/MAT/LAW122 (MODIFIED_LADEVEZE)

Block Format Keyword A simple unidirectional composite ply model, accounting for orthotropic elasticity and plasticity. Fiber and matrix damage are considered, including strain rate effect.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW122/mat_ID/unit_ID or /MAT/MODIFIED_LADEVEZE/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| ISH | ITR | IRES | |||||||

| M | A | ||||||||

| IBUCK | |||||||||

| IFUNCD1 | b | ||||||||

| DMAX | |||||||||

| IFUNCD2 | |||||||||

| IFUNCD2C | |||||||||

| LTYPE11 | LTYPE12 | LTYPER0 | |||||||

| FCUT | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| Young’s modulus in fiber direction

1 for tension. (Real) |

||

| Young’s modulus in matrix direction

2. (Real) |

||

| Young’s modulus in matrix direction

3. (Real) |

||

| Shear modulus in the plane

12. (Real) |

||

| Shear modulus in the plane

23. (Real) |

||

| Shear modulus in the plane

13. (Real) |

||

| Poisson’s ratio in the plane

12. (Real) |

||

| Poisson’s ratio in the plane

23. (Real) |

||

| Poisson’s ratio in the plane

31. (Real) |

||

| Young’s modulus in fiber direction

1 for compression. (Real) |

||

| Compressive factor of the modulus

correction. (Real) |

||

| ISH | Shear matrix damage flag.

(Integer) |

|

| ITR | Transverse matrix damage flag.

(Integer) |

|

| IRES | Return mapping algorithm flag.

(Integer) |

|

| Initial yield stress. Default = 1020 (Real) |

||

| Hardening

modulus. (Real) |

||

| M | Hardening

exponent. (Real) |

|

| A | Shear and transverse plasticity

coupling factor. (Real) |

|

| Tensile initial damage strain in

fiber direction 1. Default = 1020 (Real) |

||

| Tensile ultimate damage strain in

fiber direction 1. Default = 2*1020 (Real) |

||

| Tensile ultimate damage in fiber

direction 1. (Real) |

||

| Compression initial damage strain

in fiber direction 1. Default = 1020 (Real) |

||

| Compression ultimate damage strain

in fiber direction 1. Default = 2*1020 (Real) |

||

| Compression ultimate damage in

fiber direction 1. (Real) |

||

| IBUCK | Buckling damage matrix on fiber in

compression flag.

