Flow Between Concentric Cylinders

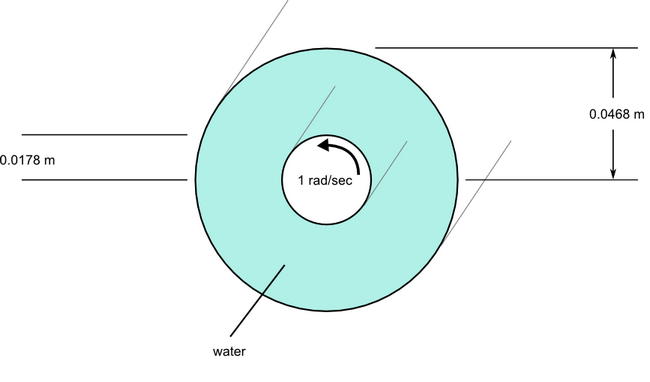

In this application, AcuSolve is used to simulate the flow of water between concentric cylinders. The outer cylinder is held stationary while the inner cylinder rotates with a constant speed. AcuSolve results are compared with analytical results as described in White (1991). The close agreement of AcuSolve results with analytical results validates the ability of AcuSolve to model cases containing thin annular gaps with flow induced by rotating walls.

Problem Description

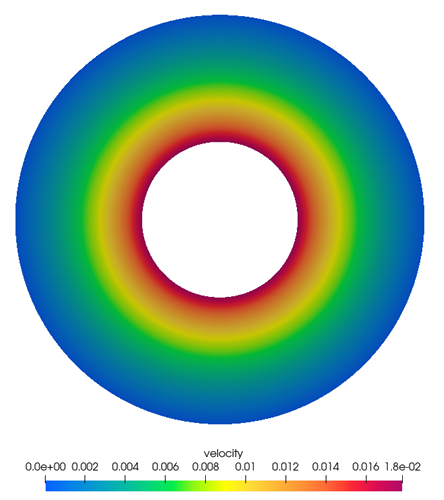

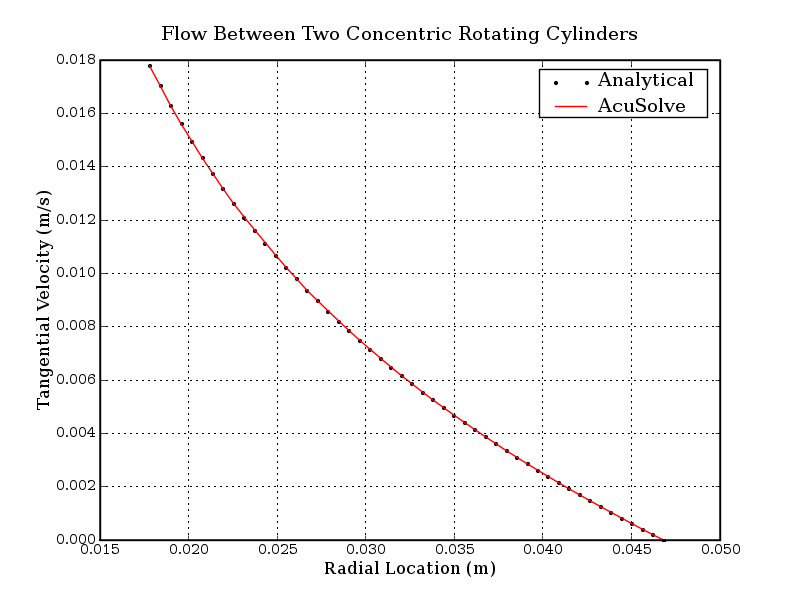

AcuSolve Results

| Distance from the center of rotating cylinder (m) | Analytical tangential velocity (m/s) | AcuSolve tangential velocity (m/s) | Percent deviation from analytical |

|---|---|---|---|

| 0.020 | 0.01514 | 0.01514 | 0.04 |

| 0.025 | 0.01059 | 0.01058 | 0.10 |

| 0.030 | 0.00727 | 0.00727 | 0.06 |

| 0.035 | 0.00466 | 0.00466 | 0.10 |

Summary

The AcuSolve solution compares well with analytical results for the flow between concentric cylinders. In this application, the velocity in the annular fluid region is driven by the viscous stresses on the rotating wall. The AcuSolve tangential velocity is within 0.1 percent of the analytical solution at all radial locations.

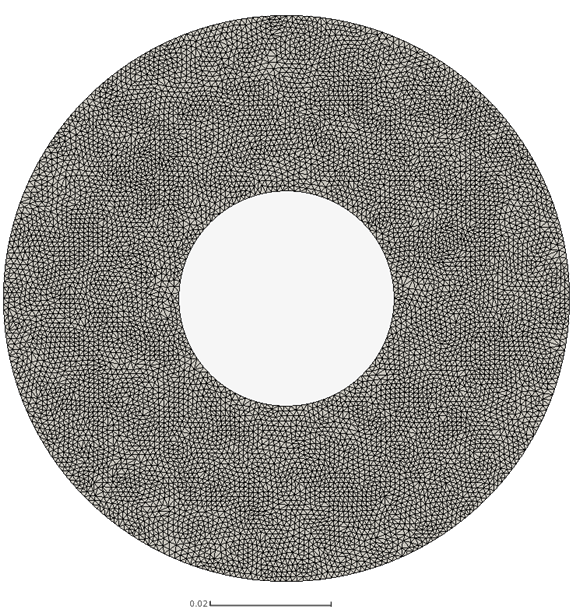

Simulation Settings for Flow Between Concentric Cylinders

HyperMesh CFD database file: <your working directory>\annulus_rotating\annulus_rotating.hm

Global

- Problem Description

- Analysis type - Steady State

- Turbulence equation - Laminar

- Auto Solution Strategy

- Relaxation Factor - 0.2

- Material Model

- Water

- Density - 1000.0 kg/m3

- Viscosity - 0.001 kg/m-sec

- Water

- Reference Frame

- Rotating_Cylinder

- Rotation center

- X-coordinate - 0.0 m

- Y-coordinate - 0.0 m

- Z-coordinate - 0.0 m

- Angular velocity

- X-component - 0.0 rad/sec

- Y-component - 0.0 rad/sec

- Z-component - -1.0 rad/sec

- Rotation center

Model

- Rotating_Cylinder

- Volumes

- Volume

- Element set

- Material model - Water

- Element set

- Volume

- Surfaces

- Boundary1

- Simple Boundary Condition

- Type - Symmetry

- Simple Boundary Condition

- Boundary2

- Simple Boundary Condition

- Type - Symmetry

- Simple Boundary Condition

- Inner

- Simple Boundary Condition

- Type - Wall

- Reference Frame - Rotating_Cylinder

- Simple Boundary Condition

- Outer

- Simple Boundary Condition

- Type - Wall

- Simple Boundary Condition

- Boundary1

- Nodes

- Fixed

- Pressure

- Type - Zero

- Pressure

- Fixed

References

F. M. White. "Viscous Fluid Flow". Section 3-2.3. McGraw-Hill Book Co., Inc. New York. 1991.