/SPH/INOUT

Block Format Keyword Describes the SPH inlet/outlet conditions.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /SPH/INOUT/condition_ID | |||||||||

| condition_name | |||||||||

| Ityp | part_ID | surf_ID | Dist | node_ID1 | node_ID2 | node_ID3 | Fcut | ||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| XM | YM | ZM | |||||||

| XM1 | YM1 | ZM1 | |||||||

| XM2 | YM2 | ZM2 | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDr | Fscaler | fct_IDE | FscaleE | ||||||

| fct_IDVn | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| condition_ID | Inlet/Outlet condition

identifier. (Integer, maximum 10 digits) |

|

| condition_name | Inlet/Outlet condition

name. (Character, maximum 100 characters) |

|

| Ityp | Condition type. 22

24

(Integer) |

|

| part_ID | Part identifier is used in

order to define the SPH particles concerned by the

condition. (Integer) |

|

| surf_ID | Surface

identifier. (Integer) |

|

| Dist | Distance from the surface

for particle control. (Real) |

|

| node_ID1 | Optional ID of node 1

(Itype ≠ 1). (Integer) |

|

| node_ID2 | Optional ID of node 2

(Itype ≠ 1). (Integer) |

|

| node_ID3 | Optional ID of node 3

(Itype ≠ 1). (Integer) |

|

| Fcut | Optional Cutoff frequency

(Itype ≠ 1). Default = 0 (Real) |

|

| XM | Optional X coordinate of M

(Itype ≠ 1). (Real) |

|

| YM | Optional Y coordinate of M

(Itype ≠ 1). (Real) |

|

| ZM | Optional Z coordinate of M

(Itype ≠ 1). (Real) |

|

| XM1 | Optional X coordinate of

M1 (Itype ≠ 1). (Real) |

|

| YM1 | Optional Y coordinate of

M1 (Itype ≠ 1). (Real) |

|

| ZM1 | Optional Z coordinate of

M1 (Itype ≠ 1). (Real) |

|

| XM2 | Optional X coordinate of

M2 (Itype ≠ 1). (Real) |

|

| YM2 | Optional Y coordinate of

M2 (Itype ≠ 1). (Real) |

|

| ZM2 | Optional Z coordinate of

M2 (Itype ≠ 1). (Real) |

|

| fct_IDr | Function

fr(t)

identifier for density. (Integer) |

|

| Fscaler | Density scale

factor. Default = 0.0 (Real) |

|

| fct_IDE | Function

fE(t)

identifier for energy. (Integer) |

|

| FscaleE | Energy per volume unit

scale factor. Default = 0.0 (Real) |

|

| fct_IDVn | Function

fVn(t)

identifier for velocity in normal direction. (Integer) |

|

| fct_IDP | Function

fP(t)

identifier for pressure. (Integer) |

|

| FscaleP | Pressure scale

factor. Default = 1.0 (Real) |

|

| Characteristic length.

21 (Real) |

Comments

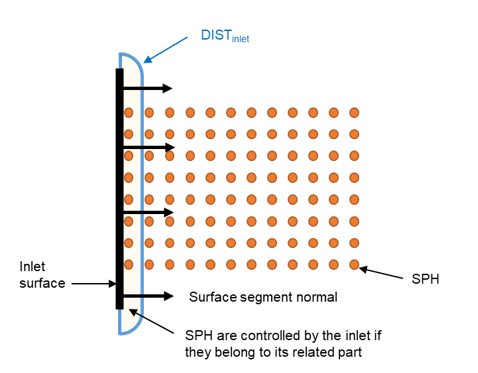

- The surface segments must be orientated so that their normal vectors point towards the interior of the domain.

- The surface must be fixed.

- In the case of an inlet condition, the condition enters particles belonging to its related part, as long as inactive particles are available for this part. The behavior of the particles belonging to the part which is associated with the condition is set with respect to the condition characteristics for all particles located on the positive side of the surface, within the distance Dist from the inlet surface.

