Altair Flow Simulator 2025 Release Notes

Highlights

- Flow Simulator API

- GUI dark mode

- Solver accuracy improvement for real gasses

New Features

- Flow Simulator API

- The Flow Simulator solver can now be run from a user-defined program using a set of functions to load and run a Flow Simulator model. A dynamic link library (DLL) file containing the Flow Simulator solver can be linked to a user-defined program. Several simple functions are available so that the user-defined program can interact with the Flow Simulator model: FS_LOAD_MODEL, FS_RUN_MODEL, FS_GET, FS_SET, and FS_END. C, C++, and Fortran programing languages have been tested and examples are supplied with the Flow Simulator installation (<install_directory>/FlowSimulator/Resources/Solver_API_Examples).

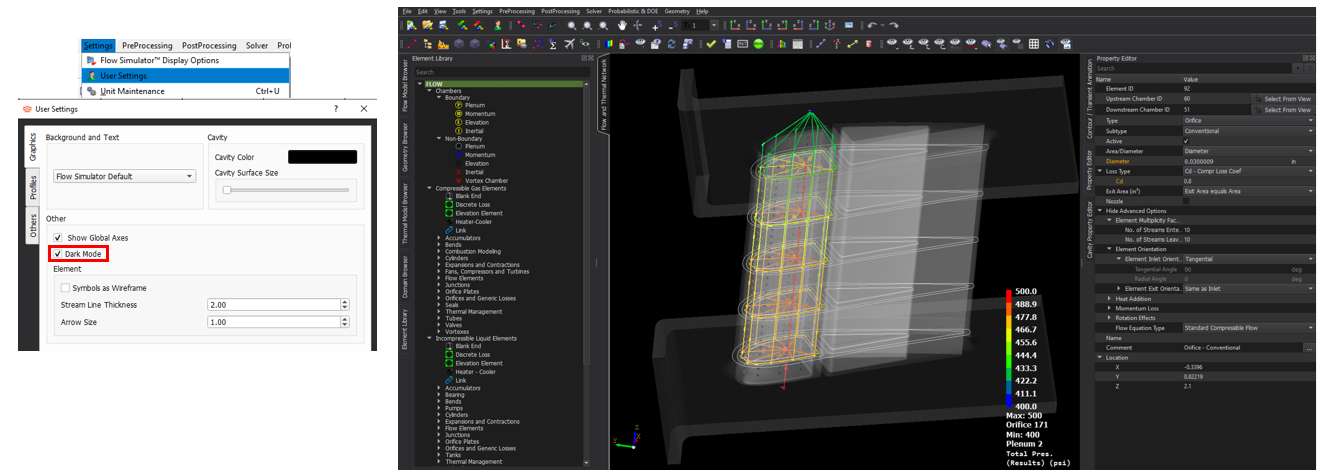

- GUI Dark Mode

- The Flow Simulator GUI display can be toggled to dark mode. The dark mode

uses a black background with lighter text colors.

