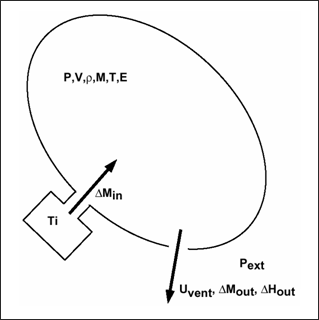

Uniform pressure is assumed inside the volume. Perfect gas law and adiabatic conditions are

assumed. Injected mass (or mass flow rate) and temperature are defined as a time

function using the injector property. A sensor can define the inflator starting

time.

The deflation of the vent hole occurs after reaching a pressure (

P

d

e

f

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG0bWaaS

baaSqaaiaadsgacaWGLbGaamOzaaqabaaaaa@3A42@

) or time (

t

d

e

f

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG0bWaaS

baaSqaaiaadsgacaWGLbGaamOzaaqabaaaaa@3A42@

) criteria.

Figure 1.

Numerical Damping

Viscosity,

μ

can be used to reduce numerical oscillations.

If

μ

=1, a critical damping (shell mass and volume stiffness) is

used. A viscous pressure,

q

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGXbaaaa@3755@

is computed as:

q

=

−

μ

A

P

A

ρ

t

V

d

V

d

t

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGXbGaey

ypa0JaeyOeI0YaaSaaaeaacqaH8oqBaeaacaWGbbaaamaakaaabaWa

aSaaaeaacaWGqbGaamyqaiabeg8aYjaadshaaeaacaWGwbaaaaWcbe

aakmaalaaabaGaamizaiaadAfaaeaacaWGKbGaamiDaaaaaaa@44EE@

if

d

V

d

t

<

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaadaWcaaqaai

aadsgacaWGwbaabaGaamizaiaadshaaaGaeyipaWJaaGimaaaa@3BD3@

q

=

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGXbGaey

ypa0JaaGimaaaa@3915@

if

d V

d t

> 0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaadaWcaaqaai

aadsgacaWGwbaabaGaamizaiaadshaaaGaeyOpa4JaaGimaaaa@3BD7@

Where,

t

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG0baaaa@3758@

Fabric thickness

ρ

Density of the fabric

A

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG0baaaa@3758@

Bag surface

The applied pressure is:

(1)

P

−

P

e

x

t

+

q

Initial Conditions

To avoid initial disequilibrium and mathematical discontinuity for zero mass or zero volume, the

following initial conditions are set at time zero (I equil I equil

P

e

x

t

=

P

i

n

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWGLbGaamiEaiaadshaaeqaaOGaeyypa0JaamiuamaaBaaa

leaacaWGPbGaamOBaiaadMgaaeqaaaaa@3EB7@

external pressure

T

0

=

T

i

n

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamivamaaBa

aaleaacaaIWaaabeaakiabg2da9iaadsfadaWgaaWcbaGaamyAaiaa

d6gacaWGPbaabeaaaaa@3C99@

initial temperature (295K by default)If the initial volume is less than

10

−

4

A

3

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaaIXaGaaG

imamaaCaaaleqabaGaeyOeI0IaaGinaaaakiaadgeadaahaaWcbeqa

amaaliaabaGaaG4maaqaaiaaikdaaaaaaaaa@3C34@

, a constant small volume is added to obtain an

initial volume:

V

i

n

i

=

10

−

4

A

3

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGwbWaaS

baaSqaaiaadMgacaWGUbGaamyAaaqabaGccqGH9aqpcaaIXaGaaGim

amaaCaaaleqabaGaeyOeI0IaaGinaaaakiaadgeadaahaaWcbeqaam

aaliaabaGaaG4maaqaaiaaikdaaaaaaaaa@411A@

Initial mass, energy and density are defined from the above values.

There is no need to define an injected mass at time zero.

