Co-Simulating an IPM Motor with Flux 2D

Tutorial Level: Advanced Create a Twin Activate model that supplies a three-phase sine current into a Flux 2D model of an Interior Permanent Magnet motor, and co-simulate the models.

The co-simulation process includes four basic steps:

- Create a Flux model. For this tutorial, a Flux model of an IPM motor is provided for you.

- Generate the Flux coupling component required for Twin Activate to read in the Flux model data.

- Create a Twin Activate model and include the Flux block for reading in the Flux coupling component.

- Co-simulate the models from Twin Activate.

Files for This Tutorial

IPM_motor_Multiphysics_positionF2STA.FLU, IPM_motor_Multiphysics_position.F2STA, IPM_motor_Multiphysics_positionF2STA.scm

Overview of the Flux IPM Motor

The Flux model is a brushless, AC, Interior Permanent Magnet motor applicable for electric vehicles.

- Fixed part (stator) including yoke, slots, and windings

- Air gap

- Moveable rotor with embedded magnets

The IPM motor is driven with a three-phase sine current, running with kinematics type Multiphysics position. The simulated motor performances are applied for computing torque, phase current, speed and rotor position.

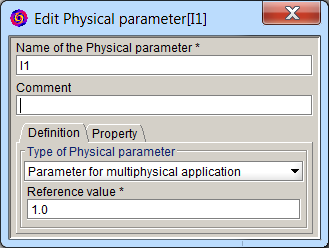

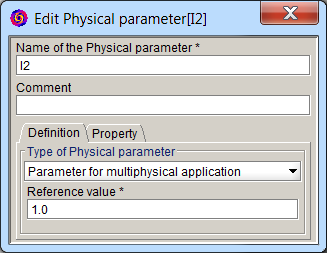

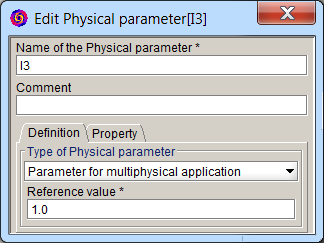

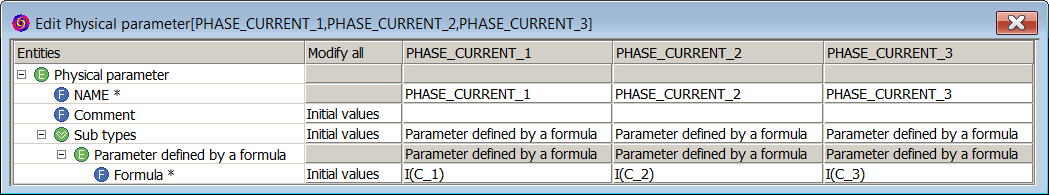

The inputs for the IPM motor are defined as multi-physical parameters and include:

- I_1: Physical quantities: μr, Bs, Br

- I_2 Electrical quantities: resistance, voltage, current

- I_3: Mechanical quantities: position, speed, electromagnetic torque

The outputs for the IPM motor are scalar I/O settings that retrieve values through the sensors, formulas (torque) and parameters (position, speed, acceleration).

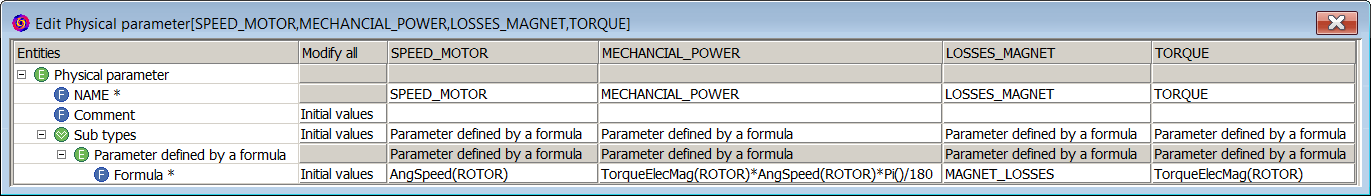

The circuit of the IPM motor is configured with a current source, coil conductor, resistor and inductance.

