Tutorial: Charge Weld Length

Tutorial Level: Beginner Learn how to compute Charge Weld Length by analyzing a model's post-processing information.

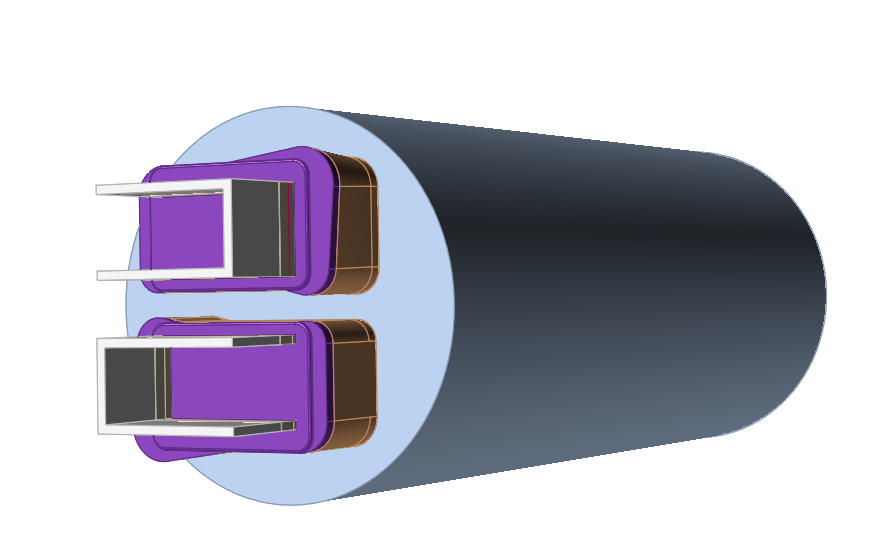

When extruding multiple billet cycles, the new billet material welds with material left in the pockets and feeder plate from previous extrusions. The quality of the material in this zone may not be acceptable and is usually sheared off. This sheared-off region, known as butt length, can be computed by performing billet interface tracking analysis in HyperXtrude. Billet interface tracking is performed as a transient analysis.

Load Model

Select the Material

-

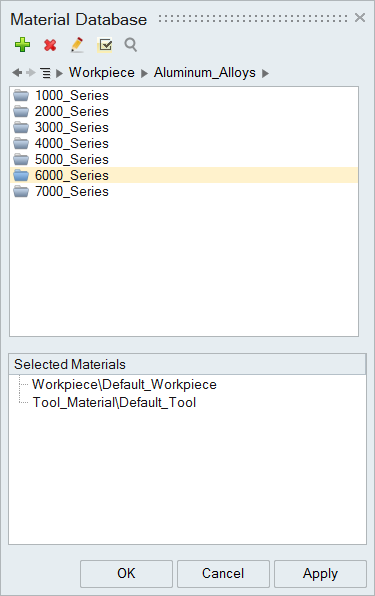

Click the Materials icon.

-

Select the Workpiece alloy

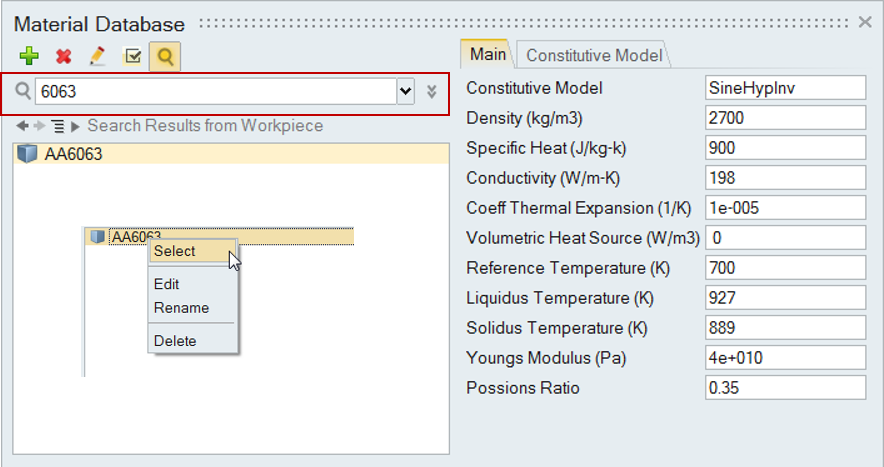

Note:You can search directly for the material by clicking the search box and typing the name of the alloy.

