ACU-T: 6501 Flow Through Porous Medium with Physical Velocity

Tutorial Level: Intermediate

Prerequisites

This tutorial provides the instructions for setting up, solving, and viewing results for a simulation of a flow through porous medium that is specified using the physical velocity input method. Prior to starting this tutorial, you should have already run through the introductory tutorial, ACU-T: 1000 Basic Flow Set Up, and have a basic understanding of HyperMesh CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperMesh CFD and AcuSolve.

Problem Description

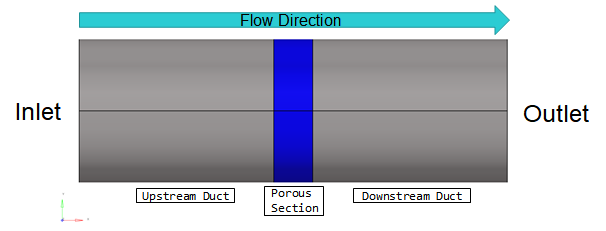

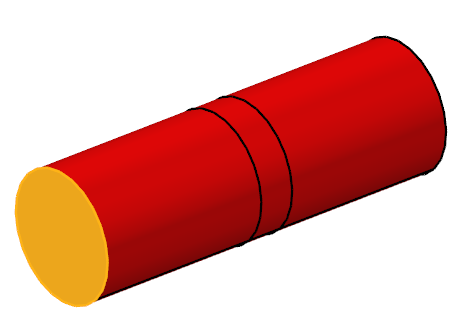

The problem to be addressed in this tutorial is shown schematically in the figure below. It consists of a cylindrical channel with a porous medium in the flow section. As the flow passes through this section, a pressure drop is observed. In this simulation, an inlet velocity will be assigned to the flow and pressure drop across the porous medium will be calculated. The length of the porous section is 0.06 m and the fluid is defined as air fluid with a density of 1.225 kg/m3 and a molecular viscosity of 1.781e-5 kg/m-s. The inlet velocity of the flow is 0.2 m/s.

The porosity is defined as the ratio of the volume of fluid to the total volume. With the superficial velocity approach, the porosity is set to 1 and the flow velocity is calculated as if there is no obstruction to the flow. When using the porous medium with physical velocity, the porosity of the volume is considered when calculating the flow velocity. This allows for a more physical representation of the flow within these components. In this tutorial, you will use a porosity value of 0.5.

Start HyperMesh CFD and Open the HyperMesh Database

- Start HyperMesh CFD from the Windows Start menu by clicking .

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 2.

The Open File dialog opens. - Browse to the directory where you saved the model file. Select the HyperMesh file ACU-T6501_PorousMediaPhysicalVelocity.hm and click Open.

- Click .

-

Create a new directory named PorousMediaPhysical and navigate into this directory.

This will be the working directory and all the files related to the simulation will be stored in this location.

- Enter PorousMediaPhysical as the file name for the database, or choose any name of your preference.

- Click Save to create the database.

Validate the Geometry

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Set Up Flow

Set Up the Simulation Parameters and Solver Settings

-

From the Flow ribbon, click the Physics tool.

Figure 4.

The Setup dialog opens. -

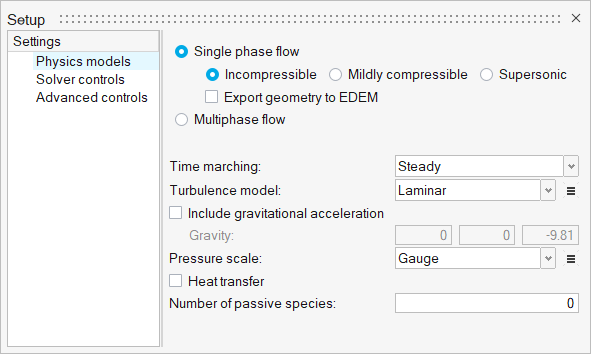

Under the Physics models setting:

- Set Time marching to Steady.

- Select Laminar as the Turbulence model.

Figure 5.

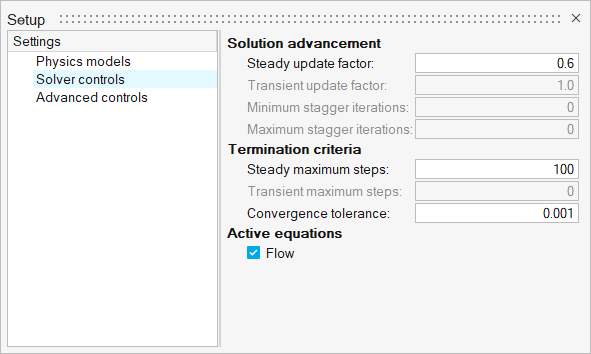

- Click the Solver controls setting.

-

Confirm that the Steady update factor and the Steady maximum steps are set to

0.6 and 100,

respectively.