(Integer) |

|

| IFUNCD1 | Matrix shear tabulated damage

function identifier. (Integer) |

|

| Damage saturation for matrix shear

exponential damage. (Real) |

||

| Initial matrix shear damage

threshold / Abscissa scale factor for tabulated

damage. Default = 1020 or 1.0 (Real) |

||

| Critical matrix shear damage

limit. (Real) |

||

| b | Shear/transverse matrix damage

coupling factor. Default = (Real) |

|

| DMAX | Damage maximum allowed

value. (Real) |

|

| Elementary shear damage

value. Default = 1020 (Real) |

||

| Brittle damage limit for

fiber-matrix interface. Default = 1020 (Real) |

||

| IFUNCD2 | Tension transverse matrix tabulated

damage function identifier. (Integer) |

|

| Damage saturation for transverse

matrix exponential damage in tension. (Real) |

||

| Initial transverse matrix damage

threshold in tension / Abscissa scale factor for tabulated

damage. Default = 1020 or 1.0 (Real) |

||

| Critical transverse matrix damage

limit in tension. (Real) |

||

| IFUNCDC2 | Compression transverse matrix

tabulated damage (shells only) function

identifier. (Integer) |

|

| Damage saturation for compression

transverse matrix exponential damage (shells

only). (Real) |

||

| Initial transverse damage threshold

in compression / Abscissa scale factor for tabulated damage

(shells only). (Real) |

||

| Critical transverse damage limit in

compression (shells only). (Real) |

||

| Reference strain rate for fiber

direction 1. Default = 1.0 (Real) |

||

| First parameter for Young’s modulus

strain rate dependency in fiber direction

1. (Real) |

||

| Second parameter for Young’s

modulus strain rate dependency in fiber direction

1. (Real) |

||

| First parameter for rupture strain

rate dependency in fiber direction 1. (Real) |

||

| Second parameter for rupture strain

rate dependency in fiber direction 1. (Real) |

||

| Reference strain rate for shear and

transverse directions. Default = 1.0 (Real) |

||

| First parameter for Young’s modulus

strain rate dependency in matrix transverse direction

2. (Real) |

||

| Second parameter for Young’s

modulus strain rate dependency in matrix transverse direction

2. (Real) |

||

| First parameter for shear modulus

strain rate dependency in plane 12. (Real) |

||

| Second parameter for shear modulus

strain rate dependency in plane 12. (Real) |

||

| Reference strain rate for initial

yield stress. Default = 1.0 (Real) |

||

| First parameter for initial yield

stress strain rate dependency. (Real) |

||

| Second parameter for initial yield

stress strain rate dependency. (Real) |

||

| LTYPE11 | Strain rate dependency law type for

fiber direction 1.

(Integer) |

|

| LTYPE12 | Strain rate dependency law type for

shear and transverse directions.

(Integer) |

|

| LTYPER0 | Strain rate dependency law type for

initial yield stress.

(Integer) |

|

| FCUT | Equivalent strain rate cutoff

frequency. Default = 5 kHz (Real) |

Example (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

Test unit

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW122/1/1

Steel

# Init. dens.

1.8E-9

# E1 E2 E3 G12 G23

135000 1000 1000 4000 4000

# G31 NU12 NU23 NU31

4000 0.33 0.1 0.33

# E1C GAMMA ISH ITR IRES

138000 1.7E-4 0 0 2

# SIGY0 BETA M A

20 0.7986 0.5166 0.33

# EPS_FTI EPS_FTU DFTU

0.002 0.0025 1.0

# EPS_FCI EPS_FCU DCFU IBUCK

0.0104 0.0105 1.0 1

# IFUNCD1 DSAT1 Y0 YC B

0.158 0.05

# DMAX YR YSP

0.95 1.5811 1.0e20

# IFUNCD2 DSAT2 Y0P YCP

0.158 0.05

# IFUNCD2C DSAT2C Y0PC YCPC

0.158 0.05

# EPSD11 D11 N11 D11U N11U

# EPSD12 D22 N22 D12 N12

# EPSDR0 DR0 NR0 LTYPE11 LTYPE12 LTYPER0

# FCUT

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

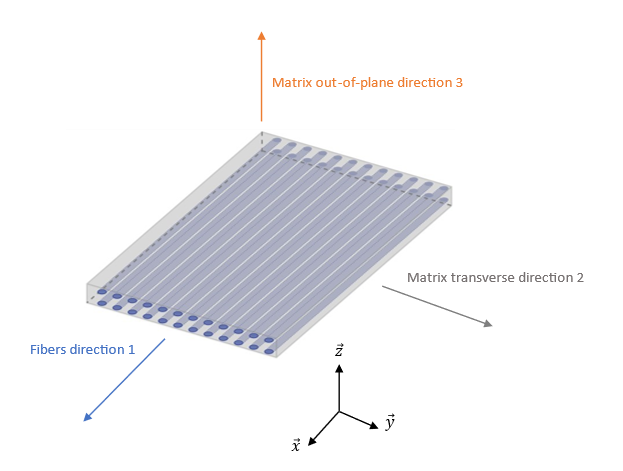

- The modified Ladeveze model considers a unidirectional composite ply

where fibers are to be oriented in the direction 1, and the matrix in the

transverse directions 2 and 3. This material orientation will then be

identified as

,

,

(Figure 1). The “out of plane” transverse

direction will then correspond to

-axis for shell and thickshell elements.

Figure 1. Unidirectional ply and its material orientation considered by /MAT/LAW122 - The elastic behavior is assumed to be orthotropic. Under 2D plane

stress conditions, for shells, the stress/strain relationship is given by:

with

Where, .

This nonlinear evolution of compression Young’s modulus in fiber direction is used to represent the effect of fiber micro buckling and misalignment. is the shear factor used for shells only and defined in the property.

For 3D stress conditions (solid elements and thickshells), the inverse of compliance matrix is used to link the stresses with the strains:(1) The same non-linearity of fiber direction Young’s modulus in compression is used.

