Dummy Pad2

Check different type of dummy pad existence in design.

- Target Layer Definition: Define target checking layers.

- Top: Use only top layer for checking.

- Bottom: Use only bottom layer for checking.

- Component Placed Layer: Use same component placed layer for dummy pad checking.

- Solder Mask Layer Definition

- Top: Recognize the specified layer as a Solder Mask of Top layer.

- Bottom: Recognize the specified layer as a Solder Mask of Bottom layer.

- Dummy Pad Component Definition: Define dummy pad checking target components.

- Dummy Pad Component Selection: Select target component from component group list.

- Soldering Direction Definition: Define the soldering direction.

- Soldering Mark Component Group: If there is soldering mark

components, select them from component group list. Using soldering

mark component, users can easily define the solder direction.

- Mark Direction: If soldering mark components are used, set the direction of soldering mark components to define the board’s soldering direction.

- Soldering Direction: If soldering mark components are not used, set the soldering direction manually.

- Soldering Mark Component Group: If there is soldering mark

components, select them from component group list. Using soldering

mark component, users can easily define the solder direction.

- Checking

- Item: Specify the item name.

- Component Group: Select target components from component group list.

- Min DD: Set the minimum distance value from component pad to dummy pads.

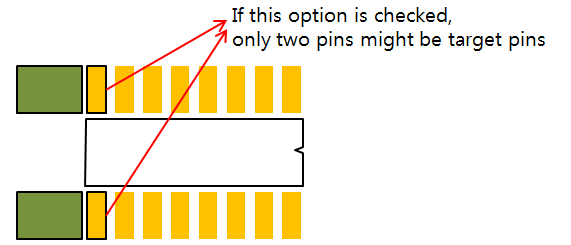

- Relative SD: Option to select target components pins after

considering soldering direction. If this option is not checked,

components’ all pins are checking target.

Figure 1.

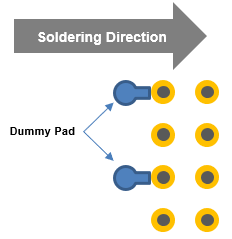

- Neighbor Dummy Pad: Pass if a neighbor pin of the target pin has a

dummy pad. Only applicable when a component is placed vertically

compared to the soldering direction.

Figure 2.

- Area Check: Option to turn on/off area checking.

- Condition: Set the condition of area checking. Setting “>” means that measuring result should be larger than given value. Otherwise it is fail.

- Area: Set the area value.

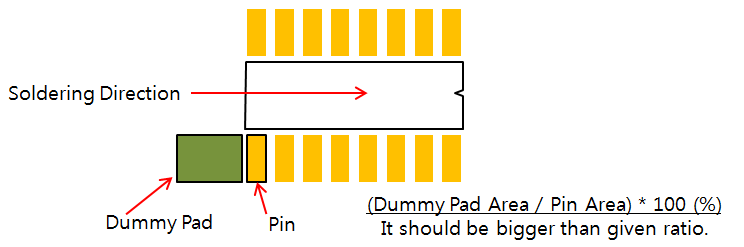

- Dummy Pad / Pin Area: Option to turn on/off “ad/Pin Area Ratio

Checking.

Figure 3.

- Min Ratio (%): Set the minimum ratio of dummy pad against pin area. It means tool small dummy pads will be fails.

- Min Length: Option to check the minimum Dummy Pad length.

- Except Same Net: Upon checking this option, if dummy pad has net property and same net name with pin, do not check.

- Reverse Check: Reverse checking option. If this option is checked, tool finds dummy pads, un-matching all above conditions.

- Width Check: Option to check if the Dummy Pad width is thicker than the PAD width.