Generating the Coupling Component in Flux

Load the Flux model and generate the coupling component with the required inputs, outputs and parameters.

-

Launch Flux, and from your working directory, open the project,

IPM_motor_Multiphysics_positionF2STA.FLU.

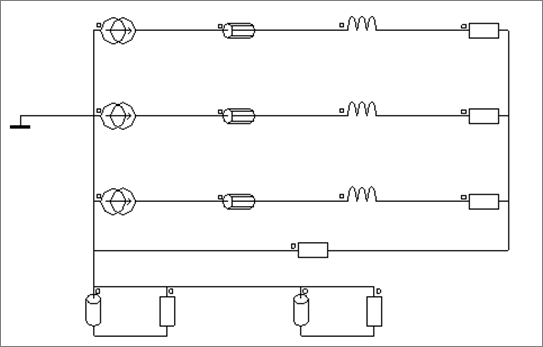

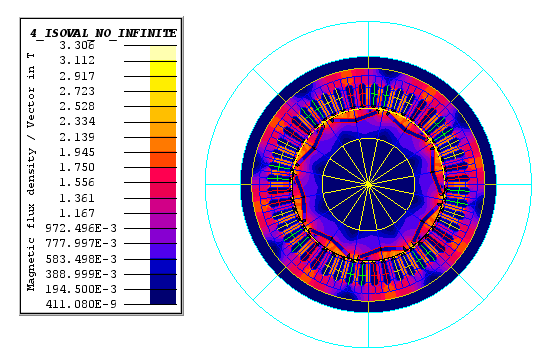

The model loads and looks something like this:

Figure 2. Cross-section view of IPM motor

- From the Flux 2D toolbar, select .

-

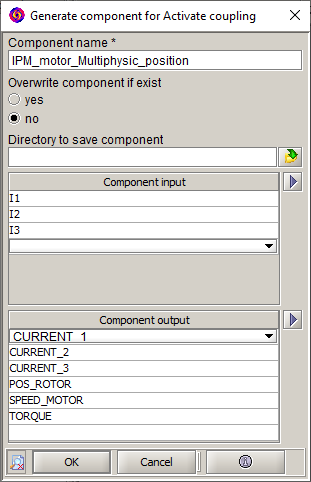

In the dialog, enter the following information for the component:

- Enter the name for the component: IPM_motor_Multiphysics_positionF2STA

- Enter the path to your working directory: <name_without_spaces>

- Select the input (geometric I/O parameters) for the component: I1, I2, I3

- Select the output: PHASE_CURRENT_1, PHASE_CURRENT_2,PHASE_CURRENT_3, TORQUE, SPEED_MOTOR and POS_ROTOR

The dialog should look something like this:

-

Click OK.

The coupling component is saved to your working directory as IPM_motor_Multiphysics_position.F2STA.

Creating the Twin Activate Model

Create a model to feed a three-phase sine current into the Flux model of the IPM motor.

-

From Twin Activate, create a new model and save it to your working directory as

IPM_motor_Multiphysics_positionF2STA.scm.

Alternatively, load the model: <installation_directory>/Tutorial Models/Flux_IPM/IPM_motor_Multiphysics_positionF2STA.scm and skip this section of the tutorial.

- From the Palette Browser, select , and drag one Flux block into your diagram.

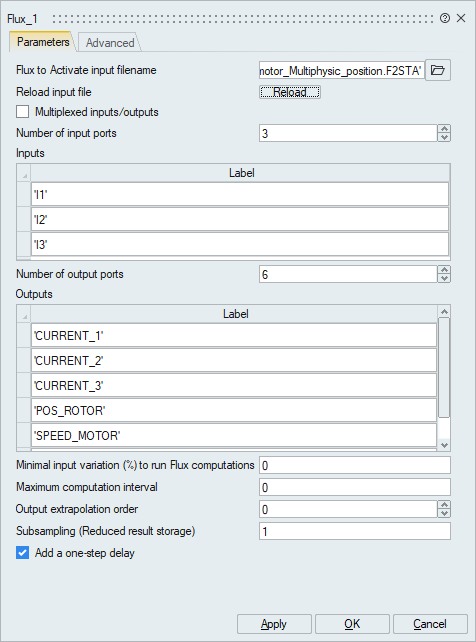

- Double-click the Flux block. In the block dialog, for Flux to Activate input filename, enter the path to the coupling component you generated from Flux: <working_directory>/ IPM_motor_Multiphysics_position.F2STA.F2STA.