- In fiber directions 1 (or

-axis), the behavior remains purely elastic

until damage occurs (detailed below). However, the plastic behavior of the

matrix is considered under transverse and shear loadings. The elastic limit

is introduced through a yield function that differs from solids to shells:

- For Shells:

(2) - For Solids:

(3)

Where, is a coupling factor whose value can be set to 0.33 for an isotropic resin. In this equation, the yield function is defined as:(4) This describes an isotropic hardening following a power law. The hardening modulus is numerically bounded by the value to avoid stability issues.

- For Shells:

- Like elasticity or plasticity, the damage behavior is assumed to be

orthotropic. Three damage variables are then defined:

,

and

which respectively describes the fiber

rupture, the shear matrix damage, and the transverse matrix damage.

- Fiber damage

affects the behavior along the fiber

direction 1. Under tension loading condition, fiber damage evolves

following the equations.

(5) Where, is the strain at the onset of damage, is the ultimate strain, is the ultimate damage value and is the equivalent fiber strain defined by:- For Shells:

(6) - For Solids:

(7)

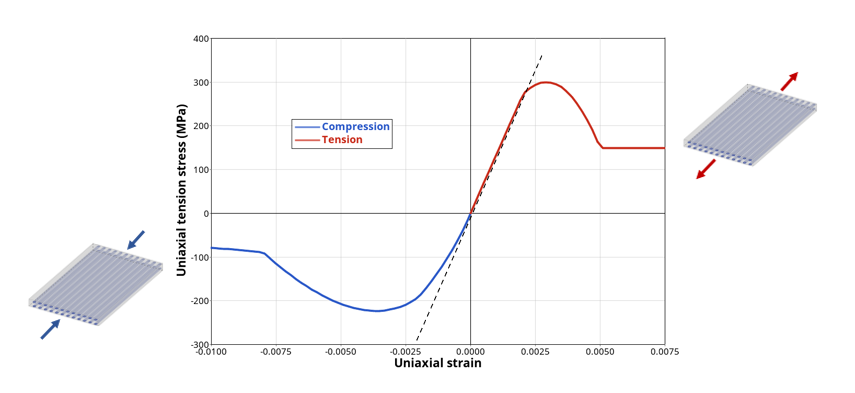

The compression damage on fiber due to matrix buckling can be activated with the IBUCK flag and is described with a similar equation:(8) This fiber damage then affects the stress computation as:(9) Figure 2 shows the expected behavior in tension/compression along the fiber direction. The dashed line allows to highlight the nonlinear Young’s modulus in compression.

Figure 2. Tension/compression test in fiber direction showing fiber damage effect on stressNote: Along fiber direction, the behavior is purely elastic and damaging. - For Shells:

- Shear matrix damage

is introduced to represent the

debonding between matrix and fibers. Its evolution is influenced by

the energy release rate often used in Lemaitre-type damage model.

Two elastic energy rates are considered in this model.

- For Shells:

(10) Where, are the Macauley’s brackets that only considers the positive values of . However, if compression damage described below is considered (for shells only), these brackets becomes simple parenthesis.

- For Solids:

(11) This then leads to the following computation:(12) Where, is a coupling factor.

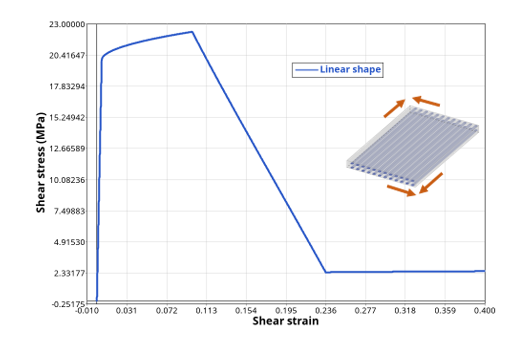

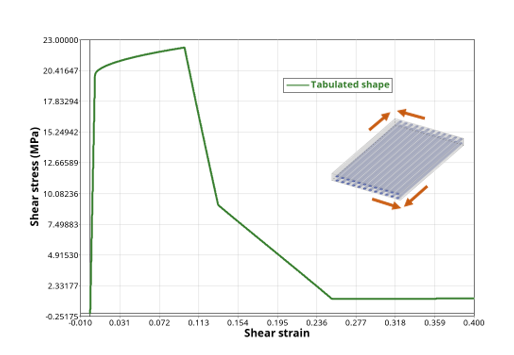

Depending on the value of the flag ISH, the shear matrix damage can evolve with different shapes.- ISH = 1: linear

shape (Figure 3)

