The

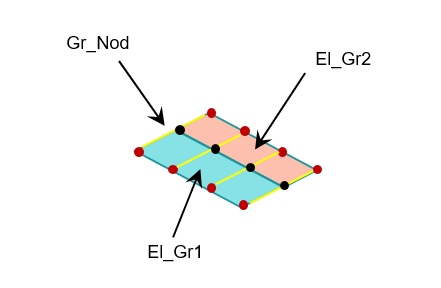

/SLIPRING/SHELL is defined by the 2 groups of shell

elements initially connected to the slipring, El_Gr1,

El_Gr2 and a group of nodes Gr_Nod

used to define the position of the slipring. The common node between the

elements of El_Gr1 and El_Gr2 must be

at the same position as Gr_Nod.

Figure 1.

- The slipring must be represented by a line; therefore, the nodes of Gr_Nod must be aligned and can not be nodes of the seatbelt shell elements. All the nodes of Gr_Nod must belong to a single rigid body or boundary condition (all DOF fixed).

- At any time, the common nodes of the shell seatbelt elements are kinematically attached to the corresponding anchorage nodes. No other kinematic condition can be applied to theses nodes.

- Shell elements that are connected to the slipring are deactivated and are reactivated when they are outside of the slipring. The activation/deactivation of shell elements is progressive, and a scaling factor computed from the distance between the shell element and the slipring is applied on the stresses.

- 2D seatbelt uses /PROP/TYPE9 (SH_ORTH) with IP = 24 and Iskew > 0.