Tutorial: Getting Started with Motion

Learn how to create connections, add a motor and spring damper force, and run a motion analysis.

In this lesson you will learn how to:

- Ground a part

- Create a rigid group

- Connect parts with joints

- Determine the direction of gravity

- Add a motor to the model

- Apply a spring-damper force

- Run a motion analysis

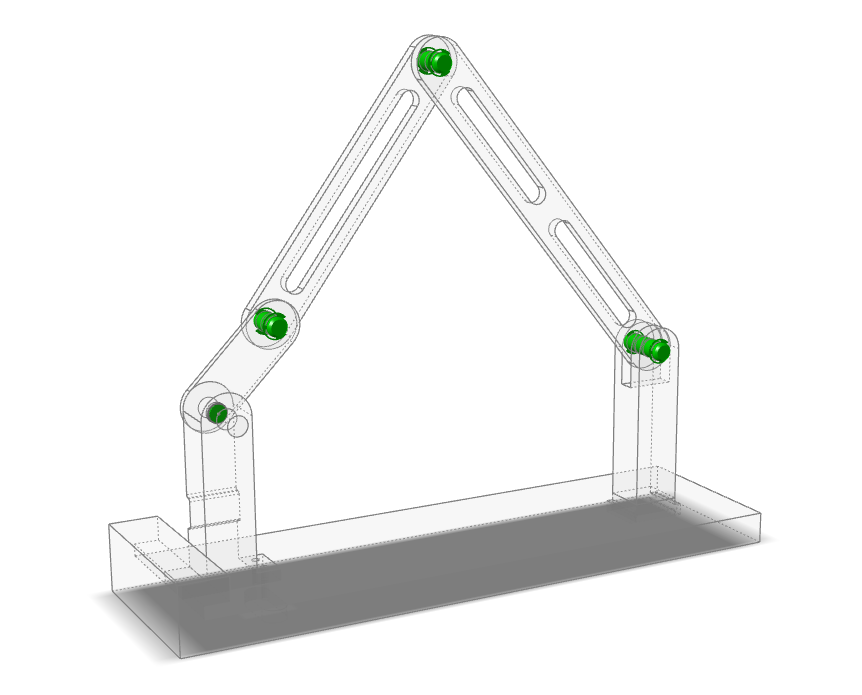

Open the CAD model

- Press F7 to open the Demo Browser.

-

Double-click the M01_FourBar.x_t file in the Motion folder

to load it in the modeling window.

- If not already visible, press F2 to open the Model Browser.

- Check that the display units are set to MKS.

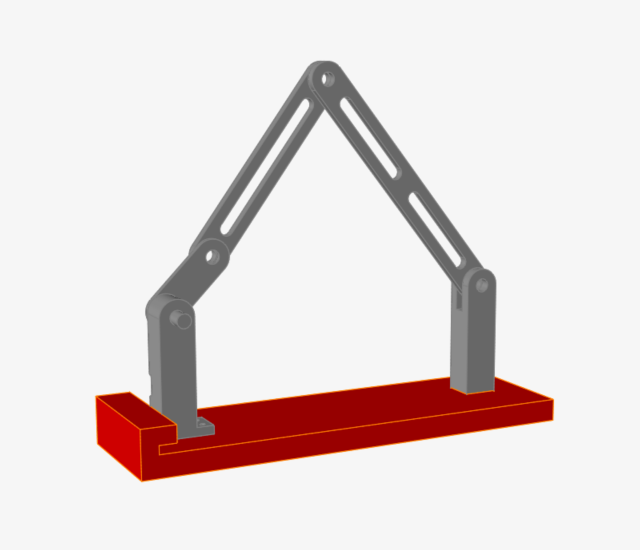

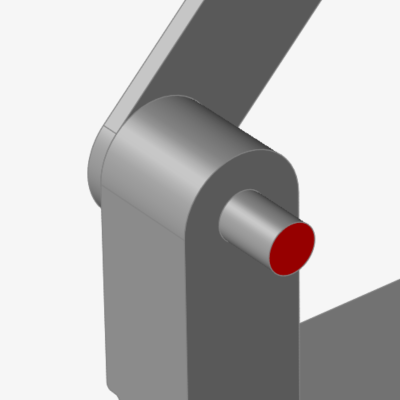

Ground a Part

-

On the Motion ribbon, select the

Ground tool from the Connections category.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

Select the Base part to ground it.

The part turns red, and the part icon in the Model Browser

changes to indicate that it is a ground part.

changes to indicate that it is a ground part.

- Right-click and mouse through the check mark to exit, or double-right-click.

