OS-V: 0240 3D Steel Roller on Rubber

Contacts Benchmark 5For quasi-static analysis using linear elastic material, geometric non-linearity and nonlinear boundary conditions.

Model Files

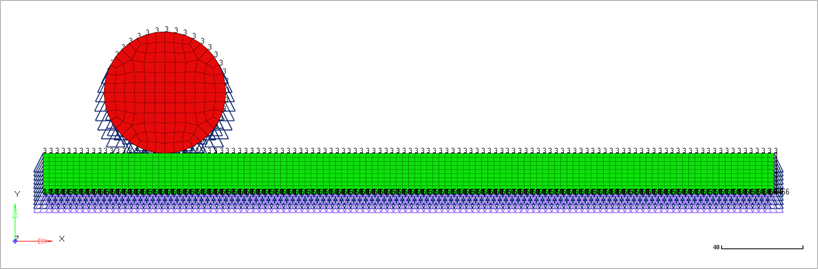

Benchmark Model

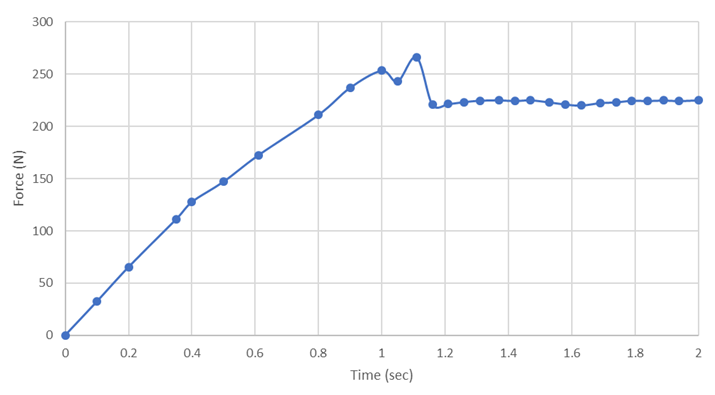

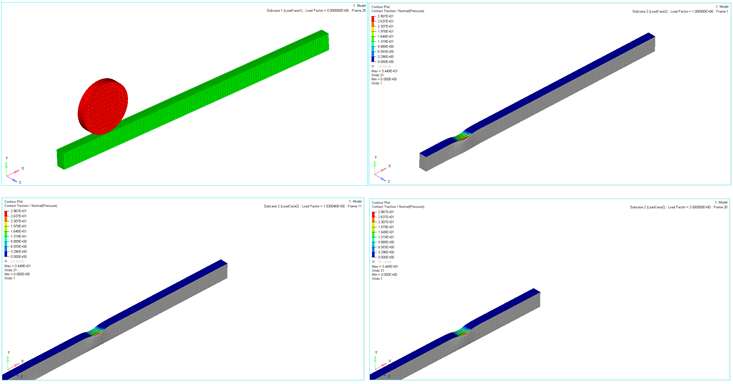

Hexa8 elements are used to create one half of the model. The steel is of 20 mm width and 30 mm radius, the rubber mat is 22 mm wide, 20 mm in high and 360 mm long. The steel roller starts rolling from a point 60mm from the left-hand side of the rubber mat. The center of the roller is fixed in horizontal and vertical direction, for a time period of 0-1 second the bottom surface of the rubber is displaced 3mm in the negative y direction, the sheet x-displacement is fixed and there is no roller rotation. For the time period of 1-2 second the bottom surface of the rubber sheet is held at 3 mm y-displacement and rotation of 360 degrees is prescribed to the steel roller where the sheet is free to move in horizontal direction. There is no force applied on the system and the coefficient of friction between the two surface is 0.3. The nodes on the outer surface of the roll are selected as main nodes, while the nodes on the top surface of the mat are specified as the secondary nodes.

- Material Properties

- Value

- Esteel

- 210 kN/mm2

- Nsteel

- 0.3

- C10, rubber

- 10 N/mm2 (Neo Hookean material description)

- D1rubber

- 0.0001

Nonlinear Static Analysis Results

| Horizontal Displacement (mm) | NAFEMS | OptiStruct | Normalized |

|---|---|---|---|

| 3D first order elements | 182.9 | 182.06 | 1.00461386 |

Reference

NAFEMS R0094 - Advanced finite element contact benchmarks, Konter 2006