Tutorial: Grounded Fastener Optimization

Enable grounded fastener optimization to improve load distribution into the supports.

- Set up and run a baseline analysis of a hanger bracket to establish realistic design targets

- Create a defeatured model to set up and run a standard topology optimization

- Enable fastener optimization to improve load distribution into the supports

Overview: Fastener Load Optimization

Evenly distributing or limiting the maximum force in all bolts, screws, and other connections in a structure is a common aim of good design practice. When structures become complex in shape or loading, it can be difficult to achieve this objective. One approach is to use topology optimization to redistribute material away from direct load paths so that underutilized fasteners carry more of the applied load. Inspire provides the ability to constrain the load in a grounded screw or grounded bolt to achieve improved load distribution in a structure.

- In many structures, loads are not uniformly applied and geometry is often non-symmetric. This can lead to large variations in the forces that the fasteners and connection points carry.

- Changing the topology of the structure will change the amount of load in each fastener.

- By limiting the maximum load in a fastener or set of fasteners, the topology generated by Inspire can more evenly distribute the resultant forces, reducing the maximum stresses and helping torque retention.

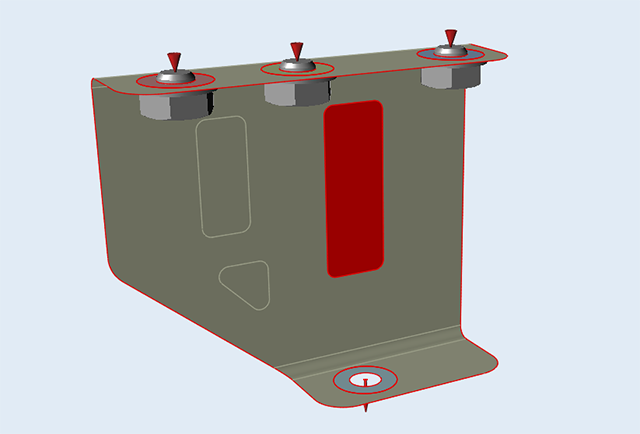

Set up the Hanger Model

- Press F7 to open the Demo Browser.

-

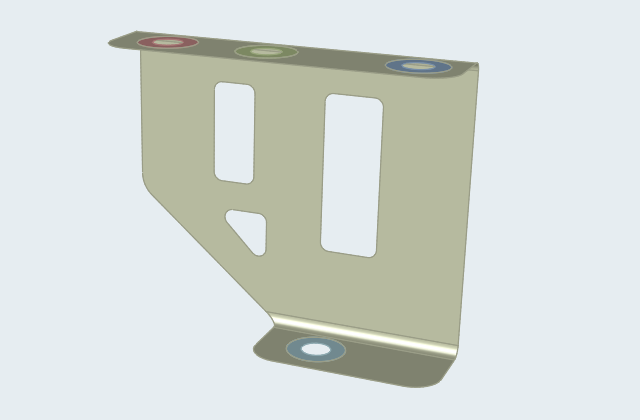

Double-click the hanger_geometry.stmod file to load it in

the modeling window. This is a surface model of a typical hanger bracket. Note

that all parts have a 4 mm thickness assigned, but there are no loads or

supports in the model.

- Make sure the display units in the Unit System Selector are set to MPA (mm t N s).

-

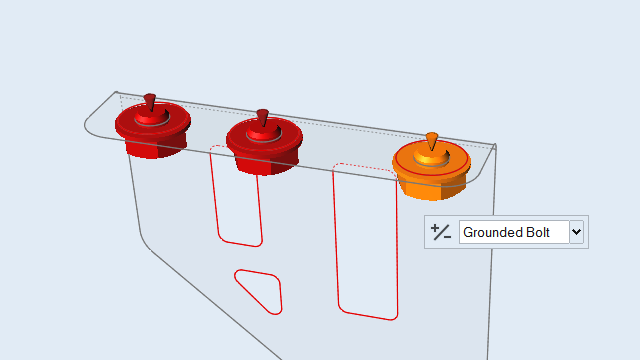

Select the Fasteners tool on the

Structure ribbon.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

Select the Single Holes and Grounded

Bolt options on the guide bar.

