ACU-T: 3100 Conjugate Heat Transfer in a Mixing Elbow

Tutorial Level: Beginner

Prerequisites

Prior to starting this tutorial, you should have already run through the introductory tutorial, ACU-T: 1000 Basic Flow Set Up

Problem Description

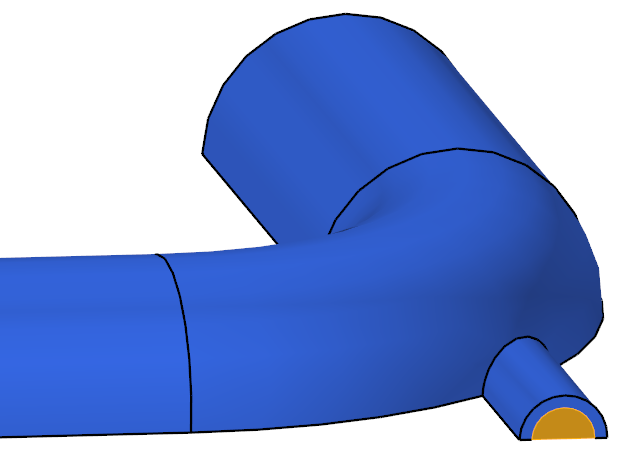

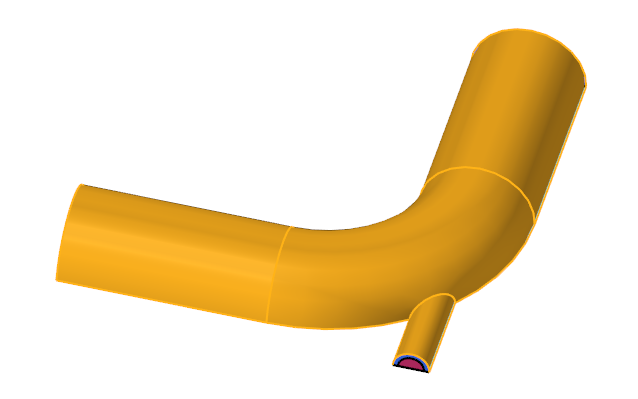

The problem to be addressed in this tutorial is shown schematically in Figure 1. It consists of a mixing elbow made of stainless steel with water entering through two inlets with different velocities and at different temperatures. The geometry is symmetric about the XY midplane of the pipe, as shown in the figure.

Start HyperMesh CFD and Open the HyperMesh Database

- Start HyperMesh CFD from the Windows Start menu by clicking .

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 2.

The Open File dialog opens. - Browse to the directory where you saved the model file. Select the HyperMesh file ACU-T3100_MixingElbowHeatTransfer.hm and click Open.

- Click .

-

Create a new directory named MixingElbow_HeatTransfer and navigate into this directory.

This will be the working directory and all the files related to the simulation will be stored in this location.

- Enter MixingElbow_HeatTransfer as the file name for the database, or choose any name of your preference.

- Click Save to create the database.

Validate the Geometry

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Set Up the Problem

Set Up the Simulation Parameters and Solver Settings

-

From the Flow ribbon, click the Physics tool.

Figure 4.

The Setup dialog opens. -

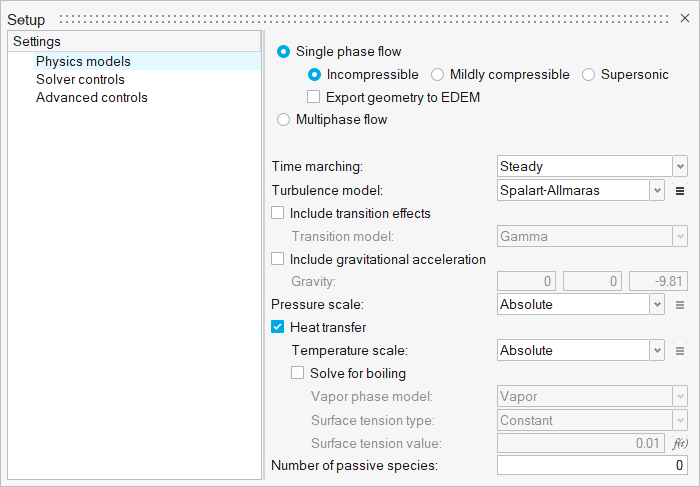

Under the Physics models setting:

Figure 5.