Figure 1. GUI Dark Mode

Enhancements

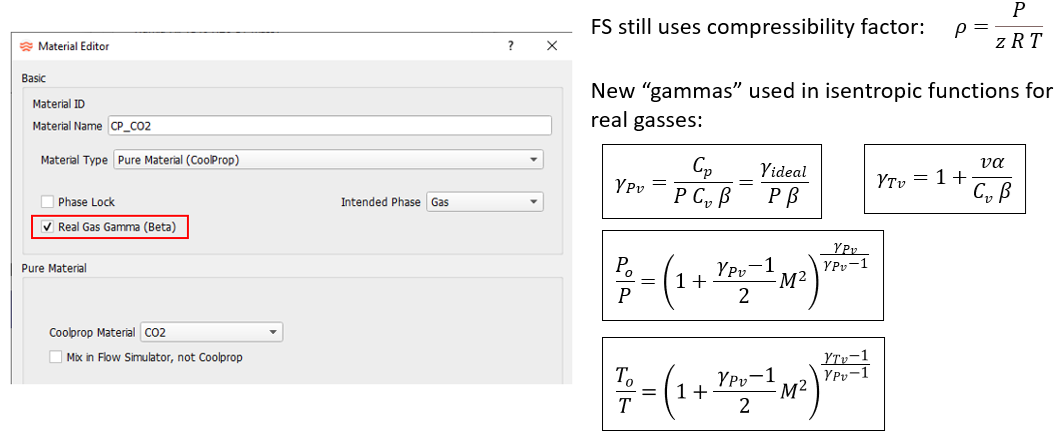

- Solver Accuracy Improvement for Real Gasses

- Since version 2022, Flow Simulator has used the compressibility factor, z, to adjust the ideal gas relationship for density. The compressibility factor improves the accuracy for fluids that are at pressures and temperatures where they do not behave like an ideal gas.

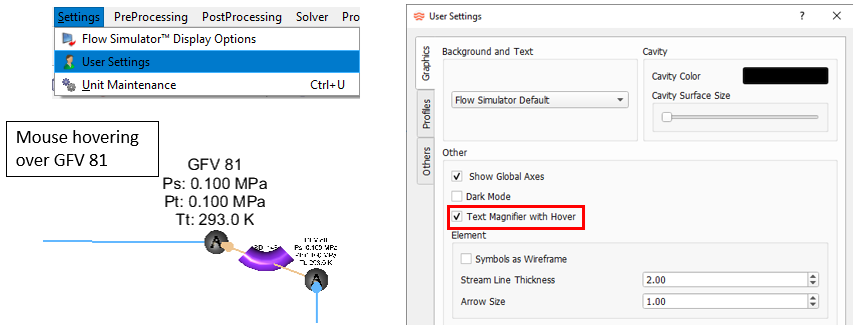

- Text Magnified During Hover

- An object’s text can be magnified temporarily when the mouse pointer is on

the object. This is useful if the text size is too small to read at the

current zoom level or model scale. You can toggle this behavior in the User

Settings.

