Phase 2: Design Fine Tuning (Size Optimization)

In the second design phase, a size optimization is performed to fine tune the thicknesses of the optimized ply bundles from Phase 1: Reference Design Synthesis (Free-Size Optimization). To ensure that the optimization design meets the design requirements, additional performance criteria on natural frequencies and composite strains are incorporated into the problem formulation. A normal modes analysis load case is added to calculate the natural frequencies of the fairing under assembled conditions. The optimization setup is also modified to factor in these additional performance targets, among others.

- Design Variables

- Ply thicknesses, which have been defined in the size input deck from Phase 1: Reference Design Synthesis (Free-Size Optimization).

- Objective

- Minimize the total designable volume.

- Constraints

- Natural frequencies (1st ~ 5th) > 0.02 KHz

Manufacturing constraints are preserved and transferred to the DCOMP card. A minimum manufacturable ply thickness of 0.1, defined in Phase 1: Reference Design Synthesis (Free-Size Optimization), is transferred to the PLY card. It allows for the optimal ply bundle thicknesses to be a multiple of the minimum ply thickness value, and helps in calculating the total number of plies required per fiber orientation.

Import the Model

-

Click .

An Import tab is added to your tab menu.

- For the File type, select OptiStruct.

-

Select the Files icon

.

A Select OptiStruct file browser opens.

.

A Select OptiStruct file browser opens. - Select the fairing_freesize.*.fem file you saved to your working directory.

- Click Open.

- Click Import, then click Close to close the Import tab.

Set Up the Optimization

Review Size Optimization Design Variables

- From the Analysis page, click the optimization panel.

- Click the size panel.

-

Review the size design variables.

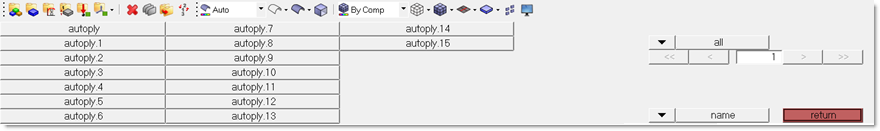

Figure 1.

- Click return to exit the size panel.

Review the Manufacturing Constraints

The manufacturing constraints were carried over to the size optimization phase automatically. They can be reviewed in the composite size panel in HyperMesh.

- From the Optimization panel, click the composite size panel.

- Select the parameters subpanel.

- Click dcomp= and select DCOMP9.

- Click edit.

-

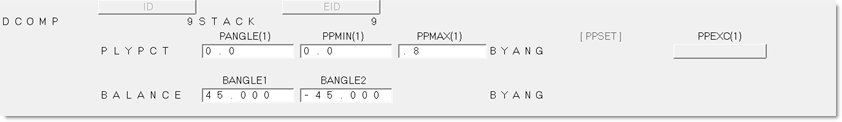

Review the DCOMP card image.

PLYPCT and BALANCE constraints (from DSIZE) are transferred to the DCOMP card. The manufacturable ply thickness constraint 0.1 in the PLYMAN continuation line (from DSIZE) is transferred to the PLY card.

Figure 2. DCOMP Entry

- Select the parameters subpanel.

- Click update.

- Click return twice to go back to the main menu.

Delete Responses in the Free-size Optimization

-

On the Collectors toolbar, click

to open the Delete panel.

to open the Delete panel.

- Set the entity selector to optiresponses.

- Click optiresponses and select wcomp and volfrac.

- Click select.

- Click delete entity.

- Click return.

Create Normal Modes Analysis

-

Create the load collector, eigrl.

-

Create the load step, norm_modes.

Create Optimization Responses

- From the Analysis page, click optimization.

- Click Responses.

-

Create the volume response, which defines the volume fraction of the design

space.

- In the responses= field, enter volume.

- Below response type, select volume.

- Set regional selection to total and no regionid.

- Click create.

-

Create the frequency response.

- In the responses= field, enter freq1.

- Below response type, select frequency.

- For Mode Number, enter 1.0.

- Click create.

A response, freq1, is defined for the frequency of the first mode extracted. - Create frequency responses for mode 2, 3, 4, and 5.

-

Create a composite strain response.

- In the response= field, enter cstrain.

- Set the response type to composite strain.

- Set the entity selector to plies, then use the plies selector to select all plies.

- Set the strain type to maj. Principle.

- Click create.

- Click return to go back to the Optimization panel.

Create Constraints

- From the Optimization panel, click the dconstraint panel.

-

Create the constraint, freq1.

- In the constraint= field, enter freq1.

- Click response= and select freq1.

- Check the box next to lower bound, then enter 0.02.

- Using the loadsteps select, select norm_modes.

- Click create.

