Silk on Pad

Check if silkscreen data are overlapped with pads.

- Silkscreen Definition: Define silkscreen layers for top and bottom layer.

- Top: Select silkscreen top layer from layer list.

- Bottom: Select silkscreen bottom layer from layer list.

- Using Gerber Layers: If users want to use silkscreen as GERBER file

in checking, define silkscreen GERBER top and bottom layer, respectively.

- Top Silk Layer: Select silkscreen GERBER top layer.

- Bottom Silk Layer: Select silkscreen GERBER bottom layer.

- Target Component Definition: Define target components.

- All Components: All components on board will be target components.

- Exclude Components: Among whole components on board, select void-checking components by selecting component groups.

- Component Group Selection: Select target components by selecting component groups.

- All Components: All components on board will be target components.

- Target Silkscreen Objects Definition

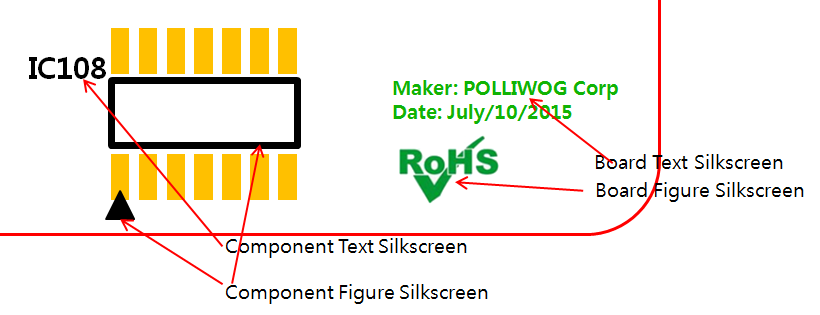

Figure 1.

- Pads Objects: Checks pads overlapping with silkscreen data in below list.

- Component Text: Check pads overlapping with component text silkscreen.

- Board Text: Check pads overlapping with board text silkscreen.

- Component Figure: Check pads overlapping with component figure silkscreen.

- Board Figure: Check pads overlapping with board figure silkscreen.

- Vias Objects: Checks vias overlapping with silkscreen data in below

list.

- Component Text: Check vias overlapping with component text silkscreen.

- Board Text: Check vias overlapping with board text silkscreen.

- Component Figure: Check vias overlapping with component figure silkscreen.

- Board Figure: Check vias overlapping with board figure silkscreen.

- Except for Silkscreen with Zero width: Exclude from the inspection if the width of the silk object is 0.

- Pads Objects: Checks pads overlapping with silkscreen data in below list.

- Checking

- Clearance between Silkscreen and Target Objects: Check the clearance

between silkscreen and selected objects. To do checking for this,

set the clearance value.

- Measure Base for Pads: Select measure base for pads.

- PAD: Measure based on the Pad shape.

- Solder Mask: Measure based on the Solder Mask shape.

- Pad/Solder Mask Overlap: Measure based on the area where the Pad and the Solder Mask of component overlap.

- Measure Base for Pads: Select measure base for pads.

- Measure Base for Vias: Select measure base for Vias.

- PAD: Measure based on the Pad shape.

- Solder Mask: Measure based on the Solder Mask shape.

- Pad/Solder Mask Overlap: Measure based on the area where the Via’s pad and the shape of the Solder Mask overlap.

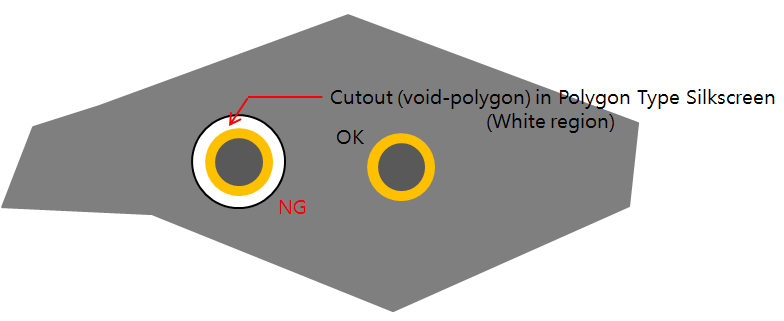

- Finding Via Cutouts for Polygon Type Silkscreen: If the silkscreen

is composed with polygon, there should not be inner void polygon.

PollEx DFM detects it.

Figure 2.

- Clearance between Silkscreen and Target Objects: Check the clearance

between silkscreen and selected objects. To do checking for this,

set the clearance value.