Gases Definition

Initial and injected gas is defined with /MAT/GAS . Four types

of gas (MASS, MOLE, PREDEF, or CSTA) could be defined. Then the specific

capacity per unit mass at constant pressure for the gas is:

MASS type(2)

C

p

=

(

C

p

a

+

C

p

b

T

+

C

p

c

T

2

+

C

p

d

T

3

+

C

p

e

T

2

+

C

p

f

T

4

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadchaaeqaaOGaeyypa0ZaaeWaceaacaWGdbWaaSbaaSqa

aiaadchacaWGHbaabeaakiabgUcaRiaadoeadaWgaaWcbaGaamiCai

aadkgaaeqaaOGaaGjbVlaadsfacqGHRaWkcaWGdbWaaSbaaSqaaiaa

dchacaWGJbaabeaakiaaysW7caWGubWaaWbaaSqabeaacaaIYaaaaO

Gaey4kaSIaam4qamaaBaaaleaacaWGWbGaamizaaqabaGccaaMe8Ua

amivamaaCaaaleqabaGaaG4maaaakiabgUcaRmaalaaabaGaam4qam

aaBaaaleaacaWGWbGaamyzaaqabaaakeaacaWGubWaaWbaaSqabeaa

caaIYaaaaaaakiabgUcaRiaadoeadaWgaaWcbaGaamiCaiaadAgaae

qaaOGaaGjbVlaadsfadaahaaWcbeqaaiaaisdaaaaakiaawIcacaGL

Paaaaaa@5EC1@

MOLE type(3)

C

p

=

1

M

W

(

C

p

a

+

C

p

b

T

+

C

p

c

T

2

+

C

p

d

T

3

+

C

p

e

T

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadchaaeqaaOGaeyypa0ZaaSaaaeaacaaIXaaabaGaamyt

aiaadEfaaaWaaeWaceaacaWGdbWaaSbaaSqaaiaadchacaWGHbaabe

aakiabgUcaRiaadoeadaWgaaWcbaGaamiCaiaadkgaaeqaaOGaaGjb

VlaadsfacqGHRaWkcaWGdbWaaSbaaSqaaiaadchacaWGJbaabeaaki

aaysW7caWGubWaaWbaaSqabeaacaaIYaaaaOGaey4kaSIaam4qamaa

BaaaleaacaWGWbGaamizaaqabaGccaaMe8UaamivamaaCaaaleqaba

GaaG4maaaakiabgUcaRmaalaaabaGaam4qamaaBaaaleaacaWGWbGa

amyzaaqabaaakeaacaWGubWaaWbaaSqabeaacaaIYaaaaaaaaOGaay

jkaiaawMcaaaaa@5A1F@

Where,

M

W

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGnbGaam

4vaaaa@380C@

is the molecular weight of the

gas.

CSTA typeUser input

C

p

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadchaaeqaaaaa@3847@

and

C

V

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadchaaeqaaaaa@3847@

with the unit of

[

J

k

g

K

]

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaadaWadaqaam

aalaaabaGaamOsaaqaaiaadUgacaWGNbGaam4saaaaaiaawUfacaGL

Dbaaaaa@3BDB@

.

PREDEF typeAbout 14 commonly used gases (N2, O2, Air, and so on)

predefined in Radioss .

Injected gasN jet /MAT/GAS . The injector properties

(/PROP/INJECT1 or /PROP/INJECT2 )

define the injected mass curve defined

fct_ID M fct_ID T

Injected

mass curve and injection temperature can be obtained:

From the airbag manufacturer

From a tank test

sens_ID

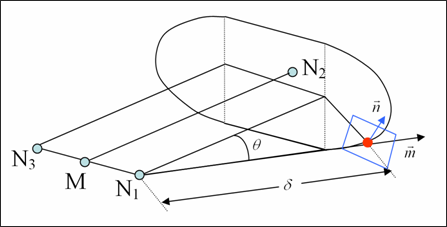

Jetting effect I jet /MONVOL/AIRBAG1 or

/MONVOL/COMMU1 If

I jet ≠ 0, the

jetting effect is modeled as an overpressure

Δ

P

j

e

t

applied to elements of the

bag.