-

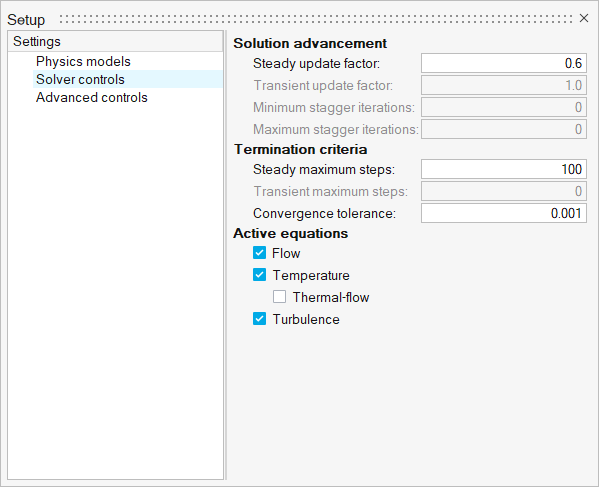

Click the Solver controls setting and verify that the

parameters are set as shown in the figure below.

Figure 6.

- Close the dialog and save the model.

Create a New Material Model

-

From the Flow ribbon, click the Material Library tool.

Figure 7.

The Material Library opens. - Under Settings, click Solid.

-

Click the My Materials tab and then click

to

create a new solid.

A material creation dialog opens.

to

create a new solid.

A material creation dialog opens. -

Rename the material.

- In the top-left of the dialog, click Solid to edit the name.

- Type Steel and press Enter.

-

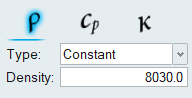

Change the Density value to 8030.

Figure 8.

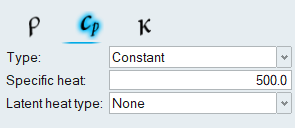

- Click the Specific Heat tab.

-

Change the Specific heat value to 500.

Figure 9.

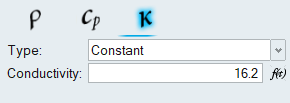

- Click the Conductivity tab.

-

Change the Conductivity value to 16.2.

Figure 10.

-

Exit the material creation dialog.

Figure 11.

- Exit the Material Library.

Assign Material Properties

-

From the Flow ribbon, click the Material tool.

Figure 12.

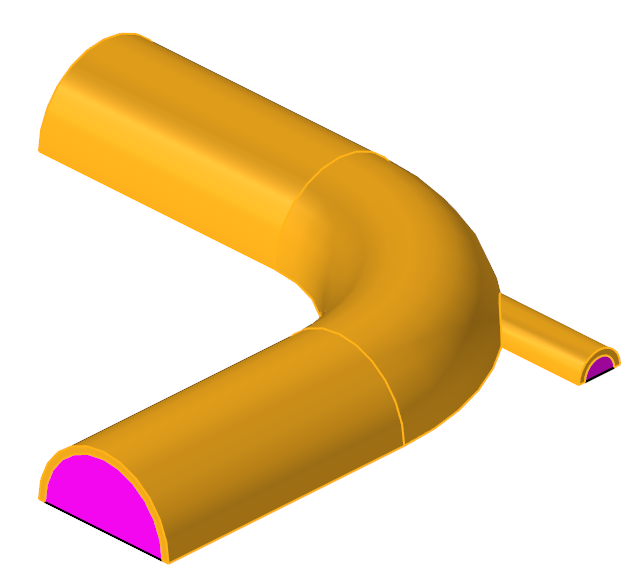

-

Select the outer pipe solid.

Figure 13.

- In the microdialog, click the drop-down menu next to Material and select Steel.

-

On the guide bar, click

to execute the command and remain in the

tool.

to execute the command and remain in the

tool.

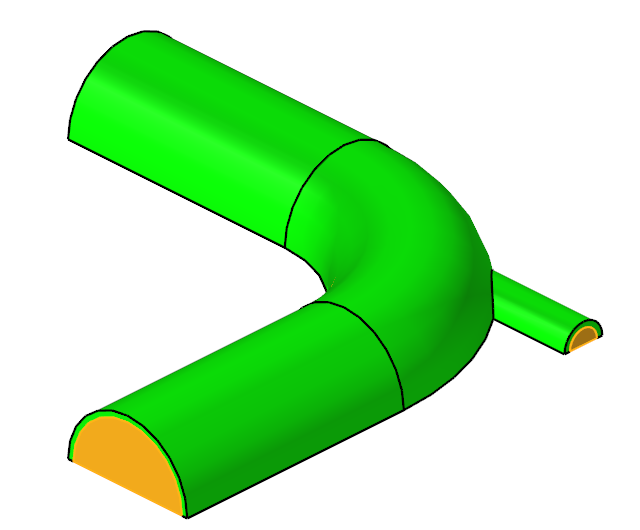

-

Next, select the inner pipe solid.

