/MAT/LAW169 (ARUP_ADHESIVE)

Block Format Keyword This is an elastoplastic connection material law with coupled damage and failure. It can be used to model adhesives.

The yield and failure surfaces are described through a power law combination of normal and shear stresses. This material is applicable only to solid hexahedron elements (/BRICK) and connection property (/PROP/TYPE43 (CONNECT)).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW169/mat_ID/unit_ID or /MAT/ARUP_ADHESIVE/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | SHT_SL | TENMAX | GCTEN | ||||||

| SHRMAX | GCSHR | PWRT | PWRS | SHRP | |||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young’s (stiffness) modulus per

unit length in tension. 1 (Real) |

|

| Poisson ratio. Default = 0.0 (Real) |

||

| SHT_SL | Slope of yield surface at zero

normal stress. 3 Default = 0.0 (Real) |

|

| TENMAX | Maximum stress in normal

direction. Default = 120 (Real) |

|

| GCTEN | Energy per unit area to fail in

normal direction. 5

6 Default = 120 (Real) |

|

| SHRMAX | Maximum stress in shear

direction. Default = 120 (Real) |

|

| GCSHR | Energy per unit area to fail in

shear direction. 5

6

Default = 120 (Real) |

|

| PWRT | Power law exponent for normal

direction. Default = 2 (Integer) |

|

| PWRS | Power law exponent for shear

direction. Default = 2 (Integer) |

|

| SHRP | Shear plateau ratio. Default = 0.0 (Real) |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW169/1/1

ARUP MATERIAL

# RHO_I

7.8E-6

# E PR SHT_SL TENMAX GCTEN

1.89 0.3 2 1.6 2.0

# SHRMAX GCSHR PWRT PWRS SHRP

0.8 1.2 2 2 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The Young's

modulus is defined per displacement in order to be independent from the

initial height of the solid element.

For example, E=210000 MPa/mm means that the normal stress increases by 210000 MPa for each 1 mm of displacement until the yield stress limit or the failure limit are reached.

- The shear stiffness is computed using the Young's modulus and

Poisson ratio.

- The yield and

failure surfaces are described by a power law using the normal and shear

stresses.

Where,

- The plasticity model is not volume conserving. The plasticity only occurs in shear.

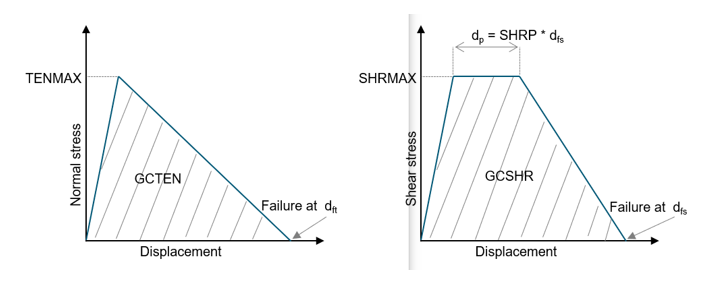

- The two

parameters GCTEN and GCSHR are

respectively the areas under the curves of stress versus displacement for

pure tension and pure shear.

Figure 1. Stress- displacement curves for pure tension and pure shear

- The failure

displacement limits are defined with:

- In pure tension

- In pure shear

Element is deleted when one failure limit is reached.

Energy per unit area to fail will be updated in the Starter to respect the following conditions. - In pure tension

- All nodes of the solid elements must be connected to other shells or solid elements, secondary nodes of rigid body (/RBODY) or secondary nodes of tied interface (/INTER/TYPE2).