(4)

Δ

P

j

e

t

=

Δ

P

(

t

)

⋅

Δ

P

(

θ

)

⋅

Δ

P

(

δ

)

⋅

max

(

n

·

m

,

0

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqqHuoarca

WGqbWaaSbaaSqaaiaadQgacaWGLbGaamiDaaqabaGccqGH9aqpcqqH

uoarciGGqbWaaeWaaeaacaWG0baacaGLOaGaayzkaaGaeyyXICTaeu

iLdqKaciiuamaabmaabaGaeqiUdehacaGLOaGaayzkaaGaeyyXICTa

euiLdqKaciiuamaabmaabaGaeqiTdqgacaGLOaGaayzkaaGaeyyXIC

TaciyBaiaacggacaGG4bWaaeWaaeaacaWHUbGaeS4JPFMaaCyBaiaa

cYcacaaIWaaacaGLOaGaayzkaaaaaa@5D4D@

Figure 2.

N1 , N2 , and N3 are defined

based on the injector geometry (refer to the Radioss Starter Input Manual

Δ

P

(

t

)

,

Δ

P

(

θ

)

,

Δ

P

(

δ

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqqHuoarci

GGqbWaaeWaaeaacaWG0baacaGLOaGaayzkaaGaaiilaiabfs5aejGa

ccfadaqadaqaaiabeI7aXbGaayjkaiaawMcaaiaacYcacqqHuoarci

GGqbWaaeWaaeaacqaH0oazaiaawIcacaGLPaaaaaa@4762@

are empirical functions provided by the user

via

f

c

t

_

I

D

P

t

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamiuaiaadsha

aeqaaaaa@3D9F@

,

f

c

t

_

I

D

P

θ

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamiuaiabeI7a

Xbqabaaaaa@3E5C@

, and

f

c

t

_

I

D

P

δ

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamiuaiabes7a

Kbqabaaaaa@3E4B@

Vent Hole Definition

N vent defines the number of vent holes used

s

u

r

f

_

I

D

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGZbGaam

yDaiaadkhacaWGMbGaai4xaiaadMeacaWGebWaaSbaaSqaaiaadAha

aeqaaaaa@3DD4@

surface identifier defining the vent hole

A vent vent area (if

s

u

r

f

_

I

D

v

=

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGZbGaam

yDaiaadkhacaWGMbGaai4xaiaadMeacaWGebWaaSbaaSqaaiaadAha

aeqaaOGaeyypa0JaaGimaaaa@3F9E@

) or a scale factor (

s

u

r

f

_

I

D

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGZbGaam

yDaiaadkhacaWGMbGaai4xaiaadMeacaWGebWaaSbaaSqaaiaadAha

aeqaaaaa@3DD4@

≠ 0)

B vent = 0 (if

s

u

r

f

_

I

D

v

=

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGZbGaam

yDaiaadkhacaWGMbGaai4xaiaadMeacaWGebWaaSbaaSqaaiaadAha

aeqaaOGaeyypa0JaaGimaaaa@3F9E@

) or a scale factor on the impacted surface (

s

u

r

f

_

I

D

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGZbGaam

yDaiaadkhacaWGMbGaai4xaiaadMeacaWGebWaaSbaaSqaaiaadAha

aeqaaaaa@3DD4@

≠ 0)

T stop stop time for venting

T start time at which leakage starts

Δ

P

d

e

f

relative vent deflation pressure

Δ

t

P

d

e

f

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqqHuoarca

WG0bGaamiuamaaBaaaleaacaWGKbGaamyzaiaadAgaaeqaaaaa@3C7D@

Time duration during which

Δ

P

>

Δ

P

d

e

f

f

c

t

_

I

D

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamODaaqabaaa

aa@3CCC@

Function identifier

f

P

(

P

−

P

e

x

t

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaciGGMbWaaS

baaSqaaiaadcfaaeqaaOWaaeWaaeaacaWGqbGaeyOeI0Iaamiuamaa

BaaaleaacaWGLbGaamiEaiaadshaaeqaaaGccaGLOaGaayzkaaaaaa@3F8C@

for Chemkin model (I form

(5)

v

e

n

t

_

h

o

l

e

s

_

s

u

r

f

a

c

e

=

A

v

e

n

t

⋅

A

n

o

n

_

i

m

p

a

c

t

e

d

⋅

f

t

(

t

)