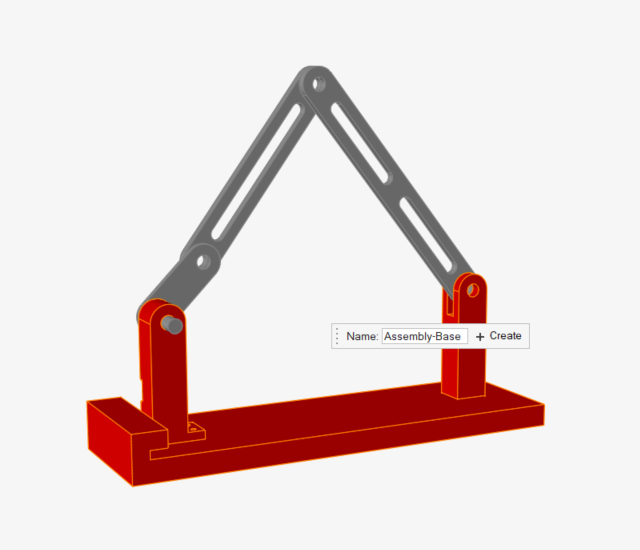

Create a Rigid Group

-

Select the Rigid Groups tool.

-

Select the Base, Mount Crank, and

Mount Clevis parts in the bottom half of the

mechanism.

The parts turn red as you select them.

-

Click the floating Create New Group icon to place the

parts you selected into a new rigid group.

- Right-click and mouse through the check mark to exit, or double-right-click.

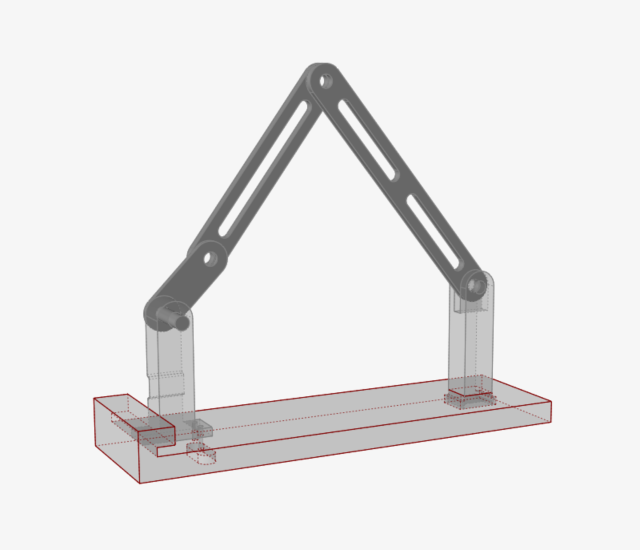

Run a Simple Motion Analysis

-

Click the Quick Run button on the Analyze Motion tool to

see the model in motion.

-

Notice that the ground parts remain stationary and some of the unconnected

parts fall down due to the effect of gravity.

Note: The Quick Run is a toggle button, so you can also use it to stop an analysis that is still running.

-

After the analysis has stopped running, the

icon appears and you are automatically placed into

review mode. Click the Review Motion Results icon or

double-right-click to exit review mode.

icon appears and you are automatically placed into

review mode. Click the Review Motion Results icon or

double-right-click to exit review mode.

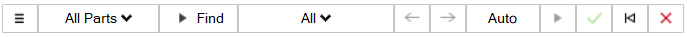

Connect Parts with Joints

-

Select the Joints tool.

- Check that the guide bar is set to the default settings (All Parts, All, Auto).

-

Click

, then the

, then the  button.

button.

Joints are created at neighboring parts in the model. The colors indicate the joint state (in this case all have been set to Active).

- Right-click and mouse through the check mark to exit, or double-right-click.

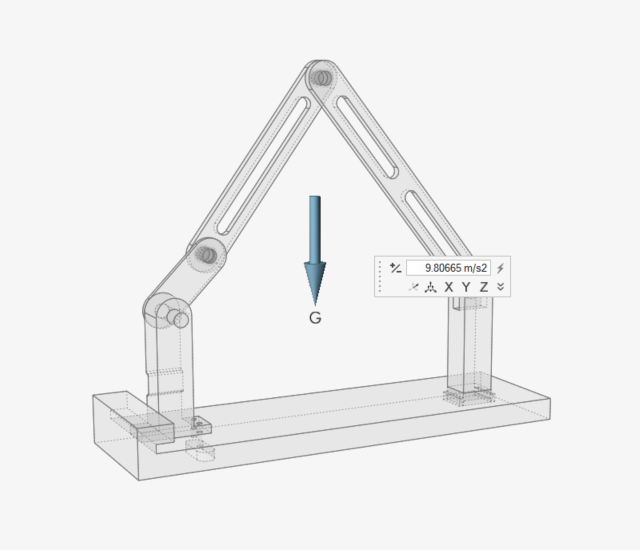

Inspect the Gravity Direction

-

Open the Gravity tool:

-

Notice that a vector is displayed which indicates the direction of

gravity.