-

Right-click on the alloy name, and click Select.

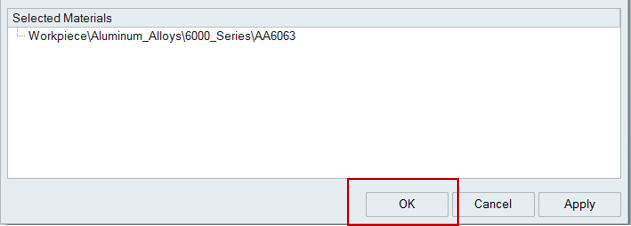

The chosen alloy is added to the Selected Materials pane.

Note: To deselect a material there, right-click and click Deselect. - Click OK to close the Material Database.

-

Click to save the model at the desired location.

Note: It is recommended that you always save the model file in a newly created folder to avoid conflict with older/existing model files.

Specify Process Parameters and Simulate

-

Click the Submit job for analysis icon to run the

simulation.

-

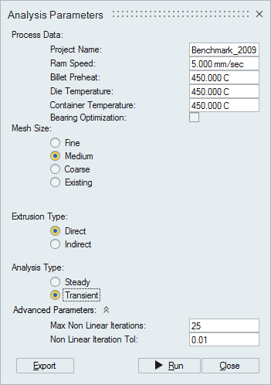

In the Analysis Parameters window that pops up, enter

values as shown.

- Click the Run button.

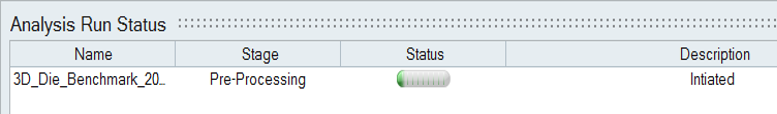

| Status after submitting the job |

|

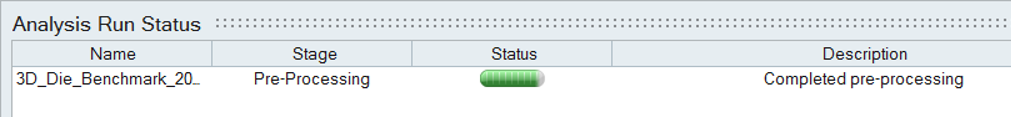

| Status after meshing is completed |

|

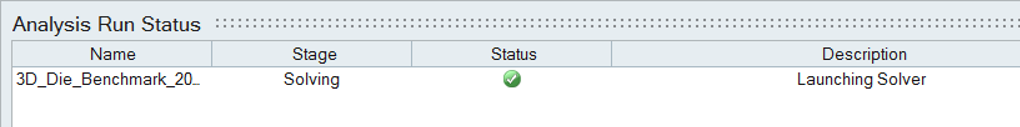

| Status when job is running in the solver |

|

Review the OUT File

The goal of post-processing is to understand the performance of the die. This is accomplished by studying the material flow and heat transfer in the model in HV. Before doing the detailed post-processing in HV, inspect the OUT file to get a quick overview of the results.

- Open the *.out file in a text editor.

- Inspect all data, applying the steps as outlined in the post-processing section.

Analyze the WLD File

-

Open the *.wld file from the working folder.

This is an ASCII file, and you can use any text editor to view this file.

-

Review the data and verify.