Figure 14.

- In the microdialog, click the drop-down menu next to Material and select Water.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

Assign Flow and Thermal Boundary Conditions

Set Boundary Conditions for the Large Inlet

-

From the Flow ribbon, Profiled

tool group, click the Profiled Inlet tool.

Figure 15.

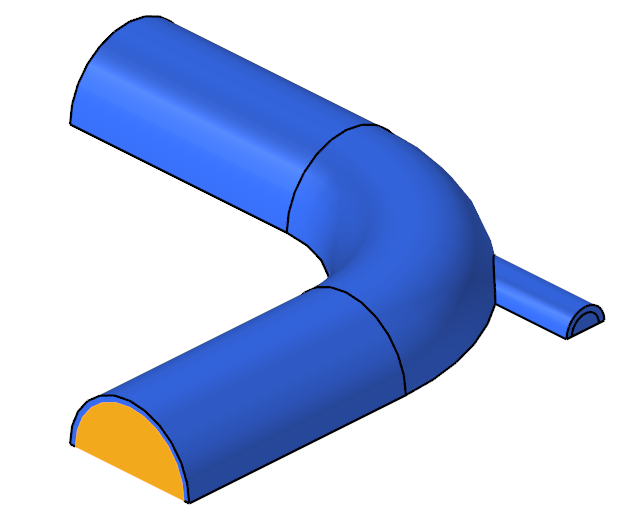

-

Click the face of the large inlet.

Figure 16.

- In the microdialog, enter a value of 0.4 for Average velocity and 295 for Temperature.

-

Rename the inlet.

- From the legend on the left side of the modeling window, double-click Inlet.

- Type Large_Inlet and press Enter.

-

On the guide bar, click

to execute the command and remain in the

tool.

Note: The number of inlets created appears in parenthesis on the top-right of the Profiled tool icon.

to execute the command and remain in the

tool.

Note: The number of inlets created appears in parenthesis on the top-right of the Profiled tool icon.

Set Boundary Conditions for the Small Inlet

-

Click the face of the small inlet.

Figure 17.

- In the microdialog, enter a value of 1.2 for Average velocity and 320 for Temperature.

-

Rename the inlet.

- From the legend on the left side of the modeling window, double-click Inlet.

- Type Small_Inlet and press Enter.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

Set Boundary Conditions for the Outlet

-

From the Flow ribbon, click the Outlet tool.

Figure 18.

-

Click the face of the outlet.

Figure 19.

-

In the microdialog, make sure both

Static pressure and Pressure loss factor are 0.