⋅

f

P

(

P

−

P

e

x

t

)

⋅

f

A

(

A

n

o

n

_

i

m

p

a

c

t

e

d

A

0

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaqaaaaaaaaa

WdbiaadAhacaWGLbGaamOBaiaadshacaGGFbGaamiAaiaad+gacaWG

SbGaamyzaiaadohacaGGFbGaam4CaiaadwhacaWGYbGaamOzaiaadg

gacaWGJbGaamyzaiaabccacqGH9aqppaGaamyqamaaBaaaleaacaWG

2bGaamyzaiaad6gacaWG0baabeaakiabgwSixlaadgeadaWgaaWcba

GaamOBaiaad+gacaWGUbGaai4xaiaadMgacaWGTbGaamiCaiaadgga

caWGJbGaamiDaiaadwgacaWGKbaabeaakiabgwSixlGacAgadaWgaa

WcbaGaamiDaaqabaGcdaqadaqaaiaadshaaiaawIcacaGLPaaacqGH

flY1ciGGMbWaaSbaaSqaaiaadcfaaeqaaOWaaeWaaeaacaWGqbGaey

OeI0IaamiuamaaBaaaleaacaWGLbGaamiEaiaadshaaeqaaaGccaGL

OaGaayzkaaGaeyyXICTaciOzamaaBaaaleaacaWGbbaabeaakmaabm

aabaWaaSaaaeaacaWGbbWaaSbaaSqaaiaad6gacaWGVbGaamOBaiaa

c+facaWGPbGaamyBaiaadchacaWGHbGaam4yaiaadshacaWGLbGaam

izaaqabaaakeaacaWGbbWaaSbaaSqaaiaaicdaaeqaaaaaaOGaayjk

aiaawMcaaaaa@8254@

If

f

c

t

_

I

D

v

≠

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamODaaqabaGc

cqGHGjsUcaaIWaaaaa@3F57@

, the outflow velocity,

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaaleaacaWG2baaaa@375B@

is defined by Chemkin

as:

(6)

v

=

F

s

c

a

l

e

v

f

v

(

P

−

P

e

x

t

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG2bGaey

ypa0JaamOraiaadohacaWGJbGaamyyaiaadYgacaWGLbWaaSbaaSqa

aiaadAhaaeqaaOGaciOzamaaBaaaleaacaWG2baabeaakmaabmaaba

GaamiuaiabgkHiTiaadcfadaWgaaWcbaGaamyzaiaadIhacaWG0baa

beaaaOGaayjkaiaawMcaaaaa@4850@

Where,

F

s

c

a

l

e

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGgbGaam

4CaiaadogacaWGHbGaamiBaiaadwgadaWgaaWcbaGaamODaaqabaaa aa@3CF2@

is the scale factor of the function

f

c

t

_

I

D

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaam

4yaiaadshacaGGFbGaamysaiaadseadaWgaaWcbaGaamODaaqabaaa aa@3CCC@

.

and the outgoing mass is computed as:

(7)

m

˙

o u t

= ρ ⋅

A

v e n t

⋅

f

v

(

P −

P

e x t

) ⋅ F s c a l

e

v

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGTbGbai

aadaWgaaWcbaGaam4BaiaadwhacaWG0baabeaakiabg2da9iabeg8a

YjabgwSixlaadgeadaWgaaWcbaGaamODaiaadwgacaWGUbGaamiDaa

qabaGccqGHflY1ciGGMbWaaSbaaSqaaiaadAhaaeqaaOWaaeWaaeaa

caWGqbGaeyOeI0IaamiuamaaBaaaleaacaWGLbGaamiEaiaadshaae

qaaaGccaGLOaGaayzkaaGaeyyXICTaamOraiaadohacaWGJbGaamyy

aiaadYgacaWGLbWaaSbaaSqaaiaadAhaaeqaaaaa@58CE@

Or, with the conservation of enthalpy between airbag and vent hole, adiabatic

conditions and unshocked flow, it is then possible to express outgoing mass flow

through vent holes as a function of

P

e

x

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWGLbGaamiEaiaadshaaeqaaaaa@39D7@

