OS-E: 3015 Rectangular Pressure Vessel

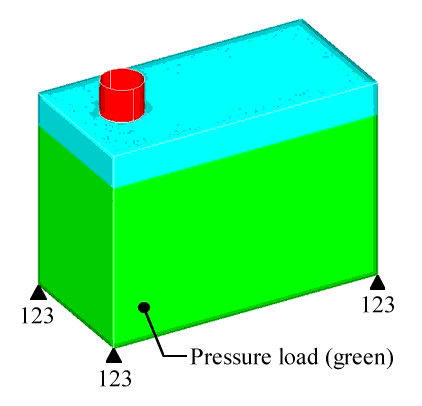

This example involves a rectangular, thin-walled container used for storing fluid. The objective is to minimize the outward bulging of the sides of the container caused by the pressure of its contents. Additionally, the maximum outward displacement of the side panels must be below a given value.

Model Files

Model Description

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPG | 1 | PSHELL | 1 | ||||||

| + | 15.0 | 60.0 | NO | 4.5 | NORM | NONE | |||

| PATRN | 10 | 7229 | 7209 |

The minimum bead width is set at 15.0mm, which is roughly the size of three elements. The draw angle is set at 60 degrees, and the draw depth is set at 7.5mm. The shape variable draw vectors are determined according to the element's normal direction. No buffer zone has been selected between the filling cap and the rest of the model. No grids are to be skipped. Therefore, the nodes (where the constraints are applied) are associated with shape variables and are free to move.

The third line of the DTPG card defines the pattern grouping option, in this case it is a plane of symmetry. For this model, symmetry was enforced by dividing the box in half lengthwise. The vector that defines the plane of symmetry was created pointing away from the side with the non-design filler cap to prevent the absence of design variables from being reflected to the design side.

- DESOBJ(MIN)

- 1

- DESSUB

- 101

| DRESP1 | 1 | obj | COMP | |||||

| DRESP1 | 2 | swall1 | DISP | 7 | 7332 | |||

| DRESP1 | 3 | swall2 | DISP | 7 | 9783 | |||

| DRESP1 | 4 | fwall | DISP | 7 | 9162 | |||

| DRESP1 | 5 | bwall | DISP | 7 | 8813 | |||

| DRESP1 | 6 | bottom | DISP | 7 | 11028 | |||

| DCONSTR | 101 | 2 | 10.0 | |||||

| DCONSTR | 101 | 3 | 10.0 | |||||

| DCONSTR | 101 | 4 | 1.0 | |||||

| DCONSTR | 101 | 5 | 1.0 | |||||

| DCONSTR | 101 | 6 | 5.0 |

The objective is to minimize compliance for the pressure load case, which is the same as minimizing the strain energy of the entire model. The displacement of the center point of each of the five loaded surfaces was constrained to be less than a given value.

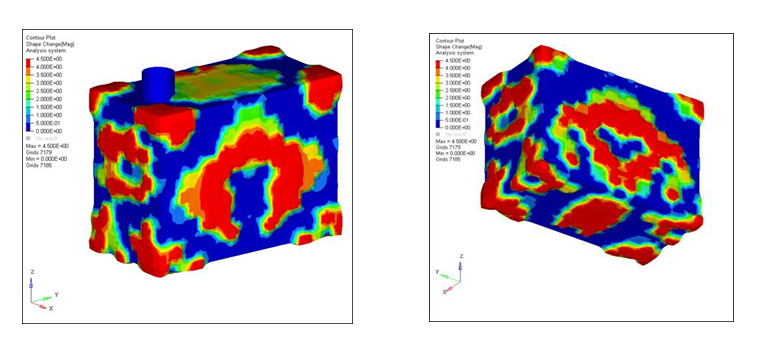

Results

All of the optimization constraints are met for the model. The red areas represent the bead reinforcements that OptiStruct created to increase the stiffness of the model. Circular or oval reinforcement beads are generated for the large side panels and the bottom panel of the box.

Circular and oval beads are very effective in stiffening the panels against a distributed or central load. This is due to the fact that bending in the central areas of the panels is occurring in two directions, both vertically and horizontally. Straight beads provide stiffness for bending in one direction, but would be vulnerable to kinking in the other. Round beads provide stiffness without kinking. Bulbous beads are created at the eight corners of the model, anchoring the sides of the box together and allowing each side of the box to gain support from the adjacent sides.