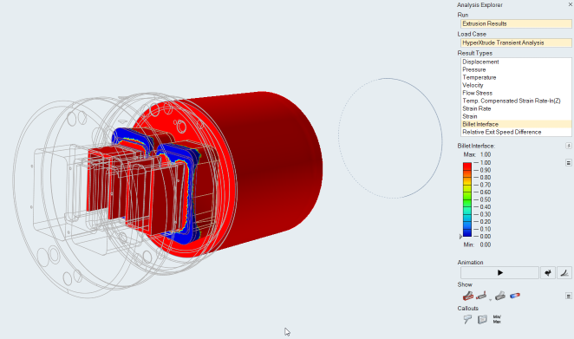

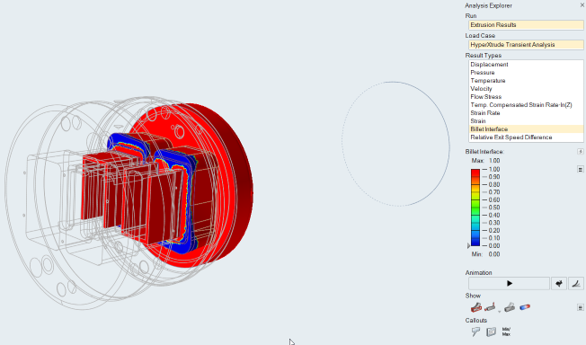

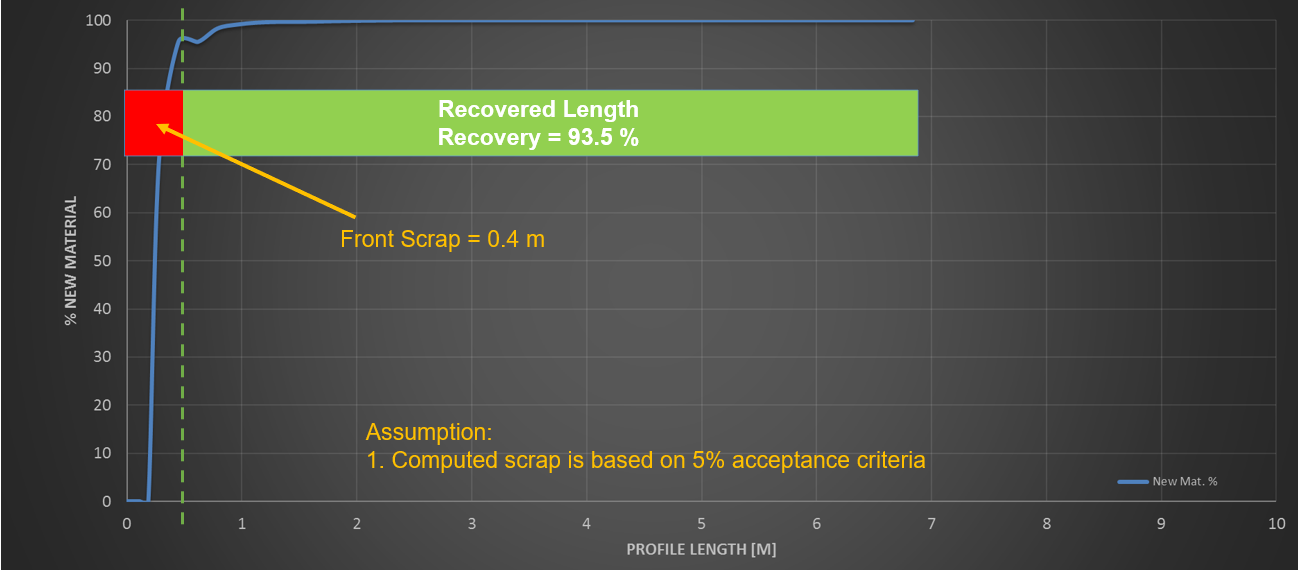

During Ram acceleration time, no new material is present on the exit surface. As extrusion progresses, the percentage of new billet material on the exit surface increases. After 6.85 seconds of extrusion (7th time step), the exit surface contains all new material.Note: The assumed cutoff value is 95%. Profile with more than 95% is considered acceptable.

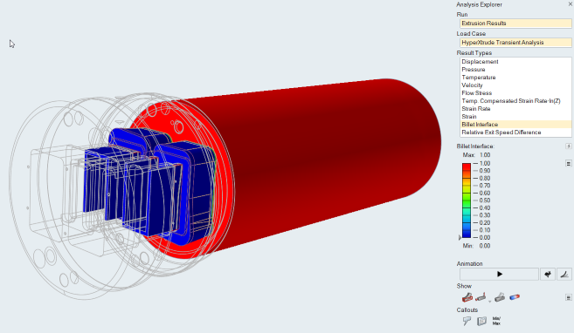

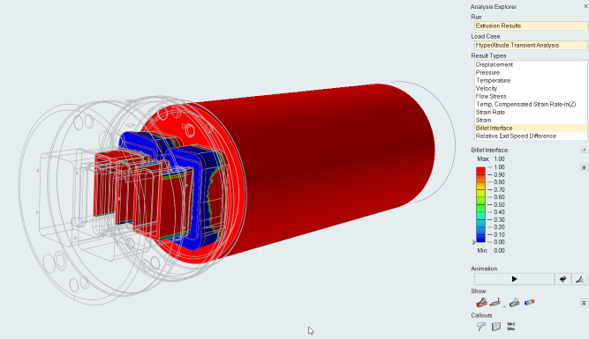

View Simulation Results