/MAT/LAW127 (ENHANCED_COMPOSITE)

Block Format Keyword The model may be used to model composite materials with unidirectional layers. This model is implemented only for shell, thick shell and solid elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW127/mat_ID/unit_ID or /MAT/ENHANCED_COMPOSITE/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E11 | E22 | E33 | |||||||

| G12 | G13 | G23 | |||||||

| SLIMT1 | Fct_IDT1 | FscaleT1 | |||||||

| SLIMT2 | Fct_IDT2 | FscaleT2 | |||||||

| SLIMS | Fct_IDS | FscaleS | |||||||

| SLIMC1 | Fct_IDC1 | FscaleC1 | |||||||

| SLIMC2 | Fct_IDC2 | FscaleC2 | |||||||

| Fcut | |||||||||

| 2WAY | TI | ||||||||

| DFAILT | DFAILC | DFAILS | DFAILM | RATIO | |||||

| NCYRED | FBRT | YCFAC | |||||||

| EFS | EPSF | EPSR | TSMD | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E11 | Young’s modulus in fiber,

longitudinal direction 1. (Real) |

|

| E22 | Young’s modulus in matrix,

transverse direction 2. (Real) |

|

| E33 | Young’s modulus in matrix, normal

direction 3. (Real) |

|

| G12 | Shear modulus

12. (Real) |

|

| G13 | Shear modulus

13. (Real) |

|

| G23 | Shear modulus

23. (Real) |

|

| Poisson’s ratio

21. (Real) |

||

| Poisson’s ratio

31. (Real) |

||

| Poisson’s ratio

32. (Real) |

||

| Maximum tensile stress in direction

1. Ignore if Fct_IDT1 is

defined. Default = 1E+20 (Real) |

||

| SLIMT1 | Factor to determine the minimum

stress limit after stress maximum

is reached. 2 Default = 1.0 (Real) |

|

| Fct_IDT1 | Load curve identifier defining the

tensile stress in direction 1

as a function of strain rate. (Integer) |

|

| FscaleT1 | Stress scale factor for the

function Fct_IDT1. Default = 1.0 (Real) |

|

| Maximum tensile stress in direction

2. Ignore if Fct_IDT2 is

defined. Default = 1E+20 (Real) |

||

| SLIMT2 | Factor to determine the minimum

stress limit after stress maximum

. 2 Default = 1.0 (Real) |

|

| Fct_IDT2 | Load curve identifier defining the

tensile stress in direction 1

as a function of strain rate. (Integer) |

|

| FscaleT2 | Stress scale factor for the

function Fct_IDT2. Default = 1.0 (Real) |

|

| Maximum shear stress in plane 12.

Ignore if Fct_IDS is

defined. Default = 1E+20 (Real) |

||

| SLIMS | Factor to determine the minimum

stress limit after stress maximum

. 2 Default = 1.0 (Real) |

|

| Fct_IDS | Load curve ID defining the shear

stress in plane 12.

as a function of strain rate. (Integer) |

|

| FscaleS | Stress scale factor for the

function Fct_IDS. Default = 1.0 (Real) |

|

| Maximum compression stress in

direction 1. Ignore if Fct_IDC1 is

defined. Default = 1E+20 (Real) |

||

| SLIMC1 | Factor to determine the minimum

stress limit after stress maximum

is reached. 2 Default = 1.0 (Real) |

|

| Fct_IDC1 | Load curve identifier defining the

compression stress in direction 1

as a function of strain rate. (Integer) |

|

| FscaleC1 | Stress scale factor for the

function Fct_IDC1. Default = 1.0 (Real) |

|

| Maximum compression stress in

direction 2. Ignore if Fct_IDC2 is

defined. Default = 1E+20 (Real) |

||

| SLIMC2 | Factor to determine the minimum

stress limit after stress maximum

is reached. 2 Default = 1.0 (Real) |

|

| Fct_IDC2 | Load curve identifier defining the

compression stress in direction 1

as a function of strain rate. (Integer) |

|

| FscaleC2 | Stress scale factor for the

function Fct_IDC2. Default = 1.0 (Real) |

|

| Fcut | Equivalent strain rate cutoff

frequency. Default = 5000 Hz (Real) |

|

| Shear stress parameter for the

nonlinear term. 3 Default = 0.0 (Real) |

||

| Weighing factor for shear term in

tensile fiber mode. 3 0.0 ≤ ≤ 1.0 Default = 0.0 (Real) |

||

| 2WAY | Flag to turn on 2-way fiber action.