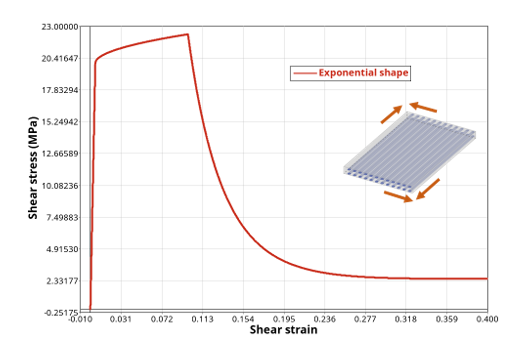

Figure 3. Shear test showing shear matrix damage effect with a linear shape - ISH = 2: exponential

shape (Figure 4)

Figure 4. Shear test showing shear matrix damage effect with an exponential shape - ISH = 3: tabulated

shape (Figure 5)Where, is the function identified by IFUNCD1.

Figure 5. Shear test showing shear matrix damage effect with a tabulated shape

The shear matrix damage then affects the stresses computation as:- For Shells:

(13) - For Solids:

(14)

- For Shells:

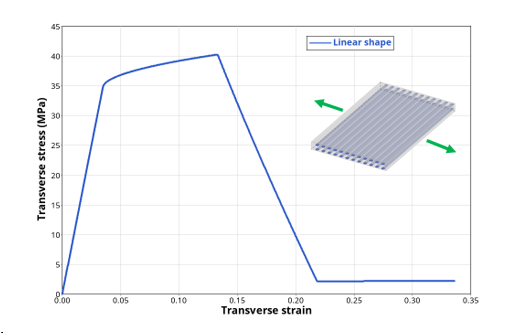

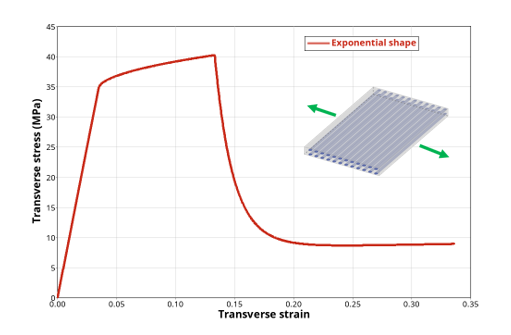

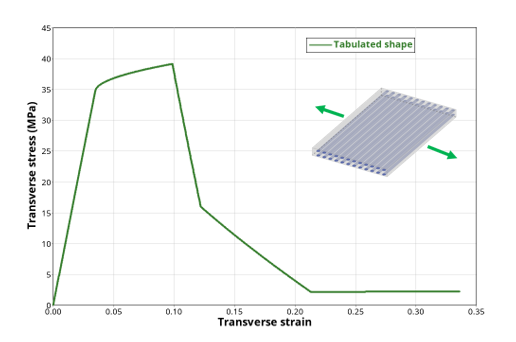

- Transverse matrix damage

allows to represent the

microcracking of the matrix. Its evolution is very similar to shear

matrix damage, except from the fact that a different elastic energy

release rate is used:

(15) Then, like shear matrix damage, three different evolution shapes are available depending on the ITR flag value.- ITR = 1: linear

shape (Figure 6)

Figure 6. Tensile test in transverse direction showing transverse matrix damage effect with a linear shape - ITR = 2: exponential

shape (Figure 7)

Figure 7. Tensile test in transverse direction showing transverse matrix damage effect with an exponential shape - ITR = 3: tabulated

shape (Figure 8)Where, is the function identified by IFUNCD2.

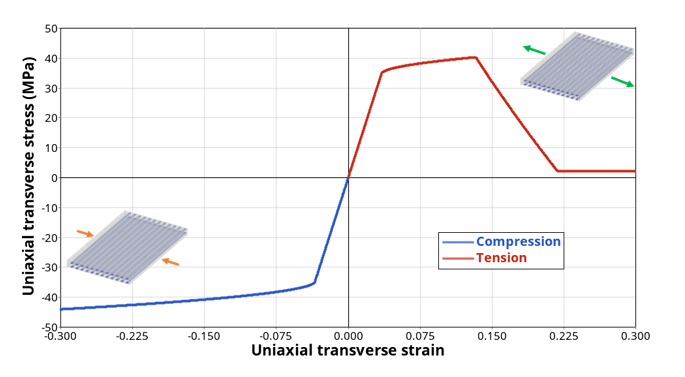

Figure 8. Tensile test in transverse direction showing transverse matrix damage effect with a tabulated shapeThis damage variable is supposed to occur in tension only. In compression, the microcracks of the matrix are assumed too close to recover the initial undamaged stiffness (Figure 9). However, for shells only, a specific transverse matrix damage evolution in compression can be described the same way using parameters: , , or IFUNCD2C.