-

Choose the three red edges on the bosses (B1, B2, and B3) and use the +/-

option on the microdialog to orient the grounded bolts as shown.

Note: Note that using grounded bolts means there is no need to separately define supports on these fasteners.

Note: Note that using grounded bolts means there is no need to separately define supports on these fasteners. -

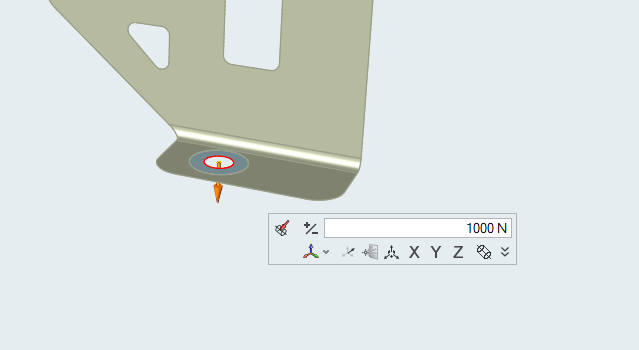

Select the Forces tool on the Loads

icon.

-

Apply a force of 1000 N to part B4 in the Y direction as shown.

- Right-click and mouse through the check mark to exit, or double-right-click.

Run a Baseline Analysis

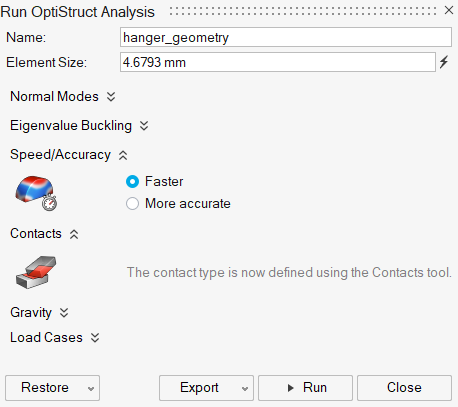

-

Click Run Analysis

icon on the Structure ribbon.

icon on the Structure ribbon.

-

Set the options in the Run Analysis window as shown

below:

Note: Make sure that Speed/Accuracy is set to Faster.

Note: Make sure that Speed/Accuracy is set to Faster. - Click Run to perform the analysis.

-

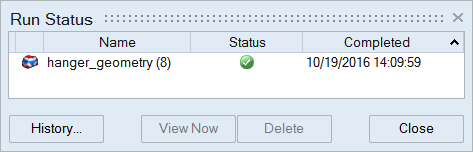

When the run is complete, double-click on the name of the run to view the

results.

-

When the run is complete, double-click on the name of the run to view the

results.

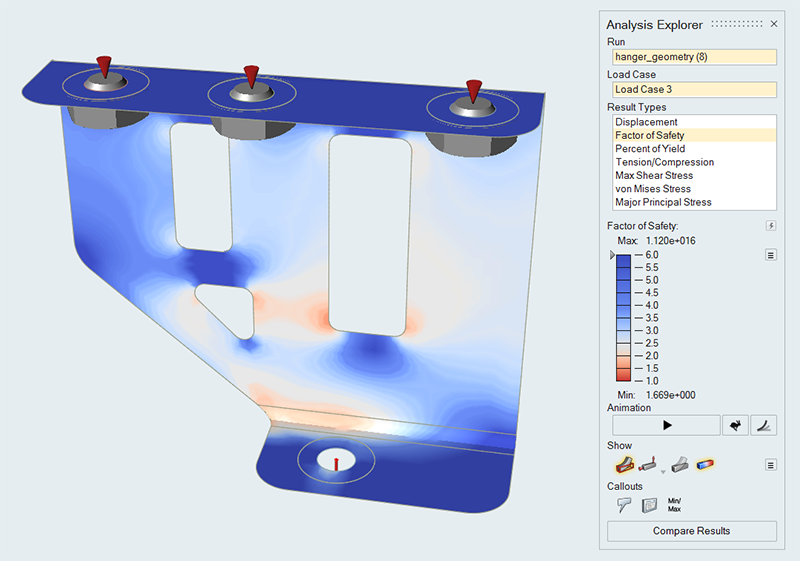

- In the Analysis Explorer, examine the results and note that the minimum factor of safety is 1.669.