-

Click OK.

The Flux block populates with the model data from the Flux coupling component.

-

For the last three fields in the Flux block dialog, enter these values:

- for Numerical memory (MB), enter 2721.

- For Character memory, enter 200.

- For Minimal input variation %, enter 10.

-

Click OK.

The Flux block dialog should look something like this:

-

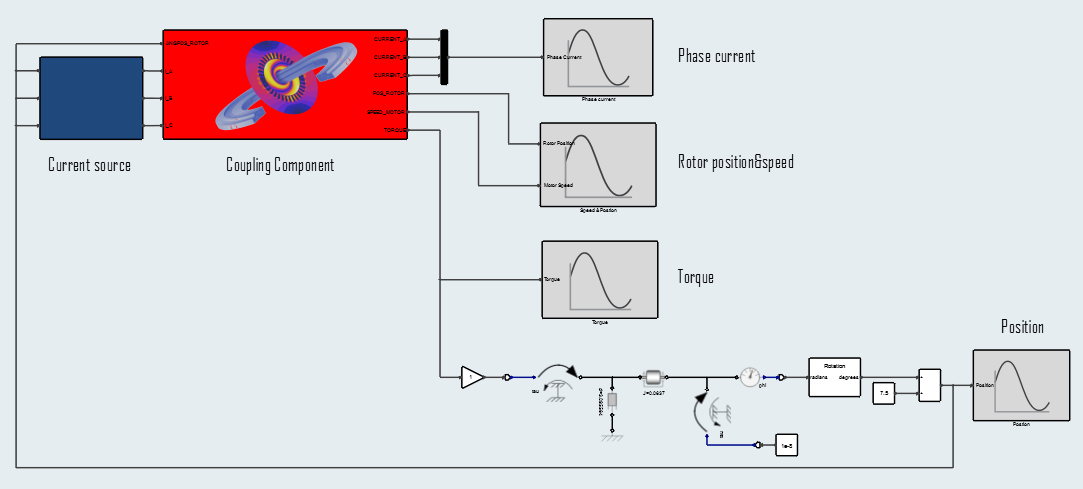

In the diagram, add three SineWaveGenerator blocks to the left of the Flux

block and define them as follows:

Define Sine Wave_1 Sine Wave_1 Sine Wave_3 Magnitude 200 200 200 Frequency (rad/s) 2 * pi * 80 2 * pi * 80 2 * pi * 80 Phase (rad) 45*pi/180 -2 * pi / 3+45*pi/180 -4 * pi / 3+45*pi/180 -

In the diagram, add four Scope blocks to the right of the Flux block, and

define them as follows:

Define Scope 1 Scope 2 Scope 3 Scope 4 Block name Currents Rotor position

Rotor speed

Torque Position Number of inputs 3 2 1 1 -

Assemble and connect the blocks as you see in the following figure, and save

the model.

Figure 3. Flux block assembled with inputs and outputs

The Twin Activate model is complete and configured to supply the Flux model of the IPM motor with three currents.