Figure 3. Text Magnified During Hover

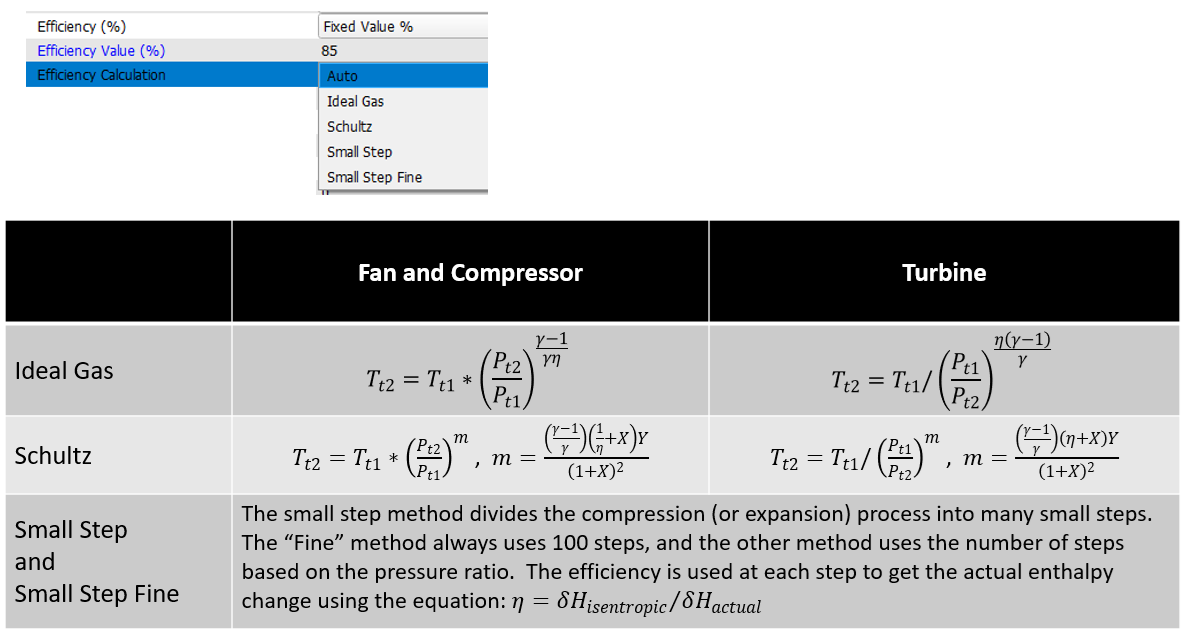

- Fan, Compressor, and Turbine Efficiency Calculations

- The total temperature exiting a fan, compressor, or turbine is a function of

the total pressure change and polytropic efficiency of the component. The

calculation methods have been updated to consider real gas effects. If real

gas effects are required, the Schultz or Small Step method should be used

for an accurate exit temperature. The Small Step method is the most accurate

but can also increase solver run times. The Schultz method is less accurate

but is fast. The “Auto” method is the default. It uses the standard ideal

gas equations for ideal gasses and the Schultz method for real gas. Coolprop

must be the fluid property source for the Schultz and Small Step

methods.

Figure 4. Fan, Compressor, and Turbine Efficiency

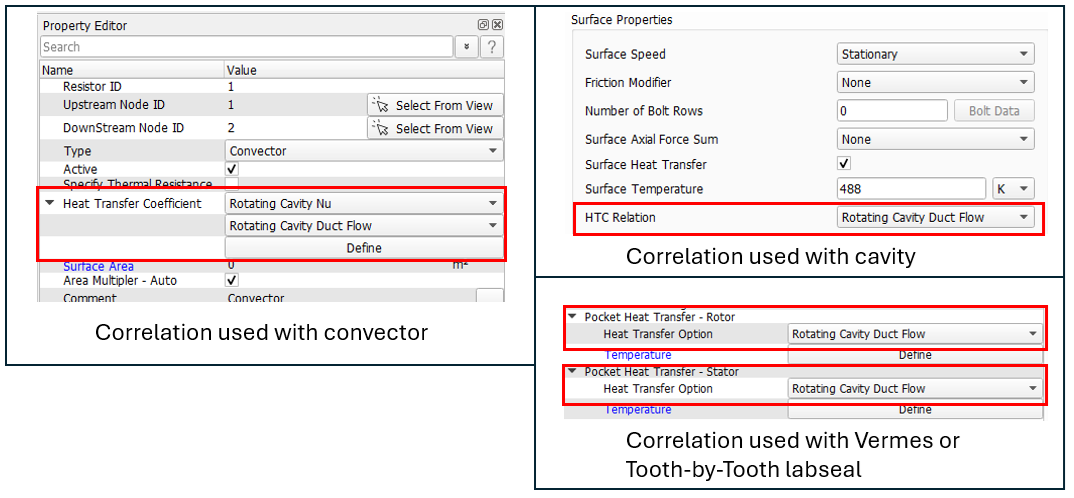

- Heat Transfer Coefficients (HTC) for Rotating Cavities

- Four new HTC correlations for rotating surfaces have been added. These

correlations are useful for rotating machines such as gas turbines and

electric motors.

- Rotating Cavity Using Duct Flow: Uses the Dittus-Boelter duct flow

correlation for general cavities with rotating flow and surfaces.

Figure 5. Rotating Cavity Using Duct Flow

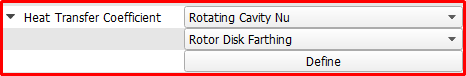

- Rotor Disk with Bore Flow: Correlation for cavities typically found

in gas turbine compressors. Use correlation on rotating disk

surfaces with axial flow at the bore. The correlation can be used

with convectors and is based on the paper by P.R. Farthing.

Figure 6.

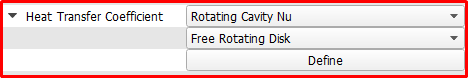

- Free Rotating Disk: Use this HTC correlation on an isolated rotating

disk. An isolated disk has no through flow, other than the flow

induced by the disk rotation, and the far field ambient fluid has no

swirl. The correlation can be used with convectors.

Figure 7.

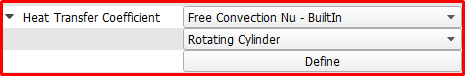

- Free Rotating Cylinder: Use this HTC correlation on the inner or

outer surface of a rotating cylinder. The correlation can be used

with convectors.

Figure 8.

- Rotating Cavity Using Duct Flow: Uses the Dittus-Boelter duct flow

correlation for general cavities with rotating flow and surfaces.

