List of Flux 2022 new features

New features dealing with Environment

| New features | Description |

|---|---|

| Merge of Flux and FluxMotor setups |

The Windows installers of Flux and FluxMotor are merged into one installer. As FluxMotor is not supported on Linux, the Linux installer contains only Flux. The supervisor of Flux have direct access to FluxMotor.

The supervisor of FluxMotor have a direct access to Flux.

|

| Python API |

A Python API to drive Flux has been developed and is available in the installation directory : INSTALLATION_FOLDER\flux\Flux\Api\Python. For more information about this topic, please refer to the User Guide section dealing with the APIs. This API requires at least Python 3.0, the reference version is Python 3.5.4 and runs with Windows 64 bits and Linux. |

New features dealing with Meshing

| New features | Description |

|---|---|

| Layers Mesh Generator improvements |

The "Layers" mesh generator type allows to model a skin effect at the boundaries of volumes. In additional, since this release Flux 2022, it is possible to specify for each face if the layers mesh generator should not apply. It is useful for instance for internal faces of a volume,where the thin layer is not necessary. |

New features dealing with Physics

| New features | Description |

|---|---|

| Coil conductor regions with losses and detailed geometrical description |

This detailed description of the winding considers the proximity

and the skin effects in the Joule losses computation through

special homogenization techniques. Consequently, to set up this

model, Flux asks for a full description of the coil wires

through three templates:

This feature was already available in Flux 2D and Flux 3D Magnetic Steady State AC applications and is now available for Flux 2D Transient Magnetic application. The change application feature may be used to move from an application to another one. |

| Foil coil windings |

A foil coil is a winding obtained from a thin, rectangular, metallic sheet folded in a spiral-like shape. This kind of coil design is common in electromagnetic devices such as power transformers and reactors. The current density in a foil-wound coil fed by a time-varying source depends on skin and proximity effects. Since the foil is usually very thin and made from a material with a high electrical conductivity, the skin effect along its thickness is negligible. On the other hand, the current density in each foil turn may vary along the axial direction of the coil as a function of both position and frequency. This behavior is specific to foil coils and influences the Joule losses developed in the coil. Thus, Flux now provides a new subtype of the coil conductor region with losses and detailed geometric description that implements a homogenization technique to represent this type of coil efficiently in its 2D Steady State AC application. Using this new coil conductor region subtype spares the user from representing each turn of the foil coil with an individual solid conductor region (linked to its corresponding FE coupling component in a complicated electric circuit). While this latter approach is also legitimate and rigorous, it is usually very time consuming to set up in Flux due to the elaborate geometry and the refined mesh required. Moreover, the solving time with the new foil-wound coil conductor region subtype is significantly reduced when compared to a solid conductor approach. |

| Isotropic hysteretic Preisach models for magnetic materials in Standard User mode |

Several performance and stability issues linked to the Preisach B(H) material properties have been corrected for the Flux 2022 release. For a complete list of issues, the reader is referred to the Fixed Defects section of this release note. Consequently, this feature has been promoted to Standard mode in Flux 2022 and is now considered fully supported and qualified. This transition into Standard mode also signifies that the compatibility of Flux projects containing this feature is guaranteed from now on. Names of the Preisach B(H) material properties changed slightly. For the sake of clarity, they are now called in Flux 2022:

Furthermore, a new documentation chapter providing an overview of the Preisach-type model implemented in Flux and guidelines on how to create a material with this kind of B(H) magnetic property is now available in the user guide. |

| Material Identification Tool |

Flux 2022 provides a unified Material Identification tool based

on the Altair Compose environment to identify physical or

mathematical parameters required for the creation of a material

with the following types of B(H) magnetic properties:

And for the identification of the following a posteriori iron losses models as well: LS model and modified Bertotti model. In Flux Supervisor, at the bottom left part of the window, the button Material Identification allows the user to launch the provided tool dedicated to the parameter identification of the magnetic material models described above.  Please remark that the Material Identification module requires the Compose environment to be executed and is exclusively available on Windows OS. For more information on this feature, please refer to the User Guide documentation. |

New features dealing with Solving

| New features | Description |

|---|---|

| Free-shape optimization improvements | In the shape optimization module, available in Beta mode, it is now possible to set Physical constraints using response entities in an optimization problem. The user can also minimize or maximize the surface of a set of face while constraining other quantities. These added features are leveraging the shape optimization to a next level, where most costumer’s problem can be optimized. |

