Shape Optimization Improvements

Overview

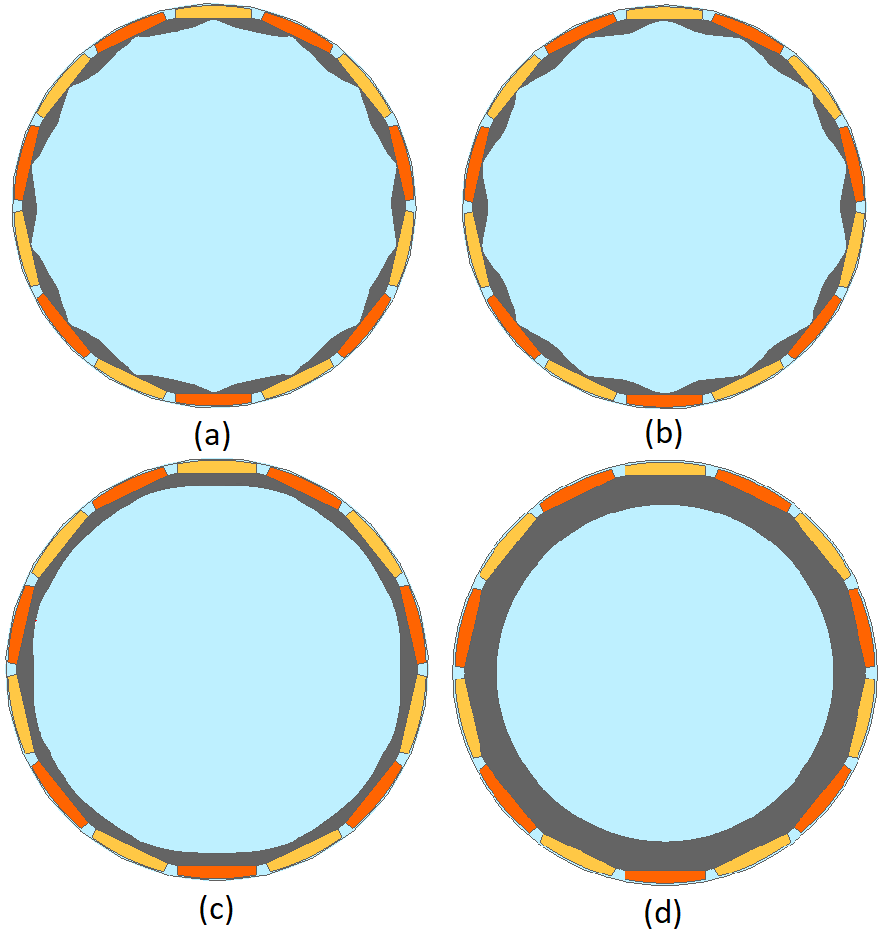

In the shape optimization module, available in Beta mode, it is now possible to use new responses such as the Torque and the Torque Ripple on a mechanical set or the Force on a face region. These new responses are all computed with the Virtual Works and allow to reduce drastically the computation time of a Shape Optimization. A new feature has also been developed and offers the possibility to go further with a Shape Optimization process, this new Feature is the Remeshing option that may be set in the Run Shape Optimization GUI. This option allows to do more iterations avoiding the cancelling of the optimization due to a too distorted mesh by inserting nodes during the solving process.

Example of application

- Keep the same mean torque value as the initial design,

- Constrain the torque ripple under a given threshold,

- Reduce the rotor volume as much as possible for the iron parts,

- Keep the symmetry of the rotor’s design.