Figure 20.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

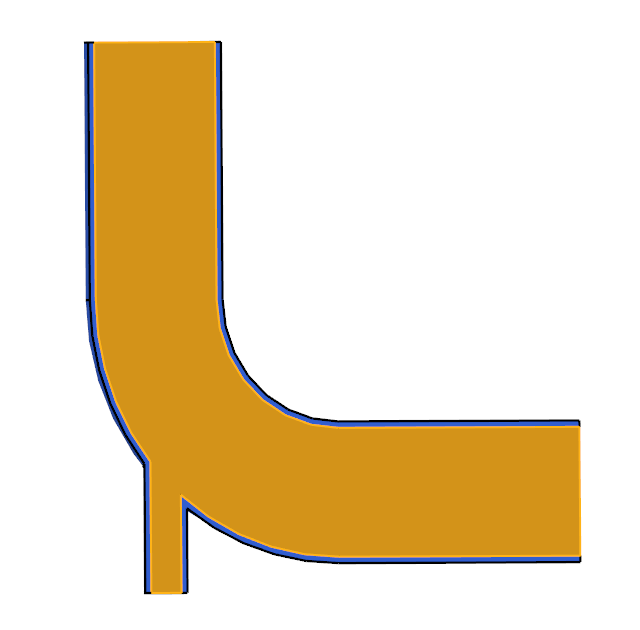

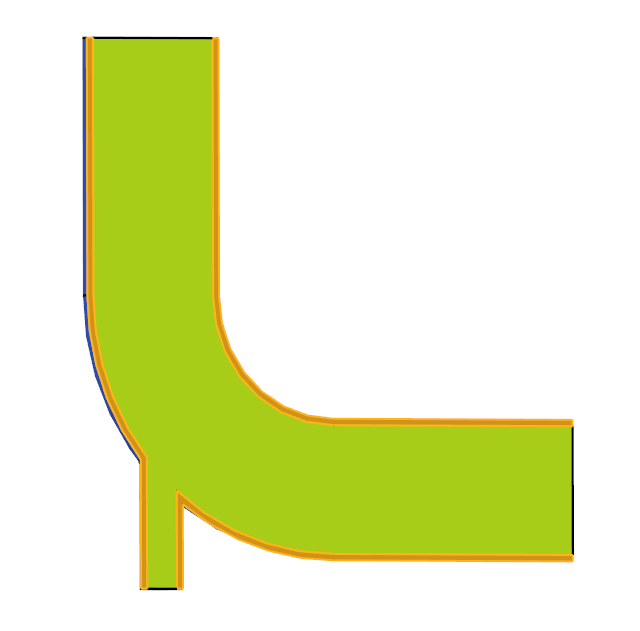

Set Boundary Conditions for the Symmetry Planes

This geometry is symmetric about the XY midplane, and can therefore be modeled with half of the geometry. In order to take advantage of this, the midplane needs to be identified as a symmetry plane. The symmetry boundary condition enforces constraints such that the flow field from one side of the plane is a mirror image of that on the other side.

-

From the Flow ribbon, click the Symmetry tool.

Figure 21.

-

Click the face of the symmetry plane.

Figure 22.

-

In the microdialog, accept the

default symmetry conditions.

Figure 23.

-

On the guide bar, click

to execute the command and remain in the

tool.

to execute the command and remain in the

tool.

-

Next, select the faces for the pipe wall symmetry.

Figure 24.

- In the microdialog, accept the default symmetry conditions.

-

Rename the boundary.

- From the legend on the left side of the modeling window, double-click Symmetry 1.

- Type Pipe_Symmetry and press Enter.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

Set Boundary Conditions for the Outer Pipe Walls

-

From the Flow ribbon, click the No Slip tool.

Figure 25.

-

Click the faces of the outer pipe walls.

Figure 26.

-

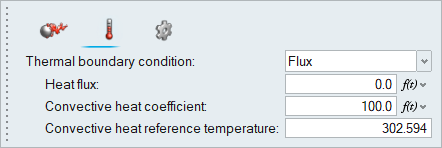

In the microdialog, click

to open

the temperature tab.

to open

the temperature tab.

- Change the Convective heat coefficient value to 100.

-

Change the Convective heat resistance temperature value to

302.594.

Figure 27.

-

Rename the boundary.

- From the legend on the left side of the modeling window, double-click Wall.

- Type Pipe_OuterWalls and press Enter.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

- Save the database.

Generate the Mesh

-

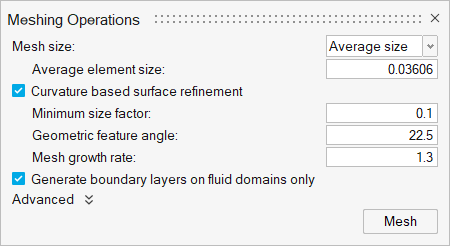

From the Mesh ribbon, click the

Volume tool.

Figure 28.

The Meshing Operations dialog opens.Note: If the model has not been validated, you are prompted to create the simulation model before running the batch mesh. - Check that the Average element size is 0.03606.

-

Accept all other default parameters.

Figure 29.

-

Click Mesh.

The Run Status dialog opens. Once the run is complete, the status is updated and you can close the dialog.Tip: Right-click the mesh job and select View log file to view a summary of the meshing process.

-

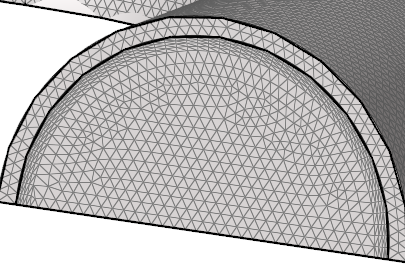

Observe the refined mesh around the pipe walls.