New features dealing with Postprocessing

| New features | Description |

|---|---|

| CSV Export |

The data export in CSV format allows to export global quantities in a CSV file with the following goals:

|

| Storage all curves during the solving process | Now, each curves which are displayed during the

solving process in the "Result preview" dialog box, are directly

stored and available in the Postprocessing context once the solving

process is finished. Note: If you don't want to display the

evolution of a parameter in the "result preview during the

solving", nor store its curve after solving, just rename the

parameter in question by starting it with "_".

|

New features dealing with Flux e-Machine Toolbox ( FEMT)

| New features | Description |

|---|---|

| Coupling component generation in Flux |

New motor configurations managed:

|

| FEMT improvements |

|

Updated Flux examples

As a reminder, all examples are accessible via the Flux supervisor, in the context of Open an example.

| Examples | Description |

|---|---|

| MDO 2D co-simulation |

Altair Multidisciplinary Design Optimization Platform for Electric Motors:

|

| MDO (with morphing

method) 2D co-simulation |

Altair Multidisciplinary Design Optimization Platform for Electric Motors (with morphing method):

|

| Shape Optimization of a

SRM 2D application notes |

The oml file (generated by Compose and use by OptiStruct) has been updated with a compatible Compose release. |

| Flux-SimLab: electric motor

NVH analysis 2D co-simulation |

Vibration Analysis for Electric Motors (Driven by SimLab):

|

New Flux examples

As a reminder, all examples are accessible via the Flux supervisor, in the context of Open an example.

| Examples | Description | Illustration |

|---|---|---|

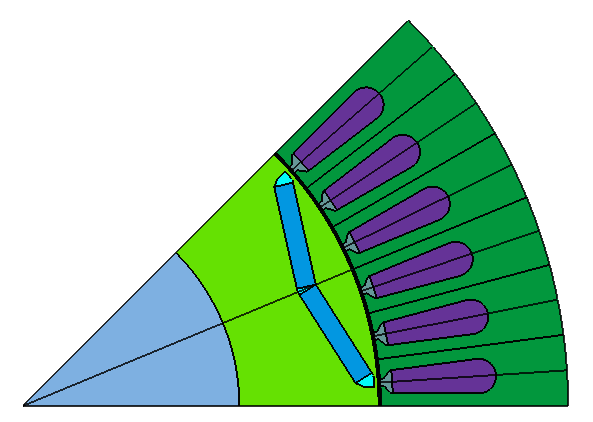

| Efficient tool set for

modeling axial flux machine 3D application note |

This case of study is devoted to the magneto-thermal modeling of an axial flux machine with one internal rotor and two external stators. Geometry, meshing, physics definition and solving will be automatically carried out by dedicated set of macros which takes as inputs the material properties and the geometrical features of the machine. |

|

New examples for Flux in SimLab

Here is the list of SimLab examples using Flux solver.

Several examples are created. These examples will be deposited in Altair Community.

| Examples | Description | Illustration |

|---|---|---|

| IPM

Brushless MT2D |

The studied device, a brushless

AC embedded permanent magnet motor presented in the figure in

the right, includes the following elements:

|

|

| SPM

Brushless MT2D |

The studied device, a brushless DC motor with surface permanent magnet, includes the following elements:

|

|

Linear Actuator MS3D |

The studied device is obtained from an import, it is a linear actuator with a coil, a mobile and a fixed part. |

|

Rear View Mirror Motor MS3D |

This tutorial illustrates a 3D model of a small permanent magnet motor, used to align the rear-view mirror of a car. The motor under study consists of four main parts: frame, permanent magnets, rotor and coils. |

|

Electric Motor of Tesla Model 3 MS3D |

The 3D studied device, the Tesla Model 3's electric motor, includes the following elements: • a fixed part (stator): yoke, slots, and windings • an air gap • a movable part (rotor) with surfaced magnets |

|

Updated macros

| Updated macros | Description |

|---|---|

| Macros

AFIR (Update) |

Now the macros devoted to Axial Flux Internal Rotor (AFIR) machines include a complete set of functionalities allowing to generate ready-to-solve thermal projects. Therefore, electromagnetic-thermal design fully automatized is available. For new macros:

A bug which avoided correct generation of AFIR machines without symmetries has been corrected. |