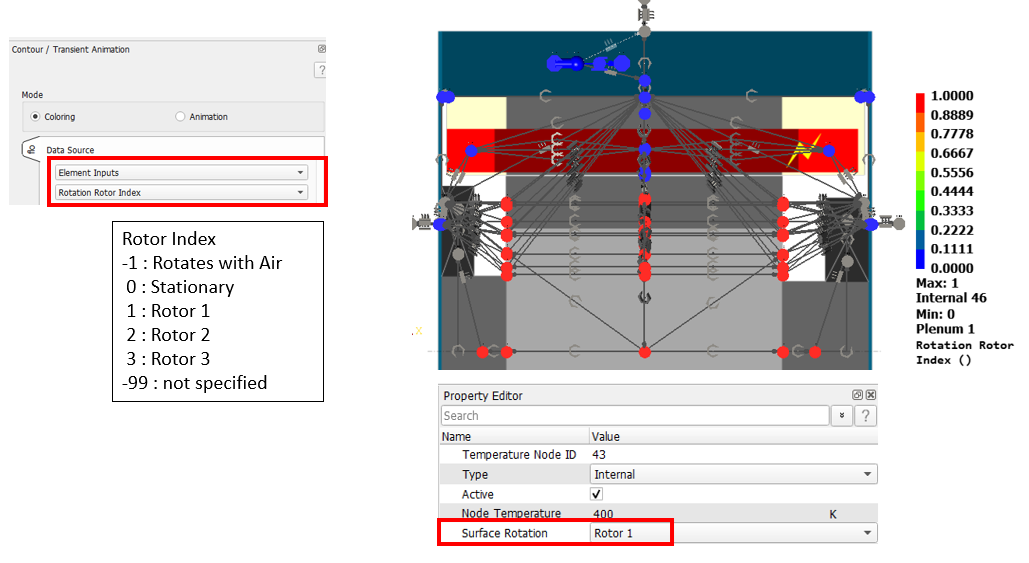

- Thermal Node and Flow Chamber Rotor Index Color Plot

- From the GUI, you can now plot color contours of the Rotor Index for thermal

nodes and flow chambers. From the color contour panel, use the

Rotation Rotor Index option. Use this to quickly

check model inputs.

Figure 9. Rotor Index Color Plot

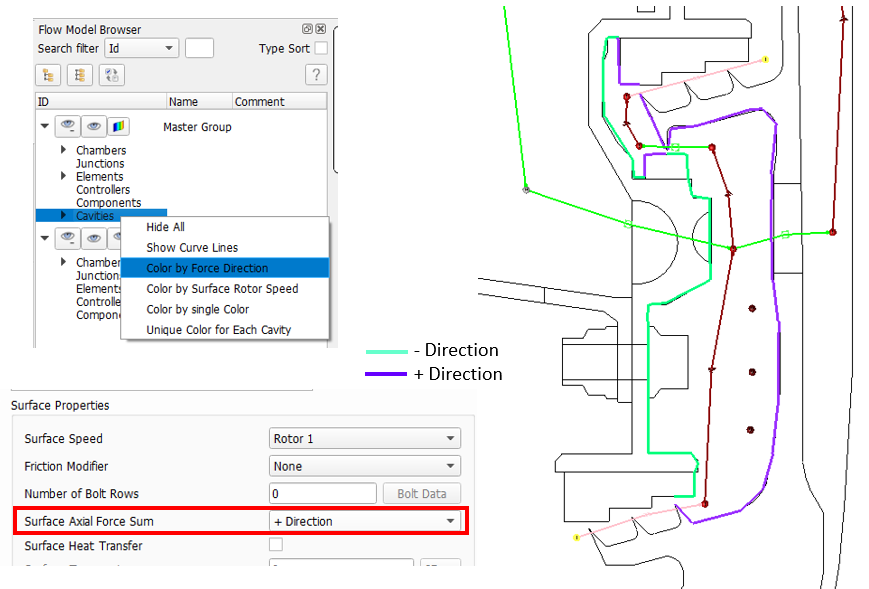

- Color Cavity Surface by Force Direction

- From the GUI, you can now color the cavity surface lines by the force

direction. Use this to quickly check the surface axial force direction

input.

