OS-T: 1930 Generate Flexible Body for use in MotionSolve

In this tutorial you will use an existing finite element model to generate a flexible body for use in MotionSolve. You will run the model in OptiStruct.

Before you begin, copy the file(s) used in this tutorial to your

working directory.

Launch HyperMesh and Set the OptiStruct User Profile

-

Launch HyperMesh.

The User Profile dialog opens.

-

Select OptiStruct and click

OK.

This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct.

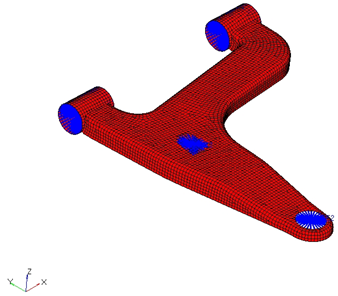

Open the Model

- Click .

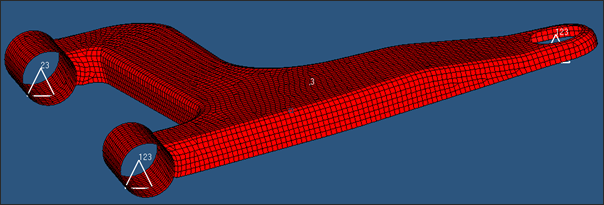

- Select the susp_sla.hm file you saved to your working directory.

-

Click Open.

The susp_sla.hm database is loaded into the current HyperMesh session, replacing any existing data.

Set Up the Model

Create Load Collectors to Conduct the Flexible Body Reduction

-

Create the ASET load collector.

This load collector will be used to define connecting degrees of freedom of the flexible body to the multi-body system.

-

Create the CMS load collector.

This load collector will be used to define the component mode synthesis method and parameters.

Modify Load Types

- From the Analysis page, click the load types panel.

- Click .

- Click return.

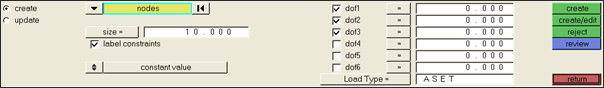

Create the ASETs

- In the Model Browser, Load Collectors folder, right-click ASET and select Make Current from the context menu.

- From the menu bar, select to open the Constraints panel.

-

Create the first constraint.

-

Create the second constraint.

- Select the degrees of freedom, dof2 and dof3.

- Using the nodes selector, select the node and the last attachment point of the control arm..

- Click create.

-

Create the third constraint.

- Select the degree of freedom, dof3.

- Using the nodes selector, select the top node in the rigid which would fasten the bottom of the shock assembly to the control arm.

- Click create.

-

Create the fourth constraint.

- Select the degrees of freedom, dof1, dof2, and dof3.

- Using the nodes selector, select the top node in the rigid on the boss to the right.

- Click create.

Create Subcase

- From the , click to open the Control Cards panel.

- Click GLOBAL_CASE_CONTROL.

- Enable CMSMETH.

- Click CMSMETH and select the CMS load collector.

- Click return to return to the Control Cards panel.

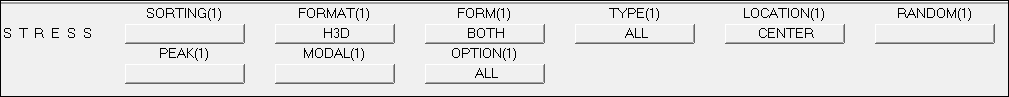

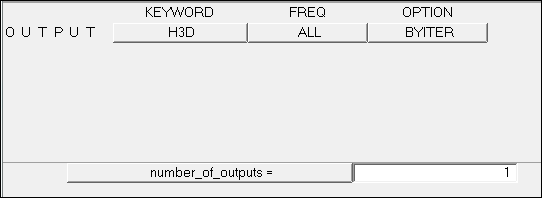

Define Output Request

- From the menu bar, click to open the Control Cards panel.

-

Define the units system for the flex body output.

The units should be defined consistent with the material properties of the material defined for this model. This way, you will not need to take care of the units of Multibody Dynamics Analysis.

-

Define the analysis type.

-

Create the output control for the component mode synthesis.

-

Create a title.

- Click TITLE.

- Enter a title for the analysis.

- Click return twice.

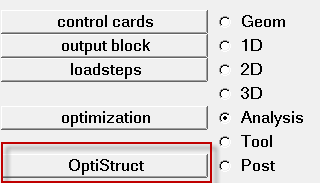

Submit the Job

-

From the Analysis page, click the OptiStruct

panel.

Figure 6. Accessing the OptiStruct Panel

- Click save as.

-

In the Save As dialog, specify location to write the

OptiStruct model file and enter

susp_sla for filename.

For OptiStruct input decks, .fem is the recommended extension.

-

Click Save.

The input file field displays the filename and location specified in the Save As dialog.

- Set the export options toggle to all.

- Set the run options toggle to analysis.

- Set the memory options toggle to memory default.

- Click OptiStruct to launch the OptiStruct job.

The default files written to the directory are:

- susp_sla.html

- HTML report of the analysis, providing a summary of the problem formulation and the analysis results.

- susp_sla.out

- OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

- susp_sla.h3d

- HyperView binary results file.

- susp_sla.res

- HyperMesh binary results file.

- susp_sla.stat

- Summary, providing CPU information for each step during analysis process.