,

ρ

,

P

v

e

n

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWG2bGaamyzaiaad6gacaWG0baabeaaaaa@3AC8@

,

u

v

e

n

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyDamaaBa

aaleaacaWG2bGaamyzaiaad6gacaWG0baabeaaaaa@3AED@

and

A

v

e

n

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqamaaBa

aaleaacaWG2bGaamyzaiaad6gacaWG0baabeaaaaa@3AB9@

.

(8)

m

˙

o u t

=

ρ

v e n t

⋅

A

v e n t

⋅ u = ρ

(

P

e x t

P

)

1

γ

⋅

A

v e n t

⋅ u

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGTbGbai

aadaWgaaWcbaGaam4BaiaadwhacaWG0baabeaakiabg2da9iabeg8a

YnaaBaaaleaacaWG2bGaamyzaiaad6gacaWG0baabeaakiabgwSixl

aadgeadaWgaaWcbaGaamODaiaadwgacaWGUbGaamiDaaqabaGccqGH

flY1caWG1bGaeyypa0JaeqyWdi3aaeWaaeaadaWcaaqaaiaadcfada

WgaaWcbaGaamyzaiaadIhacaWG0baabeaaaOqaaiaadcfaaaaacaGL

OaGaayzkaaWaaWbaaSqabeaadaWcaaqaaiaaigdaaeaacqaHZoWzaa

aaaOGaeyyXICTaamyqamaaBaaaleaacaWG2bGaamyzaiaad6gacaWG

0baabeaakiabgwSixlaadwhaaaa@61C2@

In the case of supersonic outlet flow, the vent pressure,

P

v

e

n

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWG2bGaamyzaiaad6gacaWG0baabeaaaaa@3AC8@

is equal to external pressure,

P

e

x

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWGLbGaamiEaiaadshaaeqaaaaa@39D7@

for unshocked flow. For shocked flow,

P

v

e

n

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWG2bGaamyzaiaad6gacaWG0baabeaaaaa@3AC8@

is equal to critical pressure,

P

c

r

i

t

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiuamaaBa

aaleaacaWGJbGaamOCaiaadMgacaWG0baabeaaaaa@3ABD@

and velocity,

u

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyDaaaa@36F0@

is bounded to critical sound speed:

(9)

u

2

<

2

γ + 1

c

2

=

2 γ

γ + 1

P

ρ

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWG1bWaaW

baaSqabeaacaaIYaaaaOGaeyipaWZaaSaaaeaacaaIYaaabaGaeq4S

dCMaey4kaSIaaGymaaaacaWGJbWaaWbaaSqabeaacaaIYaaaaOGaey

ypa0ZaaSaaaeaacaaIYaGaeq4SdCgabaGaeq4SdCMaey4kaSIaaGym

aaaadaWcaaqaaiaadcfaaeaacqaHbpGCaaaaaa@489D@

and

(10)

P

c

r

i

t

=

P

(

2

γ

+

1

)

γ

γ

−

1

(11)

P

v

e

n

t

=

max

(

P

c

r

i

t

,

P

e

x

t

)

The outgoing mass flow of gas

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAaaaa@36E4@

is:

(12)

m

˙

o u t

(

i

)

=

V

(

i

)

V

m

˙

o u t

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGTbGbai

aadaWgaaWcbaGaam4BaiaadwhacaWG0baabeaakmaaCaaaleqabaWa

aeWaaeaacaWGPbaacaGLOaGaayzkaaaaaOGaeyypa0ZaaSaaaeaaca

WGwbWaaWbaaSqabeaadaqadaqaaiaadMgaaiaawIcacaGLPaaaaaaa

keaacaWGwbaaaiqad2gagaGaamaaBaaaleaacaWGVbGaamyDaiaads

haaeqaaaaa@46AD@

Where,

V

(

i

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOvamaaCa

aaleqabaGaaiikaiaadMgacaGGPaaaaaaa@3945@

is the volume occupied by gas

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAaaaa@36E4@

and satisfies:

(13)

V

(

i

)

=

n

(

i

)

n

V

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGwbWaaW

baaSqabeaadaqadaqaaiaadMgaaiaawIcacaGLPaaaaaGccqGH9aqp

daWcaaqaaiaad6gadaahaaWcbeqaamaabmaabaGaamyAaaGaayjkai

aawMcaaaaaaOqaaiaad6gaaaGaamOvaaaa@406D@

from

P

V

(

i

)

=

n

(

i

)

R

T

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGqbGaam

OvamaaCaaaleqabaWaaeWaaeaacaWGPbaacaGLOaGaayzkaaaaaOGa

eyypa0JaamOBamaaCaaaleqabaWaaeWaaeaacaWGPbaacaGLOaGaay

zkaaaaaOGaamOuaiaadsfaaaa@4114@

and

P

V

=

[

∑

i

n

(

i

)

]

R

T

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGqbGaam

Ovaiabg2da9maadmaabaWaaabuaeaacaWGUbWaaWbaaSqabeaadaqa

daqaaiaadMgaaiaawIcacaGLPaaaaaaabaGaamyAaaqab0GaeyyeIu

oaaOGaay5waiaaw2faaiaadkfacaWGubaaaa@435E@

.

Then,

(14)

m

˙

o

u

t

(

i

)

=

n

(

i

)

∑

i

n

(

i

)

m

˙

o

u

t

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGTbGbai

aadaWgaaWcbaGaam4BaiaadwhacaWG0baabeaakmaaCaaaleqabaWa

aeWaaeaacaWGPbaacaGLOaGaayzkaaaaaOGaeyypa0ZaaSaaaeaaca

WGUbWaaWbaaSqabeaadaqadaqaaiaadMgaaiaawIcacaGLPaaaaaaa

keaadaaeqbqaaiaad6gadaahaaWcbeqaamaabmaabaGaamyAaaGaay

jkaiaawMcaaaaaaeaacaWGPbaabeqdcqGHris5aaaakiqad2gagaGa

amaaBaaaleaacaWGVbGaamyDaiaadshaaeqaaaaa@4C91@

Porosity

The isenthalpic model is also used for porosity. In this case, you can define the

surface for outgoing flow:

(15)

A

e f f

=

C

p s

⋅ A r e

a

p s

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaadwgacaWGMbGaamOzaaqabaGccqGH9aqpcaWGdbWaaSba

aSqaaiaadchacaWGZbaabeaakiabgwSixlaadgeacaWGYbGaamyzai

aadggadaWgaaWcbaGaamiCaiaadohaaeqaaaaa@45FC@

or,

(16)

A

e f f

=

C

p s

( t ) ⋅

Area

p s

( P −

P

e x t

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaadwgacaWGMbGaamOzaaqabaGccqGH9aqpciGGdbWaaSba

aSqaaiaadchacaWGZbaabeaakiaacIcacaWG0bGaaiykaiabgwSixl

GacgeacaGGYbGaaiyzaiaacggadaWgaaWcbaGaamiCaiaadohaaeqa

aOGaaiikaiaadcfacqGHsislcaWGqbWaaSbaaSqaaiaadwgacaWG4b

GaamiDaaqabaGccaGGPaaaaa@4F5D@

Where,

C

p s

( t )

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaciGGdbWaaS

baaSqaaiaadchacaWGZbaabeaakiaacIcacaWG0bGaaiykaaaa@3B9D@

Function of

fct_ID cps

Area

p s

( P −

P

e x t

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaciGGbbGaai

OCaiaacwgacaGGHbWaaSbaaSqaaiaadchacaWGZbaabeaakiaacIca

caWGqbGaeyOeI0IaamiuamaaBaaaleaacaWGLbGaamiEaiaadshaae

qaaOGaaiykaaaa@4313@

Function of

fct_ID aps

It is also possible to define closure of the porous surface when contacts occurs by

defining the interface option I bag 1 .