This option is available only for solid and thick shells.

(Integer) |

|

| TI | Flag to turn on transversal

isotropic behavior for material solid elements. 7

(Integer) |

|

| DFAILT | Maximum strain for fiber tension.

5 If 2WAY =1, then DFAILT is the fiber tensile failure strain in the first and second directions. Default = 1E+10 (Real) |

|

| DFAILC | Maximum strain for fiber

compression (active only if DFAILT >

0). The input value should be negative.

5 Default = -1E+10 (Real) |

|

| DFAILS | Maximum tensorial shear strain

(active only if DFAILT > 0).

5 Default = 1E+10 (Real) |

|

| DFAILM | Maximum strain for matrix straining

in tension or compression (active only if

DFAILT > 0). 5 Default = 1E+10 (Real) |

|

| RATIO | Ratio parameter control to delete

shell elements. Defines a ratio of failed plies in

thickness. Default = 1.0 (Real) |

|

| NCYRED | Number of cycles for stress

reduction from maximum to minimum. Default = 1 (Integer) |

|

| FBRT | Softening factor for fiber tensile stress:

Default = 1.0 (Real) |

|

| YCFAC | Reduction factor for compressive

fiber stress after matrix compressive failure. The compressive

stress in the fiber direction

is reduced by

YCFAC after compressive matrix

failure. Default = 2.0 (Real) |

|

| EFS | Maximum effective strain for

element layer failure. 5 Default = 1E+10 (Real) |

|

| EPSF | Damage initiation transverse shear

strain. 6 Default = 1E+10 (Real) |

|

| EPSR | Final rupture transverse shear

strain. 6 Default = 2E+10 (Real) |

|

| TSMD | Transverse shear maximum damage.

6 Default = 0.90 (Real) |

Example (Composite)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

Unit for material

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW127/1

Composite

# Init. dens.

1.5E-09

# E11 E22 E33

15000.0 15000.0 15000.0

# G12 G13 G23

5000.0 1000.0 1000.0

# Nu21 Nu31 Nu32

0.1 0.1 0.1

# SIG_T1 SLIM_T1 FCT_ID_T1 FSCALE_T1

400.0 0.25 0 0.0

# SIG_T2 SLIM_T2 FCT_ID_T2 FSCALE_T2

400.0 0.25 0 0.0

# SIG_S SLIM_S FCT_ID_S FSCALE_S

50.0 1.0 0 0.0

# SIG_C1 SLIM_C1 FCT_ID_C1 FSCALE_C1

200.0 0.5 0 0.0

# SIG_C2 SLIM_C2 FCT_ID_C2 FSCALE_C2

200.0 0.5 0 0.0

# FCUT

0.0

# ALPH BETA 2WAY TI

0.0 0.0 0 0

# DFAILT DFAILC DFAILS DFAILM RATIO

0.05 -0.2 0.2 0.3 0.0

# NCYRED FBRT YCFAC

10 0.0 0.0

# EFS EPSF EPSR TSMD

0.2 0.5 0.8 1.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This material model presents linear elastic behavior until failure.