- Switch to the Displacement result type.

- Select Hide All Loads and Supports under the Show icons.

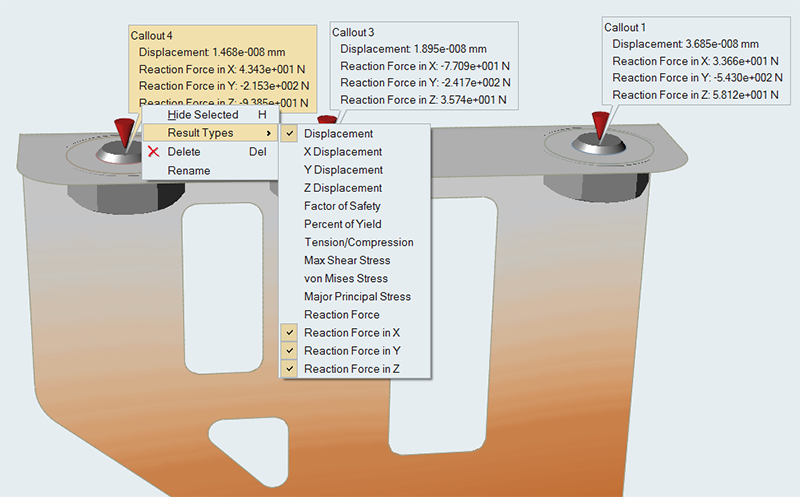

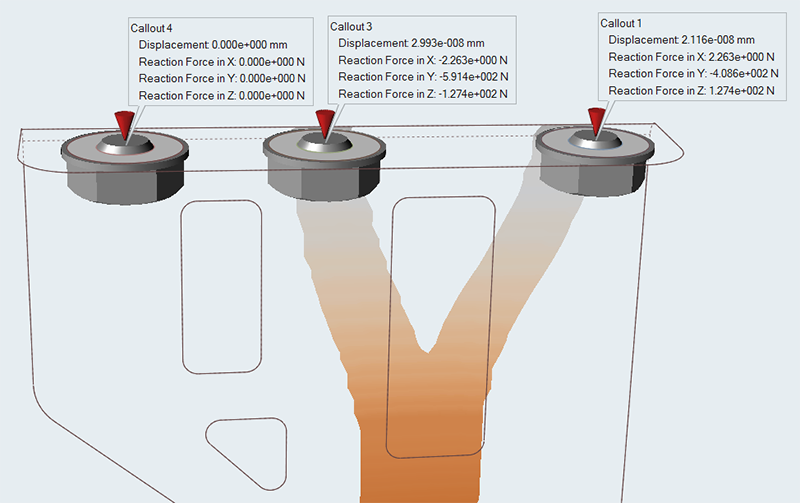

- Create a callout at the center of each grounded fastener hole.

-

Right-click on each callout, select Result Types from

the context menu, and add Reaction Forces in

X, Y, and Z.

-

Select Show All Loads and Supports under the Show

icons.

Note that the Z coordinate is along the axis of the hole.

- Double-right-click to exit the Analysis Explorer.

Prepare the Model for Topology Optimization

The best starting point for topology optimization is a design region without any predefined cutouts. In many cases, the patch tool can be used to fill holes in surface models.

- Either open the hanger_run.stmod file from the Demo Browser or continue with your model from the previous step.

-

Select the Patch tool on the

Geometry ribbon.

-

Click the edge of each cutout to remove it from the bracket, as shown.

-

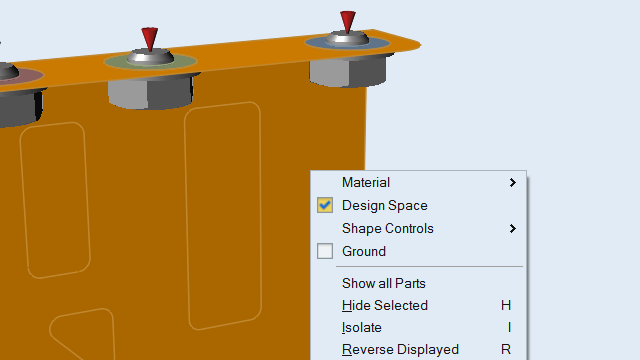

Right-click the bracket and designate it as the design space.