- Right-click and mouse through the check mark to exit, or double-right-click.

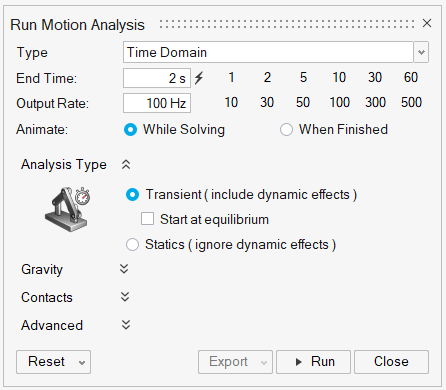

Change the Run Settings and Rerun the Analysis

-

Hover over the Analyze Motion tool, then click the

Run Settings icon to open the Run Motion Analysis

window.

- Change the Output Rate to 100 by entering the value in the field or clicking the 100 button.

-

Click Gravity and verify that it is set to

Yes.

This is the default setting for a motion analysis.

- Close the Run Motion Analysis window.

-

Click the Quick Run button on the Analyze Motion tool to

see movement of the model with the joint connections in place.

-

Click the Quick Run button again to stop the

analysis.

- Double-right-click to exit review mode.

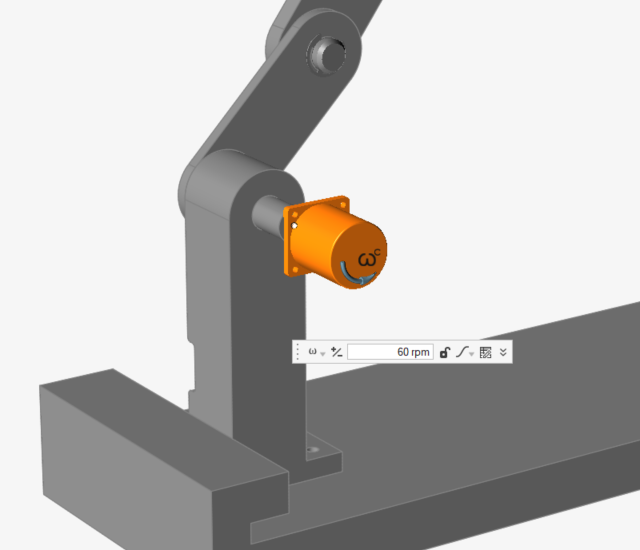

Add a Motor to Drive the Mechanism

-

Select the Motors tool.

-

Click the Cen (center) snap point of the Link Crank part

to define the shaft connection point.

The feature turns red.

-

Select the Mount Crank as the base connection.

The motor is created, and a microdialog appears with the Speed set to 60 rpm.

- Right-click and mouse through the check mark to exit, or double-right-click.

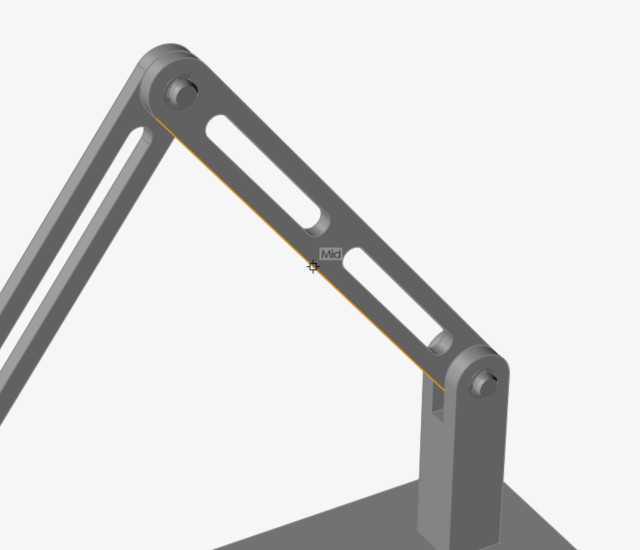

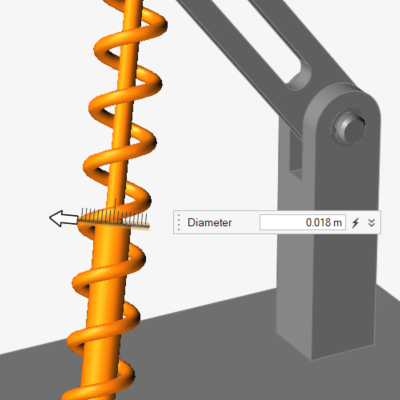

Add a Spring-Damper Force

-

Select the Coil Spring tool on the Springs icon.