Co-Simulating the Twin Activate and Flux Models

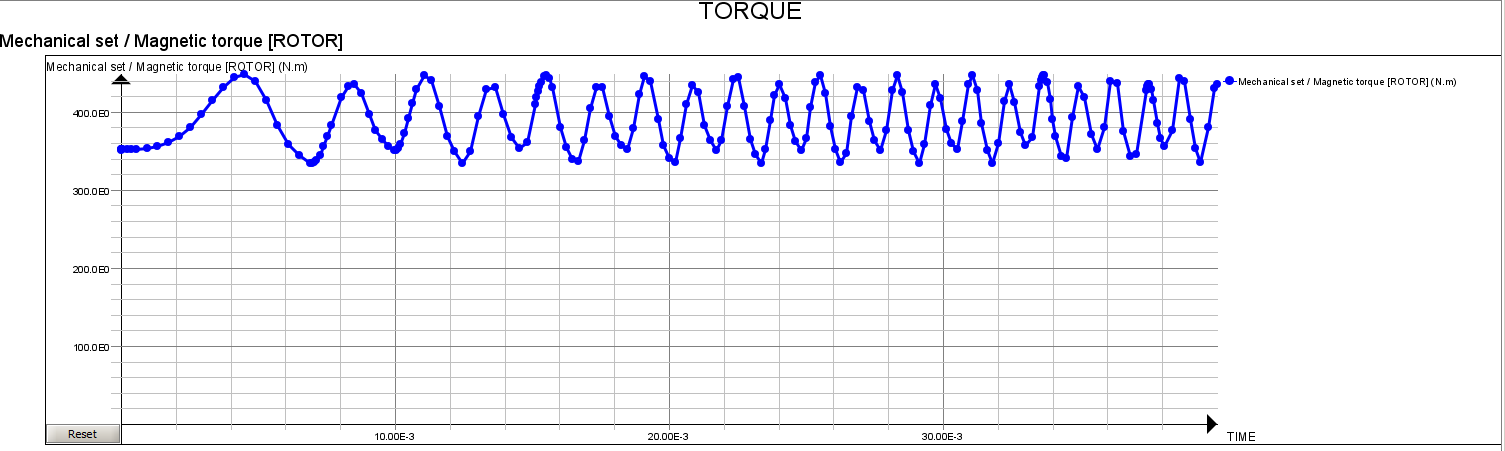

During co-simulation, the Twin Activate model supplies a three-phase sine current into the Flux model of the IPM motor. The simulation results show the performance of the IPM motor including torque and losses at constant speed.

-

On the ribbon, select Setup.

- On the dialog that appears, select the Simulation Time tab.

- For Final Time, enter .0125. Keep the defaults for the remaining fields.

- Select the Solvers tab. For the solver, select Forward Euler, and click OK. Keep the defaults for the remaining fields.

-

On the ribbon, select Run.

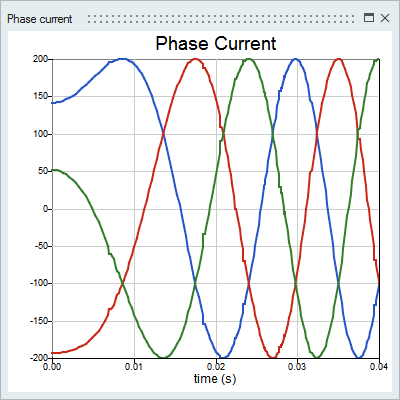

The simulation results show the currents fed into the motor and the motor performance.