Figure 30.

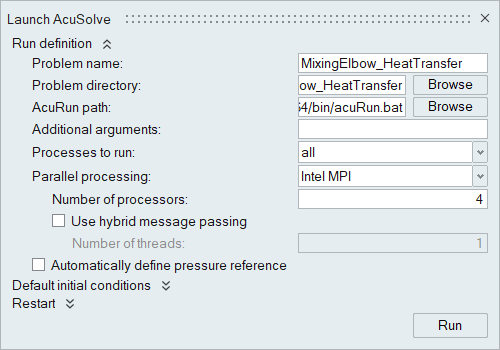

Run AcuSolve

-

From the Solution ribbon, click the Run tool.

Figure 31.

The Launch AcuSolve dialog opens. - Set the Parallel processing option to Intel MPI.

- Optional: Set the number of processors to 4 or 8 based on availability.

- Deactivate the Automatically define pressure reference option.

-

Leave the remaining options as default and click

Run to launch AcuSolve.

Figure 32.

The Run Status dialog opens. Once the run is complete, the status is updated and you can close the dialog.Tip: While AcuSolve is running, right-click the AcuSolve job in the Run Status dialog and select View Log File to monitor the solution process.

Post-Process the Results with HM-CFD Post

- Once the solution is completed, navigate to the Post ribbon.

- From the menu bar, click .

-

Select the AcuSolve

.log file in your problem

directory to load the results for post-processing.

The solid and all the surfaces are loaded in the Post Browser.

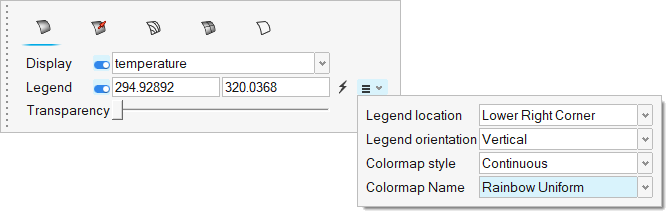

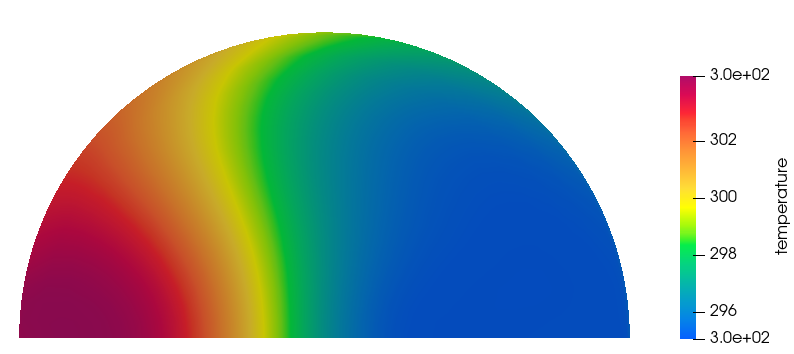

- Isolate the Symmetry flow boundary in the Post Browser.

- Right-click the Symmetry and select Edit.

- In the display properties microdialog, set the display to temperature and activate the Legend toggle.

-

Click

and set the Colormap Name to Rainbow

Uniform.

and set the Colormap Name to Rainbow

Uniform.

Figure 33.

-

Click

on the guide bar.

on the guide bar.

Figure 34.

- Isolate the Outlet flow boundary in the Post Browser.

-

Click the Right face on the View Cube to align the

model.

Figure 35.

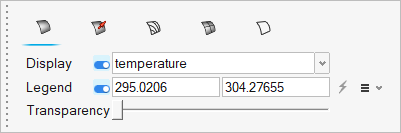

Tip: If the orientation is not the standard, click the face again to re-align the model back to the standard orientation. - Right-click Outlet and select Edit.

- Display the temperature.

-

Click

to reset the range.

to reset the range.

Figure 36.

-

Click

on the guide bar.

on the guide bar.

Figure 37.

Summary

In this tutorial, you learned how to set up a conjugate heat transfer simulation using HyperMesh CFD and how to create a new material model. You launched AcuSolve directly from HyperMesh CFD to compute the solution and then post-processed the results using the Post ribbon.