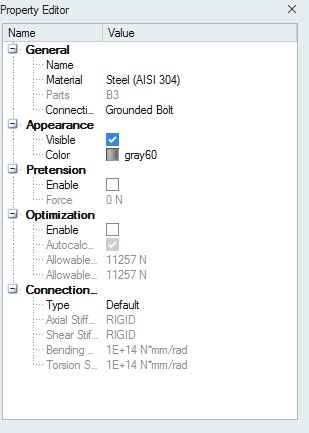

Run a Topology Optimization

-

Click Run Optimization

on

the Optimize icon on the Structure

ribbon.

on

the Optimize icon on the Structure

ribbon.

-

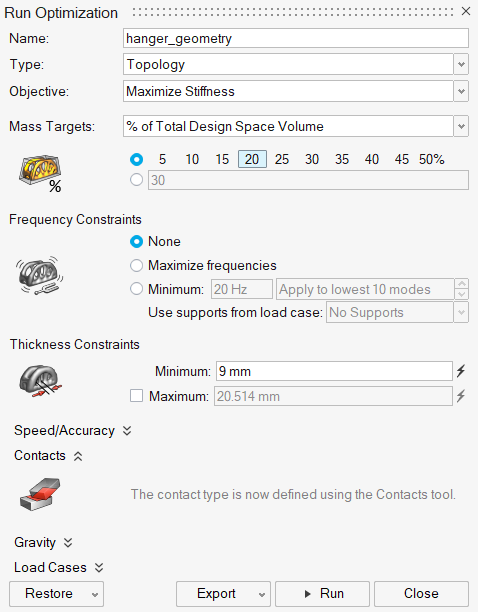

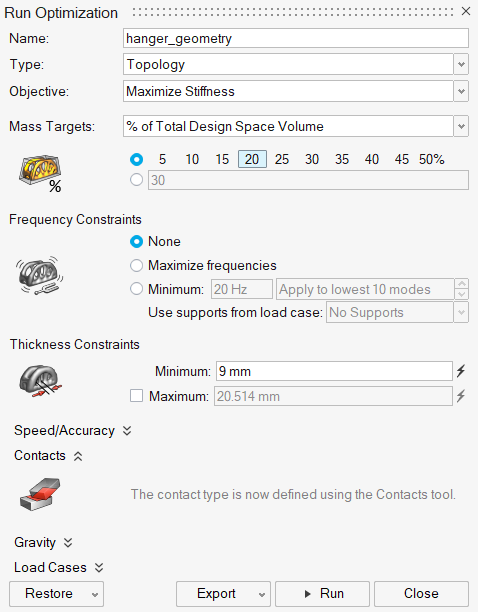

Set the options in the Run Optimization window as shown

below:

- Select Topology for the Run type.

- Select Maximize Stiffness for the Objective.

- Set a Mass target of 20%.

- Enter a Minimum Thickness constraint of 9 mm.

- Click Run to perform the optimization.

- When the run is complete, double-click on the name of the run to view the results.

