Extract Midsurfaces

Use the Midsurfaces tool to extract the midsurface of sheet metal stampings, molded plastic parts with ribs, and other parts that have thickness clearly smaller than width and length.

Note: This tool is only available for CAD geometry.

-

From the Geometry ribbon, click the arrow next to the

Create tool set, then select

Midsurfaces.

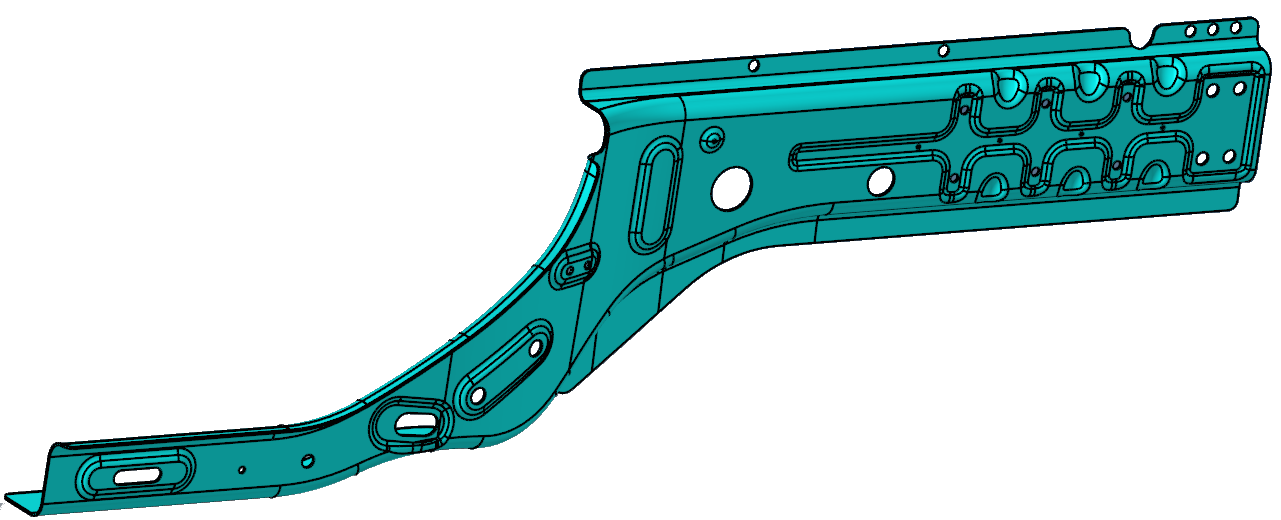

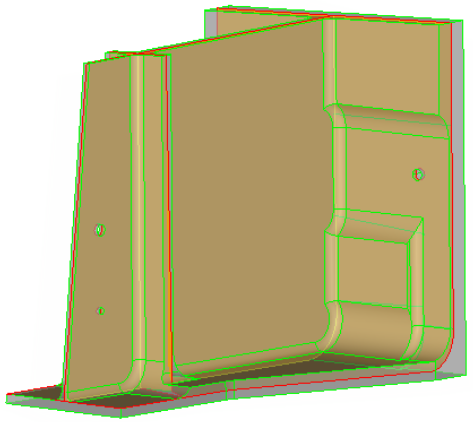

Figure 1.

- Optional:

On the guide bar, click

to define midsurface options.

to define midsurface options.

- Select surfaces or thin solids.

-

Extract midsurfaces.

- Extract the midsurface from all selected solids/surfaces by clicking Midsurface on the guide bar.

- Extract the midsurface from individual solids/surfaces by left-clicking on a selected solid/surface.

Midsurface Method Options

The following methods are available when extracting the midsurfaces of thin solids.

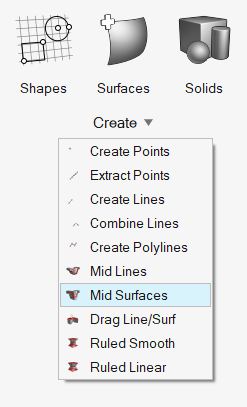

Access this option by clicking ![]() on

the guide bar.

on

the guide bar.

- Planes + Sweeps + Offsets

- Identify the places where a piece of plane or a piece of a sweep surface

can be used as a middle surface. A middle surface is constructed at the

remaining places in the model, for example the places where planar or

sweep surface pieces cannot be used as a middle surface, by the same

algorithm as in offset via the offset of the model's sides.

Figure 2.

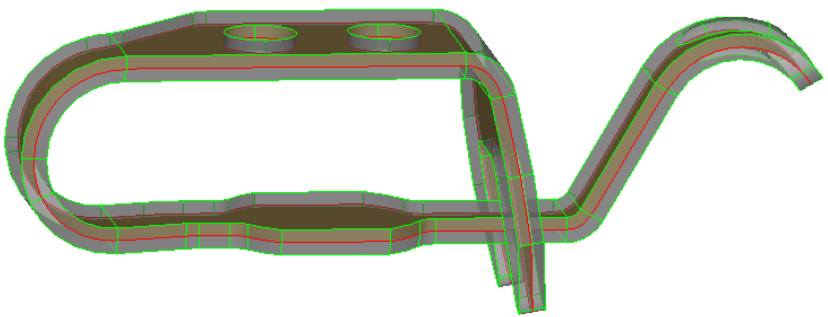

- Planes + Offsets

- Identify the places in the model where a piece of plane can be used as a

middle surface. At the remaining places in the model, for example the

places where planar pieces cannot be used as a middle surface, the same

algorithm as in Offsets is used to construct the middle surface via the

offset of the model's sides.

Figure 3.

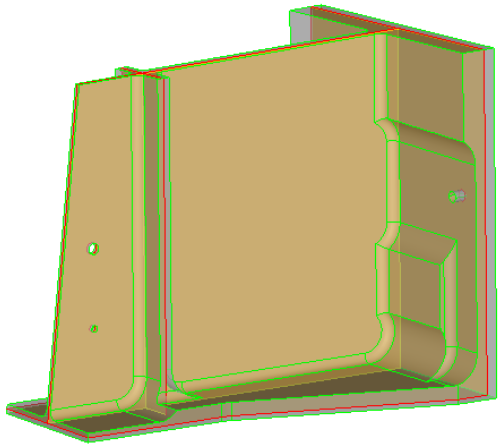

- Offsets

- Create pieces of the middle surface by offsetting the model's side

surfaces towards the middle. This is the traditional approach for

midsurfacing.

Figure 4.

- Skin Offset

- Automatically detects the two largest faces on the model, detects the thickness, and then creates the middle surface by offseting one of the faces towards the other one by half of thickness. This is the quickest method for creating a midsurface. However, it is not applicable to many models.