Figure 10. Color Cavity Surface by Axial Force Direction

- Advanced and Incompressible Tube - New Inlet Head Loss Options

- The advanced and incompressible tube elements now have head loss options for

abrupt transition, rotating annulus, and rotating parallel tube. You can

combine the abrupt transition loss with the rotating annulus or rotating

parallel tube.

Figure 11. New Inlet Head Loss Options for the AT and IT

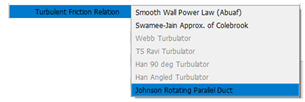

- Advanced Tube - New Friction Option

- The advanced tube has a new wall friction option for a rotating tube that is

offset and parallel to the rotation center line. It is based on a paper by

Johnson.

Figure 12. AT new Friction Option

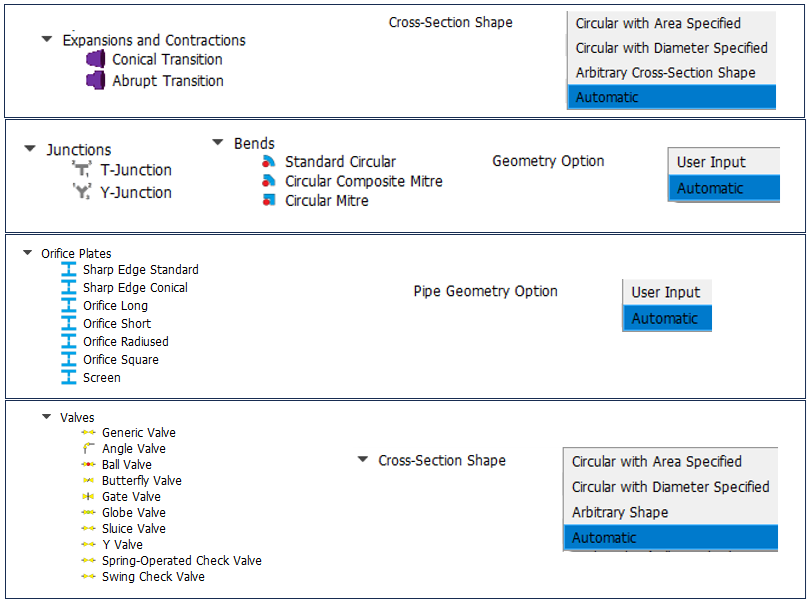

- Automatic Area Option for Several Elements

- The amount of user input has been reduced by introducing an automatic area

option for several elements. This option only works if an element is

attached to a single element upstream and downstream that has a specified

geometry (area or diameter). Two elements that use the automatic area option

cannot be attached to the same fluid chamber. The automatic option is now

the default for these elements. The areas are extracted at solver run time.

Check the *.res file for areas used for the

element.

Figure 13. New Automatic Area Retrieval Options

- Orifice Plate Element Grill K Loss

- New K loss options have been added to the Screen subtype of the orifice

plate element. These options use a K loss based on the ratio of the free (or

open) area to the pipe area. The losses are different if the grill is at the

inlet (from ambient to the pipe) or the exit (from the pipe to ambient).

Figure 14. Grill K Loss for Orifice Plate Element

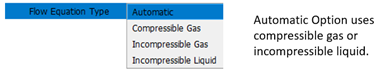

- Automatic Flow Equation (Fluid) Type for Element

- Most elements have flow equations for compressible gas and incompressible

liquids. The type of equation used can now be automatic and based on the

fluid entering the element. Compressible gas elements are used for gases

such as air, while the incompressible liquid options are used for liquids,

such as water. The benefit of the automatic option is for models that may

have phase change or if the fluid phase is not known before the run.

Elements with the automatic flow equation option include: valves,

transitions, bends, junctions, elevation, and orifice plate.Note: The orifice elements automatically use incompressible equations if a liquid is entering the element.

Figure 15.