Figure 9. Tension/compression test in transverse directionThis last damage variable affects the stress computation with:(16)

- ITR = 1: linear

shape (Figure 6)

- Fiber damage

affects the behavior along the fiber

direction 1. Under tension loading condition, fiber damage evolves

following the equations.

- The last phenomenon represented in the modified Ladeveze model is

the strain rate dependency. Once again, it is assumed that the viscous

effects are not the same for the fibers and the matrix.

- In fiber direction, the viscosity affects the Young’s modulus

through the introduction of a rate factor denoted

:

(17) Where, is the equivalent strain rate and is the reference strain rate in direction 1.

The rate factor equation can take different shape depending on the value of the flag LTYPE11:- LTYPE11 = 1: power

law

(18) - LTYPE11 = 2: linear

law

(19) - LTYPE11 = 3:

logarithmic law

(20) - LTYPE11 = 4: tangent

hyperbolic law

(21)

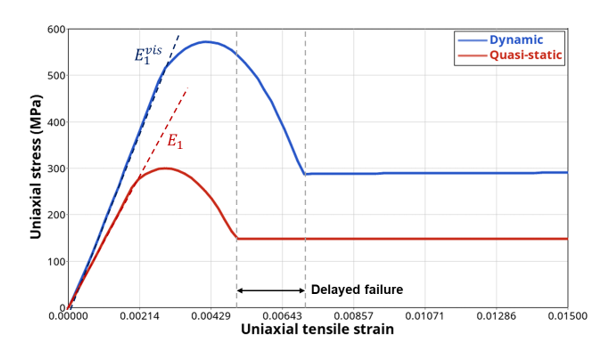

The fibers failure can also be affected by strain rate through the introduction of the factor, whose evolution will also depend on the flag LTYPE11 using parameters and :(22) The expected behavior is detailed below in Figure 10.

Figure 10. Strain rate effect on fibers direction behavior - LTYPE11 = 1: power

law

- In matrix direction, the shear and transverse behavior are affected

by strain rate, as well. The elasticity is then modified with the

introduction of the factors

and

as follows:

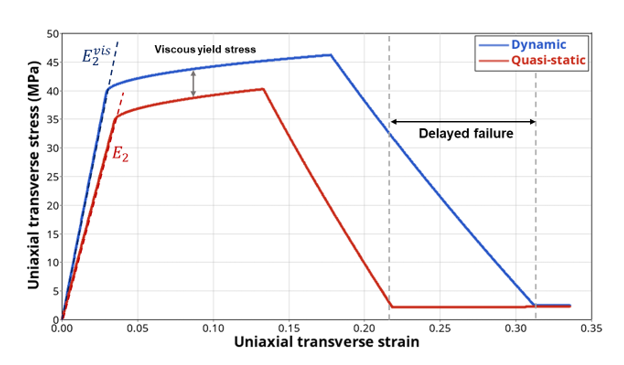

(23) You can notice that the two factors are using the same strain rate reference value and that , and are only modified for solids. The shape of the factors and will be fixed by the flag LTYPE12, and will depend respectively on the values of , and , .

The fracture energy is increased with strain rate, as well, using the same factors:(24) Note: The compression damage parameter for transverse directions and are only modified for shells. - Finally, the last parameter affected by viscous effect is the

initial yield stress, with the use of factor

.

(25) Similarly, the shape of factor is dictated by the flag LTYPER0 using parameters and .

The expected behavior for transverse matrix direction (which is similar for tension and shear) is detailed below in Figure 11.

Figure 11. Strain rate effect on matrix transverse (or shear) direction behavior

- In fiber direction, the viscosity affects the Young’s modulus

through the introduction of a rate factor denoted

: