SS-V:1160 槽轴中的应力集中

测试编号:VS17 求出槽轴中的应力集中。

定义

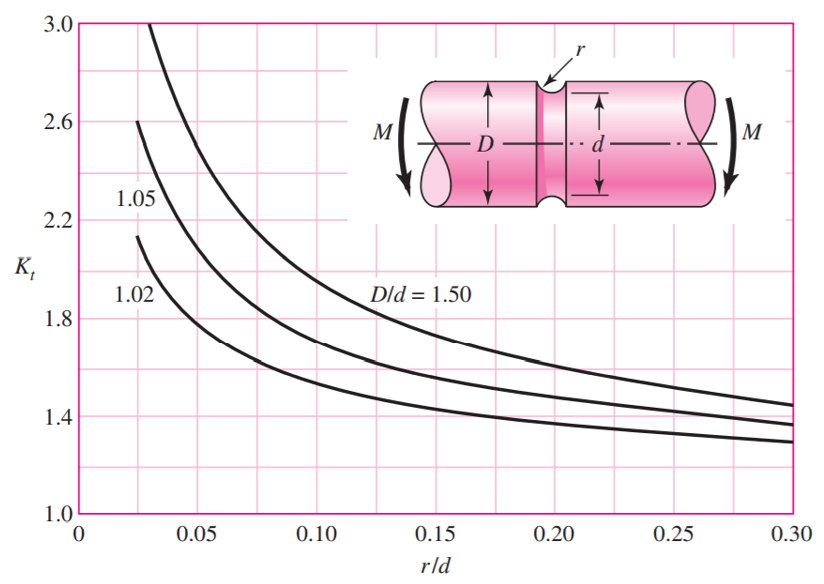

轴的一端固定。在另一端施加 98125 N-mm 的弯曲力矩。使用下面的公式计算弯曲应力为 1 MPa。

其中,

- d/2

- πd4/64

模型参数为:

- 参数

- 值

- r

- 25mm

- D

- 150mm

- d

- 100mm

- r/d

- 0.25

- D/d

- 1.5

结果

下表总结了应力结果。

| 理论1 | SimSolid | % 差异 | |

|---|---|---|---|

| 弯曲应力 [MPa] | 1.5 | 1.5 | NIL |

1 第 1030 页,Shigley’s Mechanical Engineering Design(希格利机械工程设计)第九版,Richard G Budynass 和 J. Keith Nisbett