-

Click the Mid (middle) snap point of the Link Dual Slot

part.

The selected feature turns red.

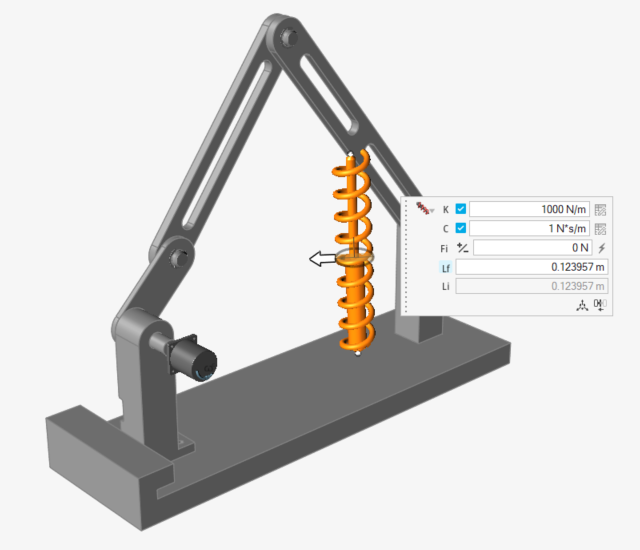

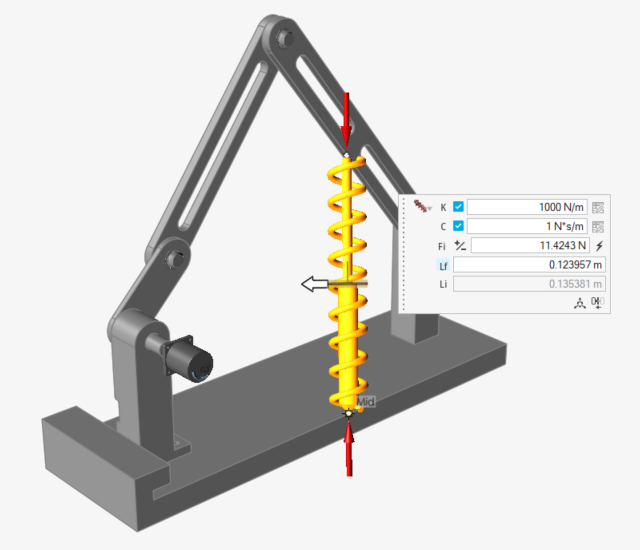

-

Select the Base part.

A coil spring appears and the microdialog shows the default settings.

-

Click and drag the end point manipulator at the bottom of the spring to

relocate it to the Mid snap point of the Base part.

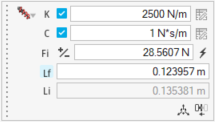

-

In the microdialog, change the K stiffness value to

2500 N/m.

-

Click and drag the white arrow manipulator to reduce the spring Diameter

slightly.

- Right-click and mouse through the check mark to exit, or double-right-click.

Change the Run Settings and Rerun the Analysis

-

Click the Run Settings icon.

-

Change the End Time to 2 s by entering the value in the

field or clicking the 2 button.

- Close the window.

-

Click the Quick Run button to see movement of the model

with motor and coil spring in place.

- After two seconds, the run will complete and you will automatically be placed into the Review Motion Results tool.

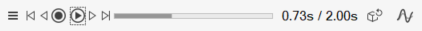

- Optional: Click the Play button on the animation toolbar to review the results.

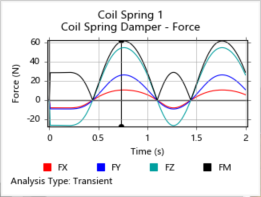

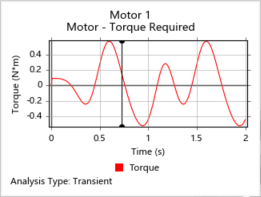

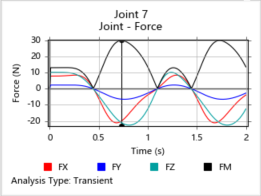

Review the Motion Analysis Results

-

Change the Time on the animation toolbar to

0.73 s by dragging the slider bar.

-

Select Coil Spring 1 in the modeling window to see a

plot of the spring forces.

-

Select Motor 1 to see a plot of the motor's

output.

-

Click on the pin connecting the Link Single Slot to the Link Dual Slot to view

a plot for the pin.

Note: Right-click on the plot to view other components that can be plotted. - Right-click and mouse through the check mark to exit, or double-right-click.