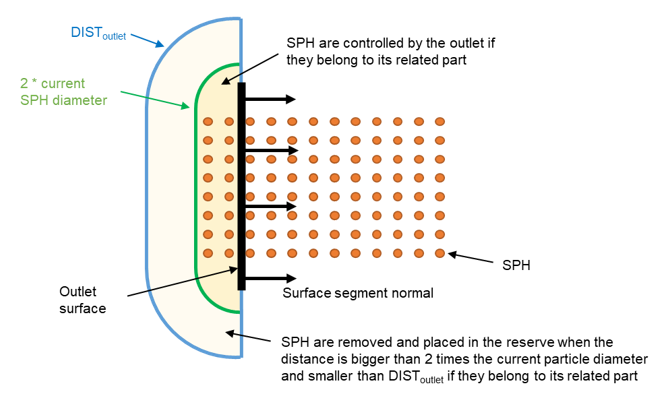

- In the case of an outlet condition, the behavior of the particles belonging to the part associated with the condition is set with respect to the condition characteristics for all particles located on the negative side of the surface, within the distance Dist from the outlet surface. Such a particle is deactivated if it does not interact with any non-outgoing particle.

- A particle deactivated by an outlet condition can be re-used by an inlet condition acting on the same part for incoming.

- If using outlets, order = -1 is recommended in the relative SPH property.

- In the case of an outlet, the

initial mesh must be created at a distance of up to 2h from the outlet surface

(where h is the smoothing length in the relative property).In the case of inlet or outlet, the distance must be large enough, in order to control incoming or outgoing particles within at least a distance of 2h.

Figure 1. Inlet Conditions Organization Overview Figure 2. Outlet Conditions Organization Overview

Figure 2. Outlet Conditions Organization Overview - The domains defined by two inlet/outlet surfaces and distances must not overlap.

- It is recommended to initially define and control the particles at both inlets and outlets to more than twice the particle smoothing length.

- The inlet/outlet conditions option is allowed for the SPMD parallel version. However, parallel arithmetic (the same numerical results are obtained regardless of the number of processors) is not guaranteed for inlet conditions.

- Each incoming particle belonging to

the part related to the condition receives the same mass

mp (defined in the

geometric property attached to the part).A particle belonging to this part is entered in the center of a surface segment at each time t such that:

(1) Where,- Si

- Area of the segment

- and

- The density and velocity of the incoming matier (Lines 2 and 3)

- tlast

- Time at last incoming through this segment

It is recommended to use a regular surface mesh.

- If inactive particles belonging to this part are not available for incoming, the program stops and you should provide a larger set of inactive particles for this part.

- If a particle belonging to the part related to the condition is located on the positive side of the surface within the Dist, its velocity is set with respect to the data specified in Line 5.

- If

fct_IDr =

0, the density of the incoming particles is set to:

(2) otherwise,(3) - If

fct_IDE =

0, the energy per volume unit of the incoming particles is

set to

,otherwise,

(4) - If a particle belonging to the part which is related to the condition is located on the negative side of the surface within the Dist, its internal pressure is set with respect to the data specified in Line 6.

- If the particle does not interact with any non-outgoing particle, the particle is deactivated.

- If

fct_IDP =

0, the internal pressure of the outgoing particles is set

to the internal pressure of the closest particle is located above the outlet

surface, otherwise it is set to

(5) - If a particle belonging to the part

related to the condition is located on the negative side of the surface within

the Dist, its internal pressure is set with respect to the equation:

(6) - If

fct_IDP =

0, the pressure in the far field

is set to

FscaleP,

otherwise it is set to FscaleP fP(t).

-

is the characteristic length, which allows to

compute cutoff frequency

as:

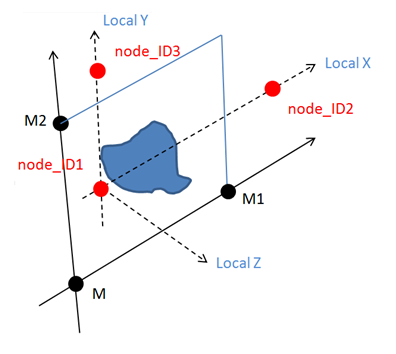

(7) - If Itype =

2, 3 or 4, the surface

can be defined by a meshed surface (surf_ID > 0), by 3 nodes (node_ID1 > 0, node_ID2 > 0 and node_ID3 > 0) or by the

coordinates of 3 nodes (M, M1 and M2).

Figure 3. - If Itype = 2, 3 or 4 and if the surface is defined by 3 coordinates, then the surface will be fixed. If the surface is defined by a surface ID or by 3 nodes, the surface will move according to the displacement of the shell elements or nodes.

- If Itype = 2, 3 or 4, a computation of the total mass crossing the surface is automatically performed and can be plotted using /TH/SPH_FLOW.