Figure 6.

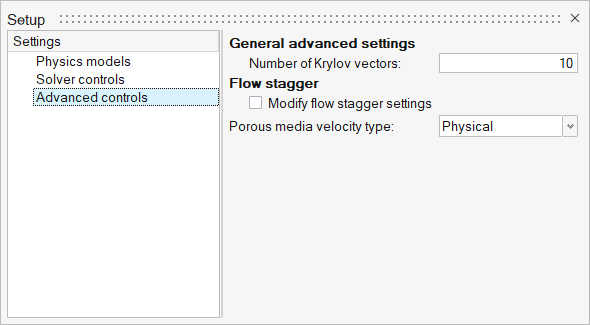

- Click the Advanced controls setting.

-

Confirm that the Porous media velocity type is set to

Physical.

Figure 7.

Assign Material Properties

-

From the Flow ribbon, click the Material tool.

Figure 8.

-

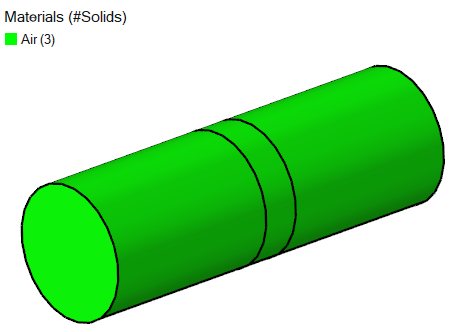

Verify that the material Air is assigned to the model's three solids.

Figure 9.

Define the Porous Medium

-

From the Flow ribbon, Porous

tool group, click the Cartesian Porous Media tool.

Figure 10.

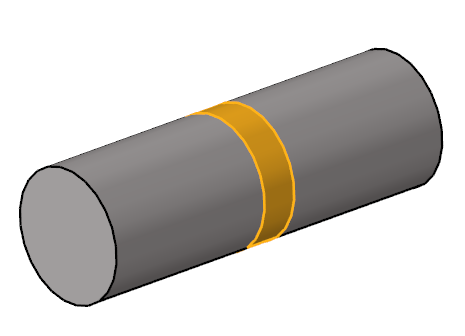

-

Select the middle solid on the model.

Figure 11.

- On the guide bar, click Orientation.

- Left-click to place a point anywhere on the selected solid.

-

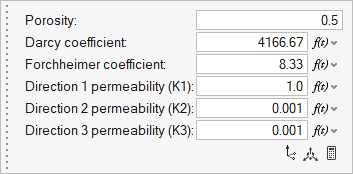

In the microdialog, enter the following values for the

coefficients.

Figure 12.

-

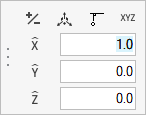

In the microdialog, click

to open the Orient tool then verify that the direction is aligned to the

global x-axis.

to open the Orient tool then verify that the direction is aligned to the

global x-axis.

Figure 13.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

Assign the Flow Boundary Conditions

-

From the Flow ribbon, Profiled

tool group, click the Profiled Inlet tool.

Figure 14.

-

Select the inlet face.

Figure 15.

-

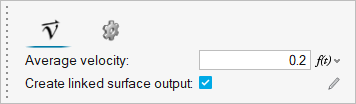

In the microdialog, set the average velocity to

0.2.

Figure 16.

-

On the guide bar, click

to execute

the command and exit the tool.

to execute

the command and exit the tool.

-

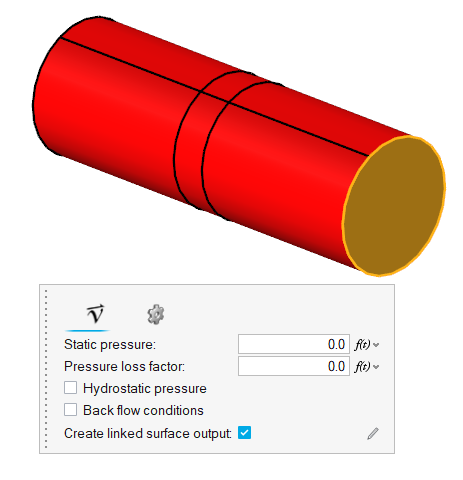

Click the Outlet tool.

Figure 17.

-

Select the outlet face.

Figure 18.

-

Accept the default parameters and then click

on the

guide bar.

on the

guide bar.

Generate the Mesh

-

From the Mesh ribbon, click the

Volume tool.

Figure 19.

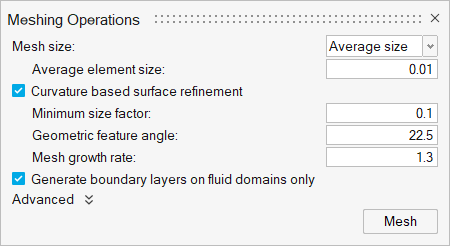

The Meshing Operations dialog opens.Note: If the model has not been validated, you are prompted to create the simulation model before running the batch mesh. - Check that the Average element size is 0.01.