- Repeat step 2 to create the constraints freq2, freq3, freq4, and freq5 respectively with the same lower bound of 0.02.

-

Create the constraint, cstrain.

- In the constraint= field, enter cstrain.

- Click response= and select cstrain.

- Check the box next to upper bound, then enter 0.001.

- Using the loadsteps select, select gravity and pressure.

- Click create.

- Click return to go back to the Optimization panel.

Define the Objective Function

- Click the objective panel.

- Verify that min is selected.

- Click response= and select volume.

- Click create.

- Click return twice to exit the Optimization panel.

Define the Output Request for Shuffling Deck

- From the Analysis page, click the control cards panel.

- In the Card Image dialog, click OUTPUT.

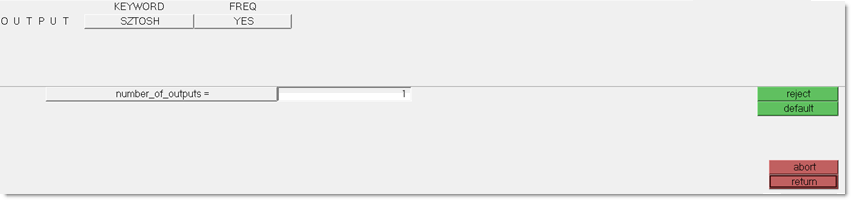

- Set KEYWORD to SZTOSH.

- Set FREQ to YES.

-

In the number_of_outputs field, enter 1.

Figure 3.

- Click return twice to go back to the Analysis page.

Run the Optimization

- From the Analysis page, click OptiStruct.

- Click save as.

-

In the Save As dialog, specify location to write the

OptiStruct model file and enter

fairing_size for filename.

For OptiStruct input decks, .fem is the recommended extension.

-

Click Save.

The input file field displays the filename and location specified in the Save As dialog.

- Set the export options toggle to all.

- Set the run options toggle to optimization.

- Set the memory options toggle to memory default.

-

Click OptiStruct to run the optimization.

The following message appears in the window at the completion of the job:

OPTIMIZATION HAS CONVERGED. FEASIBLE DESIGN (ALL CONSTRAINTS SATISFIED).

OptiStruct also reports error messages if any exist. The file fairing_size.out can be opened in a text editor to find details regarding any errors. This file is written to the same directory as the .fem file. - Click Close.

- fairing_size.out

- OptiStruct output file containing specific information on the file setup, the setup of the optimization problem, estimates for the amount of RAM and disk space required for the run, information for all optimization iterations, and compute time information. Review this file for warnings and errors that are flagged from processing the fairing_size.fem file.

- fairing_size_des.h3d

- HyperView binary results file that contain optimization results.

- fairing_size_s#.h3d

- HyperView binary results file that contains from linear static analysis, and so on.

- fairing_size_shuffling.*.fem

- A ply stacking optimization input deck. The DESVAR and DVPREL cards from the previous stage are removed, and a bare DSHUFFLE card is introduced. The * sign represents the final iteration number.

- fairing_size_shuffling.*.inc

- An ASCII include file containing ply stacking optimization data.

View the Results

- From the OptiStruct panel, click HyperView.

-

On the Results toolbar, click

to open the Contour panel.

to open the Contour panel.

- In the Results Browser, select the last iteration.

-

Click Apply.

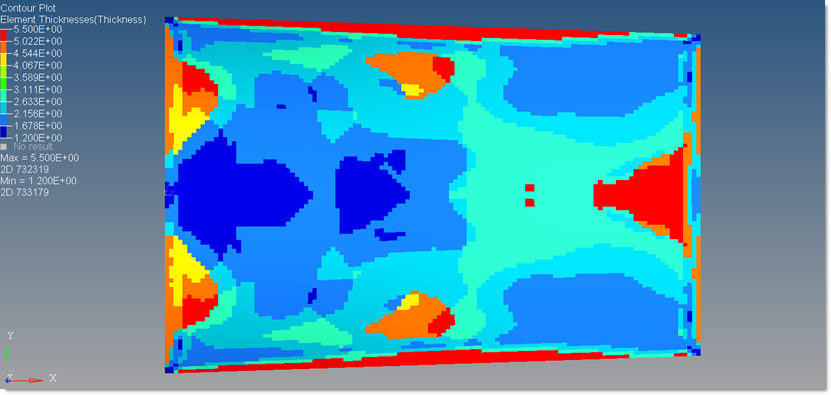

The element thickness contour plot (final iteration) after phase-2 size optimization displays.

Figure 4.

-

In the Contour panel, set the Result type to

Orientation Thicknesses (s).

The thickness contour for each ply orientation displays.

-

Set the Result type to Ply Thicknesses (s).

The thickness contour for each ply bundle displays.