Keep Out Pattern

Check routing status from certain components.

If signal pattern under certain components can make electrical or mechanical problem,

you can define keep-out area from components.

- Checking for pattern existence in component area:

- Item: Specify the item name.

- Component Group: Select target components from the component group list.

- Component Boundary: Select component boundary criteria among pad, Component Overlap Checking Area (COC), silkscreen, silkscreen + pad, Measure (definition in component classification dialog), and PAD Inside (Pads’ inside area).

- Expand Component Boundary: Component boundary expanding area. To define expanding distance, set the expanding distance value.

- Contitional Layer: Option to define a area which will be recognized as a keepout area that overlapped with the keepout components.

- Target Layer: Define target layers.

- Component Placed Layer: Same with component placed layer will be target layer. Meaning, if component placed on top layer, patterns on top layer will be checked.

- Opposite Layer: Layer which is opposite the component placed layer will be target layer.

- Inner Layer: Inner layer pattern will be checked.

- All: Check all inner layers.

- From Component Placed Layer: Check the specified number of inner layers from the component placed layer.

- From Opposite Layer: Check the specified number of inner layers from the opposite side of the component placed layer.

- Target Object Definition: Define target objects for checking.

- Copper: If copper-pour exists in checking area, it will be detected.

- Trace: If routing patterns exist in checking area, it will

be detected.

- Minimum Trace Width: Define minimum trace width for checking.

- Maximum Trace Width: Define maximum trace width for checking.

- Through Via: If Through Via exists in checking area, it will be detected.

- Blind Via: If Blind Via exists in checking area, it will be detected.

- Buried Via: If Buried Via exists in checking area, it will be detected.

- Target Net

- Same Net: Patterns with the same net name with pins will be target routing patterns. In this option, different net name pattern will not be checked.

- Other Net: Patterns with different net name with pins will be target routing patterns. In this option, same net name pattern will not be checked.

- Specific Net: Option to check specific nets by using string filter.

- Except Net Name Filter: Option to exclude certain Net from checking

by using string filter.

- Import(.txt): Apply Filter Type based on the characters

entered in the .txt file.

- Apply as a prefix when (|F|) ABC is entered in the .txt file.

- Apply as a mid-string when ABC is entered in the .txt file.

- Apply as a suffix when ABC(|P|) is entered in the .txt file.

- Export(.txt): Export the characters registered in the String Item in .txt file format.

- Import(.txt): Apply Filter Type based on the characters

entered in the .txt file.

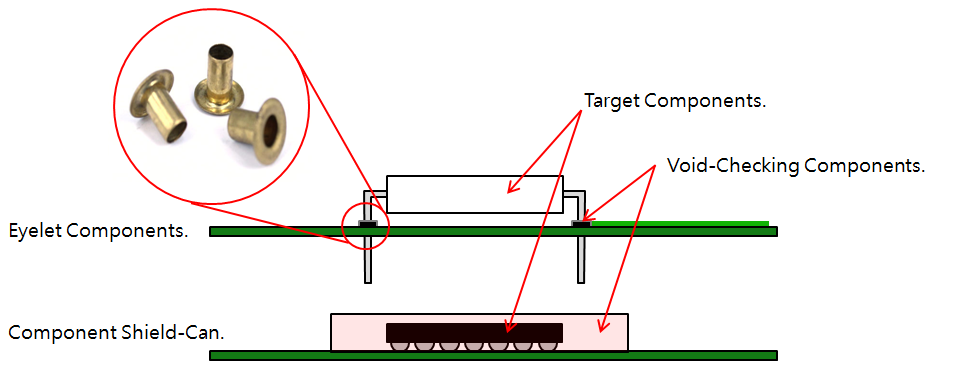

- Void-Checking Component Group: Select void-checking components with

selecting components group list. Void-Checking components would be

eyelet components or heatsink.

Figure 1.

- Distance from void-checking Comp: For patterns connected to void-checking components within given distance from void-checking components, PollEx DFM skips to check them.

- Checking for pattern existence between adjacent pins: Check patterns between

two adjacent pins.

- Item: Specify the item name.

- Comp Group: Select target components from component group list.

- Target Layer: Define target layers.

- Component Placed Layer: Same with component placed layer will be target layer. Meaning, if component placed on top layer, patterns on top layer will be checked.

- Opposite Layer: Layer which is opposite with the component placed layer will be target layer.

- Inner Layer: Inner layer pattern will be checked. Select the inner layer physical layer number.

- Same Net: Check patterns with the same net name with connected pins.

- Other Net: Check patterns with the same net name with connected pins.

- Copper: If copper-pour exists between two adjacent pins, it will be detected.

- Trace: If routing patterns exist between two adjacent pins, they will be detected.

- Via: If via exists between two adjacent pins, it will be detected.

- Checking Area reduction Ratio(%): Option to reduce the target pin and pin area by the entered ratio from checking.

- Except Net Name Filter: For void-checking routing net selection, use net name filter. Use net name filtering tool.

- Clearance between target component nets.

- Item: Specify the item name.

- Comp Group: Select target components from component group list.

- Component Boundary: Select component boundary criteria among pad,Measure (definition in component classification dialog) Component Overlap Checking Area (COC), silkscreen, silkscreen + pad, and COC+Pad.

- Target Layer: Define target layers.

- Component Placed Layer: Same with component placed layer will be target layer. Meaning, if component placed on top layer, patterns on top layer will be checked.

- Opposite Layer: Layer which is opposite with the component placed layer will be target layer.

- Inner Layer: Inner layer pattern will be checked. Select the inner layer physical layer number.

- Check Option: Specify the check option.

- Clearance: The value inputted by the user is recognized as Net Clearance and expressed in the form of "Clearance:Value" in the Check Option column.

- Set clearance value with the shortest distance between pads: Recognizes the shortest pad distance of the part to be checked as Net Clearance, expressed in the form of "Shortest distance between Pads" in the Check Option column.