Stress Life Method (Non-Welded)

Uniaxial Fatigue Analysis, using S-N (stress-life) approach for predicting the life (number of loading cycles) of a structure under cyclical loading may be performed by using HyperLife.

The stress-life method works well in predicting fatigue life when the stress level in the structure falls mostly in the elastic range. Under such cyclical loading conditions, the structure typically can withstand a large number of loading cycles; this is known as high-cycle fatigue. When the cyclical strains extend into plastic strain range, the fatigue endurance of the structure typically decreases significantly; this is characterized as low-cycle fatigue. The generally accepted transition point between high-cycle and low-cycle fatigue is around 10,000 loading cycles.

Read more about Uniaxial Fatigue Analysis, using S-N (stress-life) approach for predicting the life here Uniaxial Fatigue Analysis.

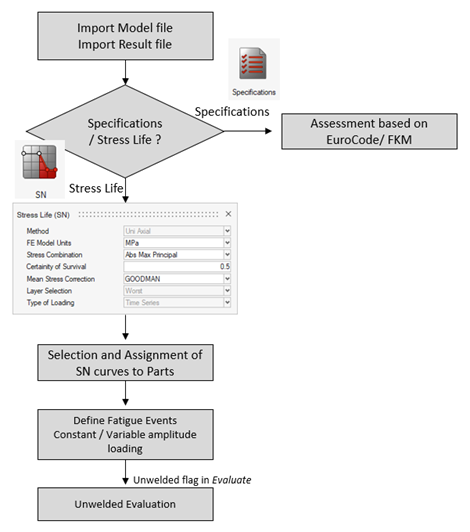

The workflow using Stress Life approach for base metal evaluation in HyperLife Weld Certification is highlighted in Figure 1.

Refer to Materials and its assignment here: Materials.

| Parameter | Description |

|---|---|

| Material |

Material assigned to the Part. Material list for selection is created by adding Materials to Assign Material list from Material Db, My Material, or HM Material tabs. |

| Material Units | Unit of the assigned material. |

| Plot | Stress Life plot of the assigned material. |

| FL | Fatigue Limit of the assigned material. |

| SE |

Standard Error of Log(N) of the assigned material. Default = 0.0 (Real ≥ 0.0) |

| FKMMSS |

Mean Stress Sensitivity parameters for mean stress correction based on FKM Guidelines. Default: MSS1 = 0.0 MSS2 = 0.15 MSS3 = 0.0 MSS4 = 0.0 |

| Scale | Scale is used to modify the calculated stress during the stress history generation. |

| Offset | Offset is used to modify the calculated stress during the stress history generation. |

| Finish | Material Surface Finish, a result of manufacturing process. NONE (Default) POLISH GROUND MACHINE HOTROLL FORGE Or USER (any float value between 0.0 and 1.0.) When it is a float value, it will be used to modify the fatigue limit by being multiplied with the original fatigue limit. Read more: Other Factors Affecting Fatigue. |

| Surft Treatment |

Material Surface Treatment for Material S-N Curve, a process used to enhance the fatigue life. NONE (Default) NITRIDED SHOTPEEN COLDROLL Or USER any float value greater than 0.0. When it is a float value, it will be used to modify the fatigue limit by multiplied with the original fatigue limit. Read more: Other Factors Affecting Fatigue. |

| Temperature factor |

Temperature influence can be accounted by applying the temperature factor to modify the fatigue endurance limit FL. Read more: Other Factors Affecting Fatigue. |

| Kf |

Fatigue strength reduction factor. Default = 1.0 (Real ≥ 1.0) Read more: Other Factors Affecting Fatigue. |

Stress life for Evaluation Domain: Unwelded is supported for shell elements via elemental or corner data stresses and solid elements via corner data stresses only.

SN evaluation in HyperLife Weld Certification supports Time Series loading and allows creation of Superposition or Sequential fatigue events. Refer: Create Events.

Utilization Based on Target Life

In addition to damage and safety factor assessment, Stress Life workflow supports Utilization output.

The flag to activate Utilization is available in Evaluate Context as Endurance limit, activating Safety factor calculation and its criteria.

Utilization Factor Calculation

Utilization Factor is calculated by .

Safety factor is calculated as highlighted in Safety Factor.