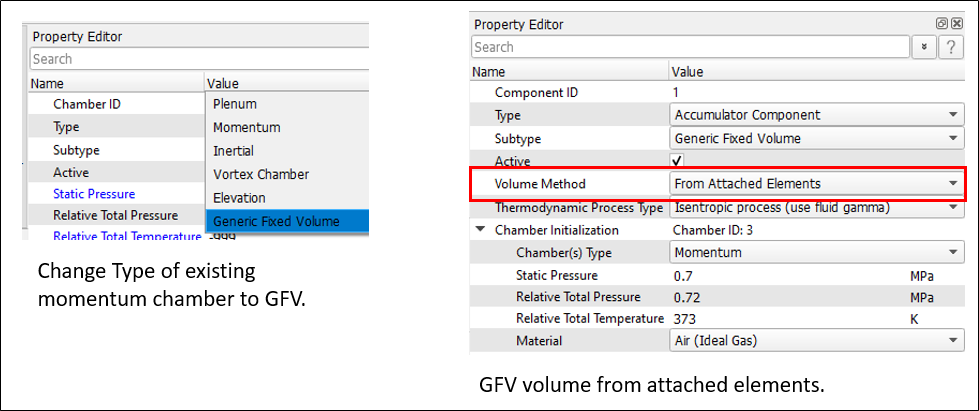

- Generic Fixed Volume (GFV) Accumulator Improvements

- Two changes have been made that make it easier to use GFV accumulators to

represent the fluid volume of piping systems for transient analysis. The

first change is the option to convert a momentum chamber to a GFV. The

automatic element creation tool creates momentum chambers. The new change

makes it easy to convert these to GFV. The second change is the option to

use the volume of the attached elements instead of a user-supplied volume.

This option uses half the volume of all elements attached to the GFV. Only

elements that have geometry information to calculate a volume are valid:

tubes, conical transitions, and bends. The *.res file

contains the volume found in the attached elements.

Figure 16. GFV Accumulator Improvements

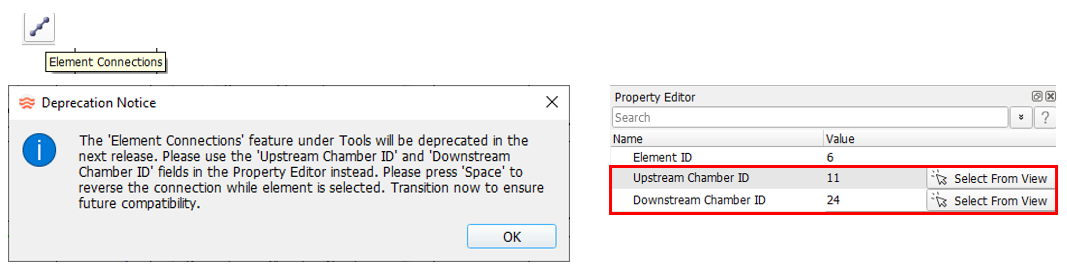

- Element and Resistor Connections

- Version 2024.1 introduced the option to change the element and resistor

connection chambers (and nodes) in the Property Editor. Now, the connecting

chambers (and nodes) can be selected from the modeling window.Note: The Element Connections tool will be deprecated in the future.

Figure 17. Element and Resistor Connection Edits

Known Issues

The following known issues will be addressed in a future release as we continuously

improve performance of the software:

- Some very large models or models using a small screen unit (like millimeters) can have text that is too small to read. The maximum size of 80 may be too small. Using a different screen unit may allow for larger text.

- Visibility of some items in dark mode will be improved in future releases.

Resolved Issues

- GUI problem with the tube element bend table always changing to four bends when edited.

- GUI crash in the Customization Manager.

- Problems with the GUI Goal Seek tool not using the number of streams when using flow rate as the target.

- GUI problem for controllers using linear relationships.

- GUI problem when copying items that are in a flow group.

- GUI problem when creating elements directly from geometry. The GUI creates less short tube elements and uses the screen unit for radius limits.

- GUI now sets the screen unit to the unit of the geometry file when reading for the first time.

- The GUI text for the vortex element flow flag is now more descriptive for the option that uses another flow element.

- GUI problem with the arrowhead sizes after multi-editing resistor connections.

- GUI problem with the defaults for drop-down lists in the Analysis Controls.

- GUI problem with units of Tube Station coordinates.

- Updated Coolprop from version 6.4.3 to version 6.6.