| Physical Characteristics | Value |

|---|---|

| Torque of the rotor | 5.1 Nm |

| Torque ripple of the rotor | 5.1 % |

| Volume of the iron parts in the rotor | 2.3E-05 m3 |

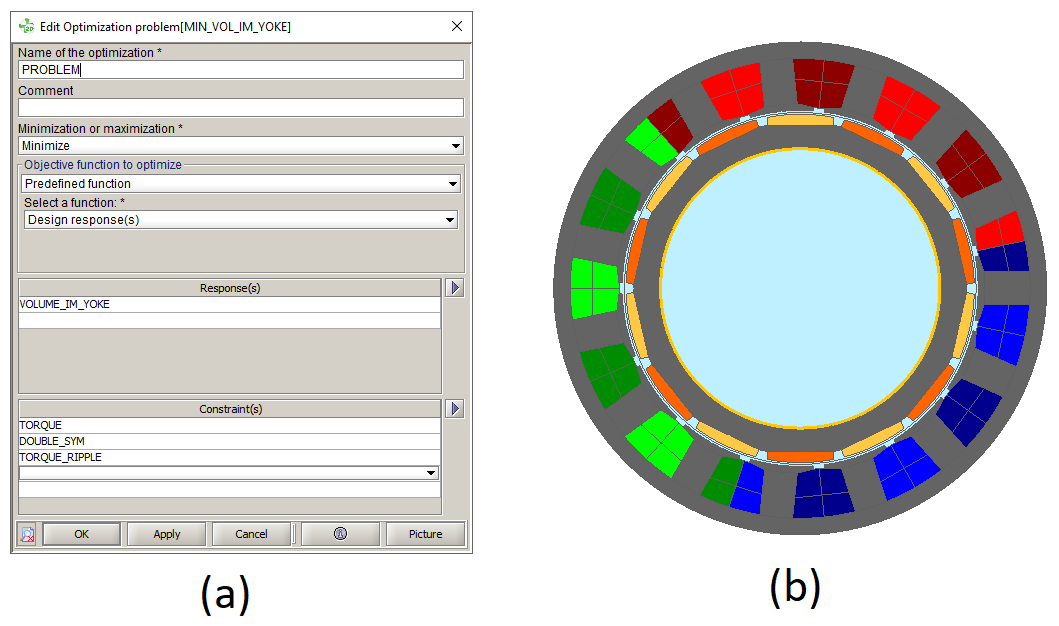

To run the shape optimization, a response for the Torque must be created to be used for keeping its average value by constraints. Another response for the Torque Ripple to constrain it must be created too. Creating a Torque response requires to select the response Torque on a mechanical set (virtual works); for the torque ripple, we use the Torque ripple on a mechanical set (virtual works). Both are applied on the Rotor mechanical set. A main criterion of this optimization is to accept a deviation of the Torque and of the Torque ripple around 5% from the initial design.

A Volume of 2D faces is created in the Responses menu and is applied on the iron parts of the rotor in the electrical machine.

A Double axis symmetry is also created in the Constraints menu and is applied on the X and Y axes of the finite element domain.

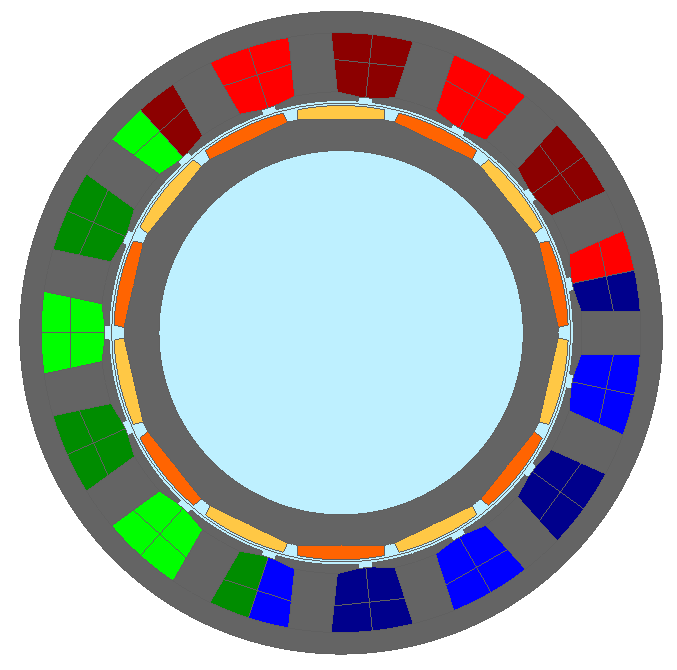

Finally, to set the optimization problem up, the Objective function is set as the Volume of the iron parts in the rotor as shown in Figure 2 - (a). The shape optimization is run on the iron parts of the rotor, and the air gap boundary, as illustrated in Figure 2 – (b) by the highlighted lines.

This optimization has been settled with the Flux Computation Distribution Engine that allows to distribute the optimization over ten Flux in parallel.

To compare the results and the computation time given the Virtual Works and the Maxwell's Tensors, the same problem runs with both approaches, with and without remeshing:

| Initial design | Virtual works & remeshing | Maxwell's tensors & remeshing | Virtual works without remeshing | |

|---|---|---|---|---|

| Mean torque value | 5.1 Nm | 4.91 Nm | 4.90 Nm | 4.95 Nm |

| Torque ripple | 5 % | 4.88 % | 5.1 % | 4.6 % |

| Volume of the iron parts in the rotor | 2.2997e-05 m3 | 7.163e-06 m3 | 6.989e-06 m3 | 8.903e-06 m3 |

| Number of iterations | / | 38 | 18 | 9 |

| Optimization time (distribution with ten Flux en parallel) | / | 1 hour | 2 days and 4 hours | 20 minutes |