-

Accept all other default parameters.

Figure 20.

-

Click Mesh.

The Run Status dialog opens. Once the run is complete, the status is updated and you can close the dialog.Tip: Right-click the mesh job and select View log file to view a summary of the meshing process.

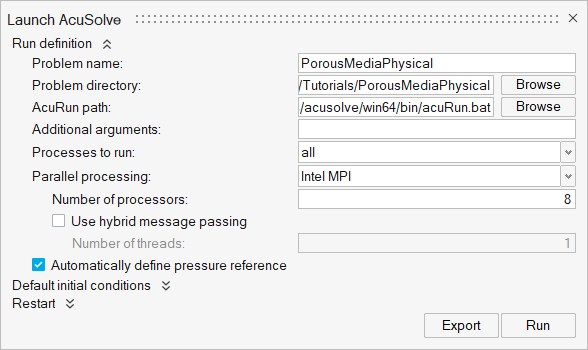

Run AcuSolve

-

From the Solution ribbon, click the Run tool.

Figure 21.

- Set the Parallel processing option to Intel MPI.

- Optional: Set the number of processors to 4 or 8 based on availability.

-

Leave the remaining options as default and click

Run to launch AcuSolve.

Figure 22.

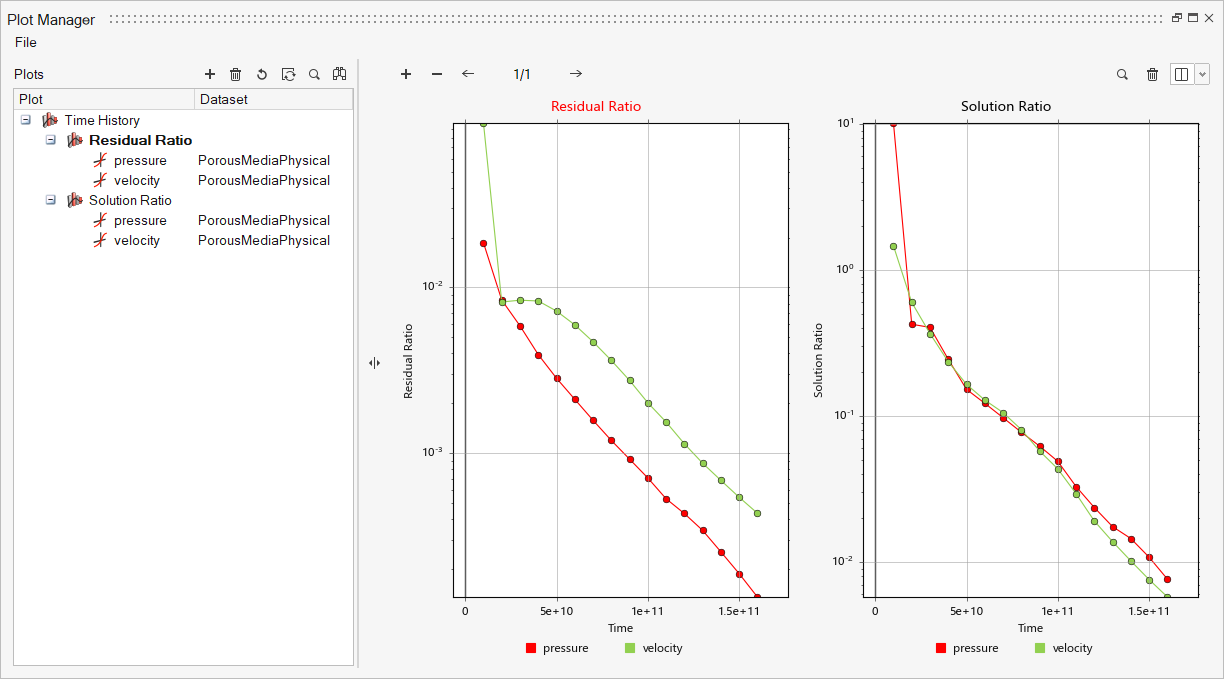

Post-Process the Results

-

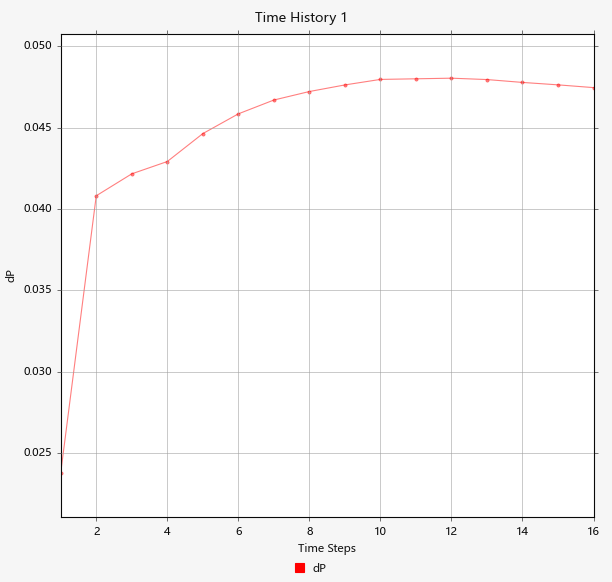

In the Run Status dialog, right-click AcuSolve run and select Plot time

history to launch the Plot Manager.