Pseudo-plastic behavior is implemented as post-failure behavior until

reaching a strain criterion controlling the ultimate material failure:

- Under 2D stress conditions, for shells, the stress/strain

relationship in the orthotropic frame is given by:Where,

- Out of plane shear coefficient scale factor

- The 3D stress/strain relationship in the orthotropic frame is given

by:

Where,

- Under 2D stress conditions, for shells, the stress/strain

relationship in the orthotropic frame is given by:

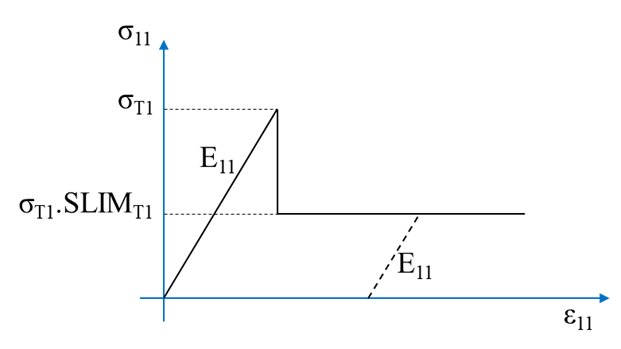

- Pseudo-Plastic behavior is considered at the post failure behavior

for each direction:

Figure 1. Behavior in direction 1

- The

Chang-Chang criteria are given as:

- Tensile Fiber mode:

If , shell element ply is removed if DFAILT =0 or solid element is deleted.

- Compressive Fiber mode:

If , is set to minimum stress limit.

- Tensile Matrix mode:

If , is set to minimum stress limit.

- Compressive Matrix mode:

If , is set to minimum stress limit.

- The original criterion of Hashin in the tensile fiber mode is set with = 1.

- For = 0, you get the maximum stress criterion which is found to compare better to experiments.

- Tensile Fiber mode:

- If the

2WAY fiber flag is set, then the failure criteria for

tensile and compressive fiber failure in the orthotropic 1 direction are

unchanged. For orthotropic direction 2, the same failure criteria as for the

1-direction fibers are used:

- Tensile fiber mode in the orthotropic direction 2:

If , shell element ply is removed if DFAILT =0 or solid element is deleted.

- Compressive fiber mode in the orthotropic direction

2:

If , is set to minimum stress limit.

- Matrix fails only in shear:

If , is set to minimum stress limit.

- Tensile fiber mode in the orthotropic direction 2:

- Integration point failure can occur in three different ways:

- If DFAILT is zero, failure occurs if the Chang-Chang failure criterion is satisfied in the tensile fiber mode.

- If DFAILT is greater than zero, failure occurs

if:

- The fiber strain is greater than DFAILT or less than DFAILC

- If the absolute value of matrix strain is greater than DFAILM

- If the absolute value of tensorial shear strain is greater than DFAILS

- If EFS is greater than zero, failure occurs if the effective strain is greater than EFS.

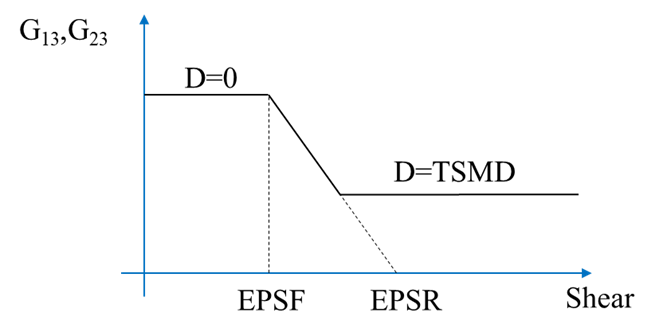

- Transverse shear strain damage model.

In an optional damage model for transverse shear strain, out-of-plane stiffness (G13 and G23) can linearly decrease to model interlaminar shear failure. Damage starts when effective transverse shear strain reaches EPSF. Final rupture occurs when effective transverse shear strain reaches EPSR.

A maximum damage of TSMD (0.0 < TSMD < 0.99) cannot be exceeded.Figure 2. Linear damage for transverse shear behavior

- The flag

TI applies only to transversal isotropic behavior for

material solid elements. the stress/strain relationship is given using the

3D stress/Strain relationship, under the following

conditions:

- Damage

mode value can be display with the output

/H3D/ELEM/DAMG/ID=<mat_ID>/MODE=ALL/… with the

following output:

- Tensile fiber damage

- Compressive tensile damage

- Tension transverse matrix damage

- Compressive transverse matrix damage

- Shear matrix damage