/SLIPRING/SPRING

Block Format Keyword Define 1D slipring for seatbelt elements defined with /MAT/LAW114 and /PROP/TYPE23.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /SLIPRING/SPRING/slipring_ID/unit_ID | |||||||||

| slipring_title | |||||||||

| El_ID1 | El_ID2 | node_ID1 | node_ID2 | sens_ID | Fl_flag | A | Ed_factor | ||

| fct_ID1 | fct_ID2 | Fric_d | Xscale1 | Yscale2 | Xscale2 | ||||

| fct_ID3 | fct_ID4 | Fric_s | Xscale3 | Yscale4 | Xscale4 | ||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| slipring_ID | Slipring identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

| slipring_title | Slipring title title. (Character, maximum 100 characters) |

|

| El_ID1 | ID of first element in

slipring. (Integer, maximum 10 digits) |

|

| El_ID2 | ID of second element in

slipring. (Integer, maximum 10 digits) |

|

| node_ID1 | ID of anchorage node.

(Integer, maximum 10 digits) |

|

| node_ID2 | Optional ID of node for the

orientation of the slipring. (Integer, maximum 10 digits) |

|

| sens_ID | Sensor identifier used for slipring

locking.

(Integer) |

|

| Fl_flag | Sliding direction control flag

(Integer) |

|

| A | Coulomb friction scale

factor. (Real) |

|

| Ed_factor | Exponential decay factor for

Coulomb friction. (Real) |

|

| fct_ID1 | Function identifier defining

dynamic Coulomb friction coefficient as a function of

time. (Integer) |

|

| fct_ID2 | Function identifier defining

dynamic Coulomb friction coefficient as a function of normal

force. (Integer) |

|

| Fric_d | Dynamic Coulomb friction

coefficient. If fct_ID1 = 0: constant value (Default = 0). If fct_ID1 > 0: ordinate scaling factor for function fct_ID1 (Default = 1). (Real) |

|

| Xscale1 | Abcissa scaling factor for function

fct_ID1. Default = 1 (Real) |

|

| Yscale2 | Ordinate scaling factor for

function fct_ID2. Default = 1 (Real) |

|

| Xscale2 | Abcissa scaling factor for function

fct_ID2. Default = 1 (Real) |

|

| fct_ID3 | Function identifier defining static

Coulomb friction coefficient as a function of

time. (Integer) |

|

| fct_ID4 | Function identifier defining static

Coulomb friction coefficient as a function of normal

force. (Integer) |

|

| Fric_s | Static Coulomb friction

coefficient. If fct_ID3= 0: constant value (Default = 0). If fct_ID3> 0: ordinate scaling factor for function fct_ID2 (Default = 1). (Real) |

|

| Xscale3 | Abcissa scaling factor for function

fct_ID3. Default = 1 (Real) |

|

| Yscale4 | Ordinate scaling factor for

function fct_ID4. Default = 1 (Real) |

|

| Xscale4 | Abcissa scaling factor for function

fct_ID4. Default = 1 (Real) |

Comments

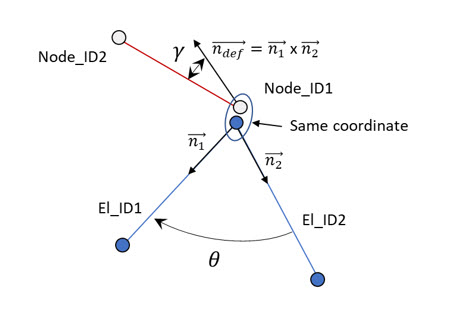

- The slipring is defined by the 2 spring seatbelt elements initially connected to the slipring, El_ID1, El_ID2 and the node node_ID1 are used to define the position of the slipring. The common node between the 2 elements El_ID1 and EL_ID2 must be at the same coordinates as node_ID1.

- node_ID1 and node_ID2 must not be nodes of the seatbelt spring component.

- By default, the

rotation axis of the slipring is defined by

, the normal direction to the plane defined

by the two connected elements. Additionally, the rotation axis of the slipring can be defined by the direction of node_ID1 and node_ID2. the angle between the direction of node_ID1 and node_ID2 and is used to compute the friction.

Figure 1. - The Coulomb friction

coefficient is computed with:

(1) Where,- Static friction coefficient

- Dynamic friction coefficient

- Relative slip velocity

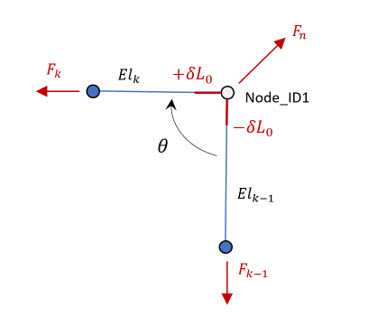

They are respectively computed with:(2) (3) - When the slipring is

unlocked, sliding is activated if the difference of force after flow (marked

with *) is lower than the difference of force obtained without flow, and

material flow

is computed accordingly:

with

Figure 2. - The common node of the 2 strands of the slipring is kinematically attached to the anchorage node of the slipring node_ID1. No other kinematic condition can be applied to any node of a seatbelt element which can enter the slipring.

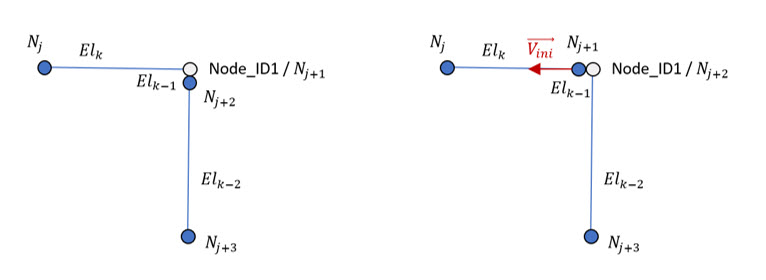

- When the length of one

strand reaches zero, the slipring is updated. This strand reappears on the

other side of the slipring and the previously connected strand on that side

leaves the slipring. At the same time, a new spring enters the slipring

replacing the one that has moved. The kinematic condition with the anchorage

node is also switched to the new common node of the strands. The previous

common node is released with an initial velocity computed from the material

flow and direction of the released element, such that the two directions of

the slipring

and

and the angle

are not modified by the update.

(4)

Figure 3. - To ensure element and

time step stability, maximum stiffness value is computed from

defined in seatbelt

material (/MAT/LAW114) and spring element reference

length

.

(5) - When a spring element is in the slipring, viscosity is deactivated.