Figure 23.

-

Click

to create a new plot.

to create a new plot.

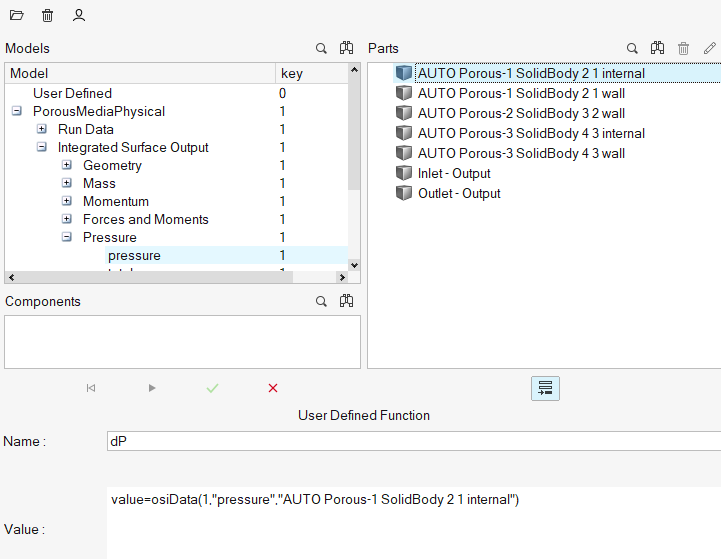

- Right-click User Defined under the Model panel to create a user-defined function.

- In the Data Tree, expand and then select pressure.

- In the Name field, enter dP.

- In the Value field, type value=.

-

Under Parts, choose AUTO Porous-1 SolidBody_2_1 internal

and then click

to insert the field as part of the value, as shown

below.

to insert the field as part of the value, as shown

below.

Figure 24.

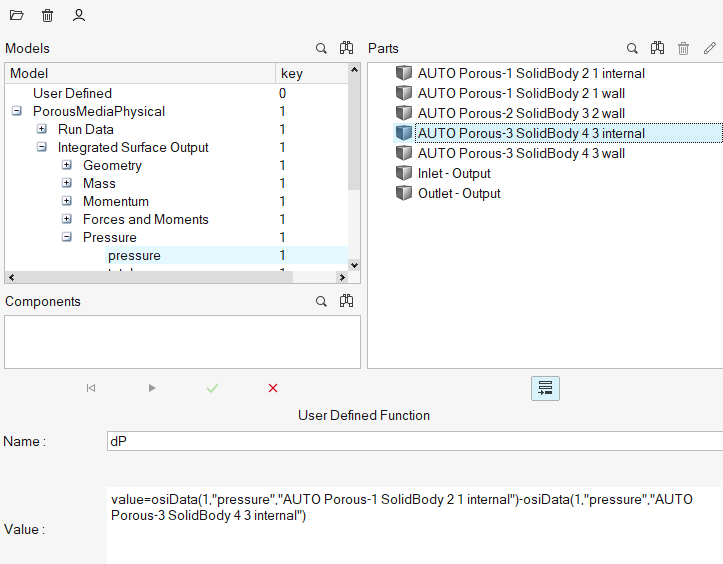

- Type - at the end of the user-defined function value.

-

Under Parts, choose AUTO Porous-3 SolidBody_4_3 internal

and then click

to insert the field as part of the value.

to insert the field as part of the value.

-

Click

to add the user-defined function.

to add the user-defined function.

Figure 25.

-

Click the x axis to switch to Time Steps.

Figure 26.

The pressure drop across the porous inlet (AUTO Porous-1 SolidBody_2_1 internal) and porous outlet (AUTO Porous-3 SolidBody_4_3 internal) surfaces is 0.047 Pa.

Summary

In this tutorial, you learned how to set up and solve a flow simulation with porous medium using the physical velocity formulation. This implementation allows you to specify values of porosity in the fluid to emulate the fluid packing within a porous media. You started by importing the HyperMesh CFD input database and then you defined the porous medium. Next, you assigned the flow boundary conditions and generated the mesh. Once the solution was computed, you created a plot of the pressure drop across the porous section using HyperMesh CFD.