-

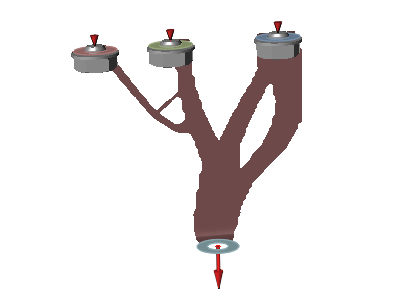

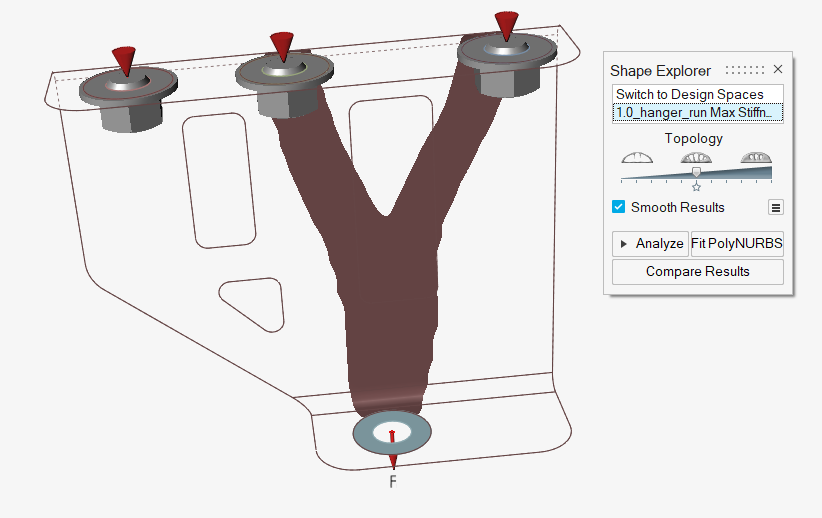

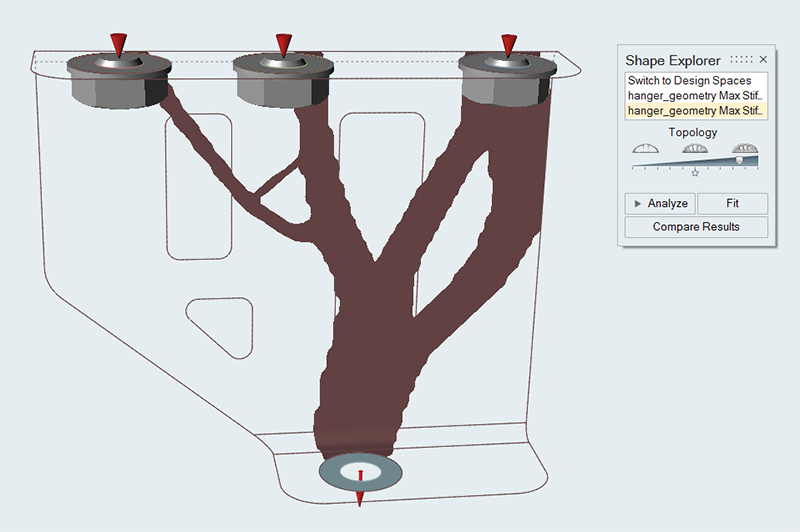

In the Shape Explorer, examine the results. Note how the optimization

distributes the material for most direct attachments to ground.

-

Click the Analyze button on the Shape Explorer to run a

re-analysis.

-

After loading the results, the callouts that were defined earlier should still

be active. Note how the reaction force in the Z direction for the center and

rightmost bolt have changed.

Define Maximum Bolt Loads

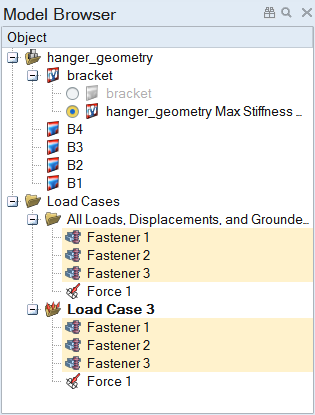

- Either open the Hanger_opti_run.stmod files from the Demo Browser or continue with your model from he previous step.

-

Hold Ctrl and select the three grounded bolts in the

Model Browser.

-

Open the Property Editor (F3) and select the Enable

option under Optimization.

-

Deselect the Autocalculate Allowable Forces

option.

Inspire defaults to Autocalculate Allowable Forces. This value is based on the yield stress of the fastener material and the fastener cross section.

- Enter 444 N for both the Allowable Axial Force and the Allowable Shear Force. The goal is to get more even force distribution in the grounded fasteners.

Repeat the Topology Optimization

-

Click Run Optimization

on

the Optimize icon on the Structure

ribbon.

on

the Optimize icon on the Structure

ribbon.

-

Repeat the optimization using the same settings as before.

-

Load and examine the results. Adjust the slider so that all the parts are

connected. Note how the optimization now distributes the material to all three

grounded bolts.

-

Click the Analyze button on the Shape Explorer to run a

re-analysis.

- After loading the results, the callouts that were defined earlier should still be active. Note that all of the bolts now carry some load, and the maximum on the center bolt is below the defined maximum of 444 N. (Your specific results will vary based on where you positioned the topology slider before running the reanalysis.)