Uniform Pressure Run

A uniform pressure run should be performed to make sure that gas dynamic data, injector input, fabric materials, and contacts give physical results.

- Replace /MONVOL/FVMBAG1 with /MONVOL/AIRBAG1 keyword

- Remove injector surface from injector definition

- Comment off injector velocity curve input

- Keep all vents as in finite volume airbag

- Comment out information lines with input for finite volume bag meshing

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MONVOL/AIRBAG1/1

SAB

# Isur

4

# Ascale_T Ascale_P Ascale_S Ascale_A Ascale_D

0 0 0 0 0

# Mat_ID Pext T_0 Iequi Ittf

5000 1.0135E-4 296

# Njet

1

#inject_ID sens_IDsurf_IDinj

# 10001 22 19

10001 22

##fct_IDvel Fscalevel

# 4 0

# Nvent

0

## Iframe

# 0

## l1 l2 l3

#

## Nb1 Nb2 Nb3grbric_ID surf_IDin Iref

# 0 0 0 21 20 0

## Igmerg Cgmerg Cnmerg Ptole

# 1 1e-04 1e-04 0

## qa qb Hmin

# 0

## Ilvout Nlayer Nfacmax Nppmax ifvani

# 0 0 0 0 1

/SURF/PART/4

AIRBAG EXTERNAL SURFACE

1 2 4 5 6 7

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----| Results of simulations should be inspected visually to check for realistic airbag deployment, absence of stuck or hanging nodes due to contact intersections, time step development, energy balance, and energy error.

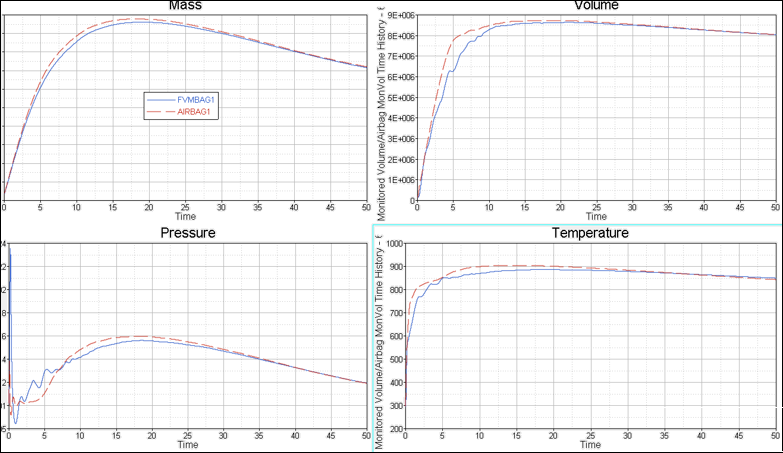

The airbag parameters, mass, volume, pressure, and temperature should be plotted and compared with the airbag volume and mass of the injected gas physical specifications.

Figure 1. Airbag parameters to control for /AIRBAG1 run

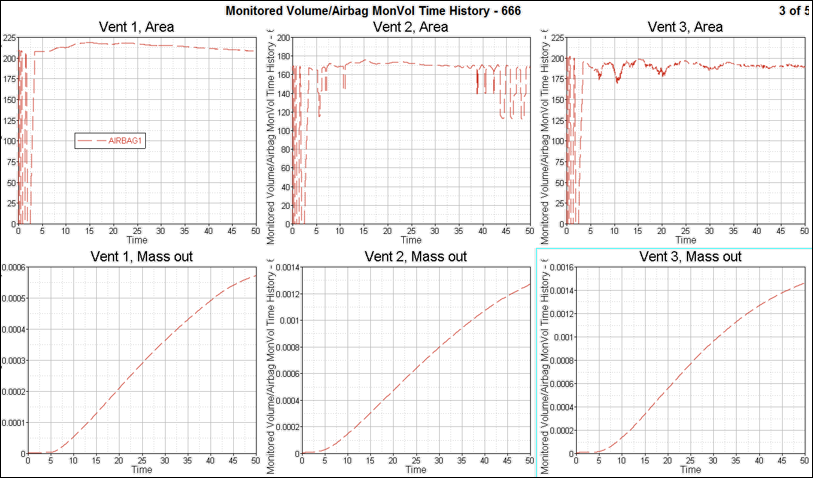

Figure 2.

This data should be used as a basic comparison to the average gas dynamic data from a /MONVOL/FVMBAG1 simulation.