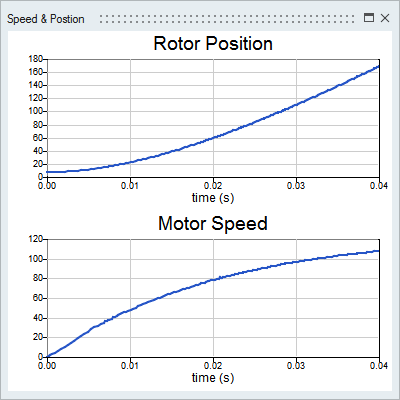

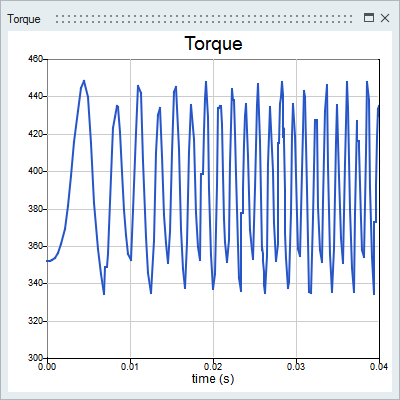

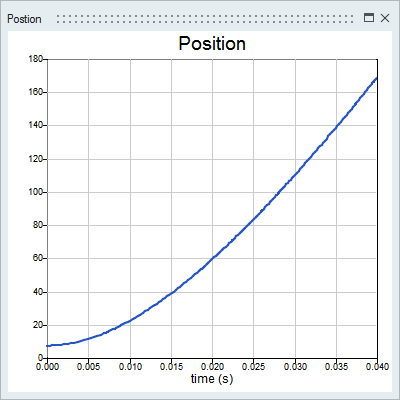

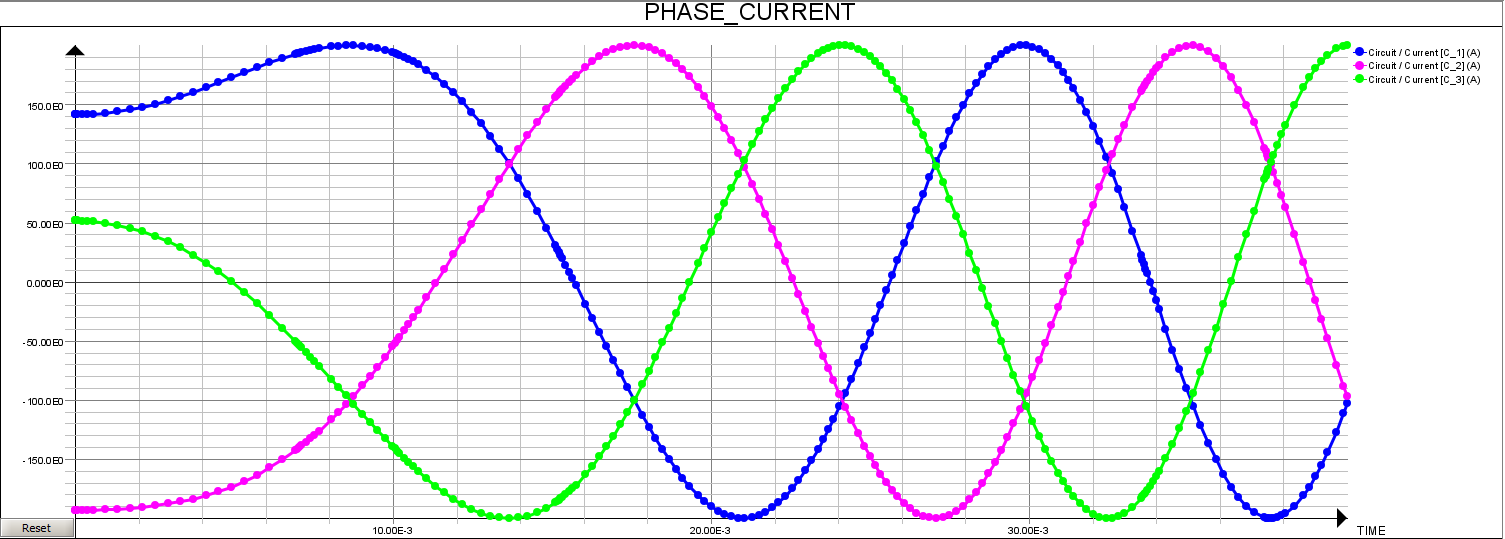

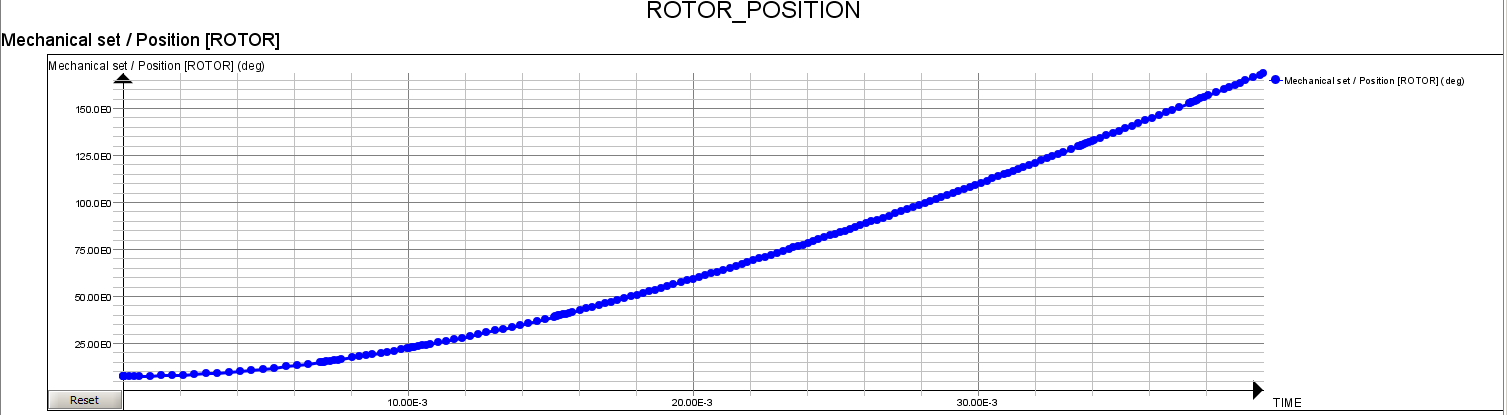

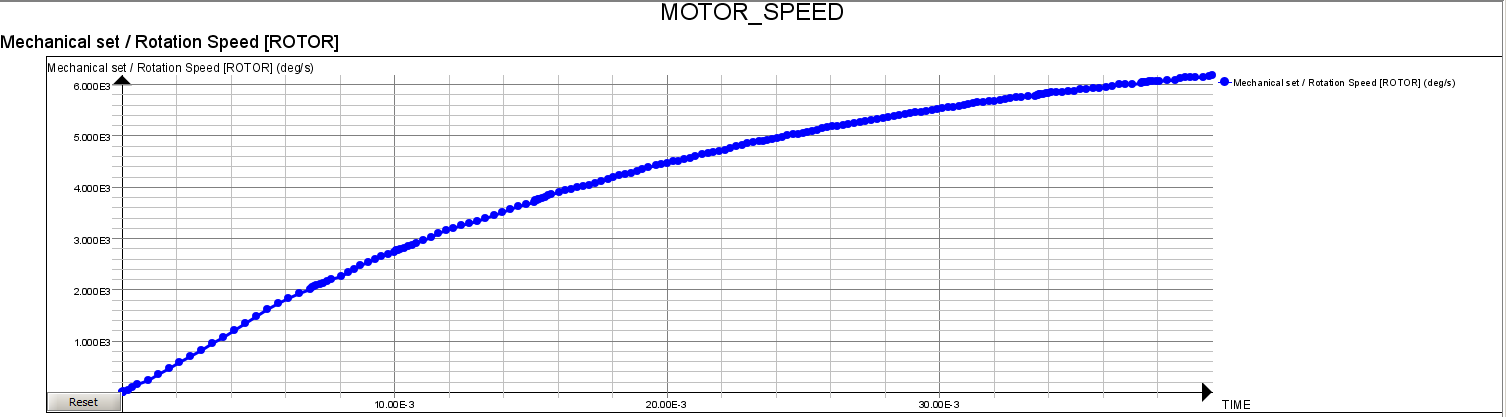

The simulation results show the currents fed into the motor and the motor performance.Figure 4. Phase current (A), rotor position (deg), motor speed (deg/s), torque (Nm) and position (deg)

Flux post-processing results show density isovalues; phase current, rotor position, motor speed, torque and position.

Figure 5. Flux density isovalues

Figure 6. Phase current (A)

Figure 7. Rotor position (deg)

Figure 8. Motor speed (deg/s)

Figure 9. Torque