ANSYS

ANSYS-specific checks used to calculate element quality for 2D and 3D elements.

2D and 3D Element Checks

These checks apply to both types of elements, but when applied to 3D elements they are generally applied to each face of the element. The value of the worst face is reported as the 3D element’s overall quality value.

Additional element checks not listed here are not part of the solver’s normal set of

checks, and therefore use HyperMesh check methods.

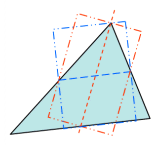

- Aspect Ratio (tria)

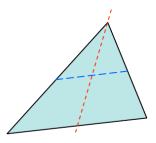

- For tria elements, a line is drawn from one node to the midpoint of the

opposite edge. Next, another line is drawn between the midpoints of the

remaining two sides. These lines are typically not perpendicular to each

other or to any of the element edges, but provide four points (three

midpoints plus the vertex).

Figure 1.

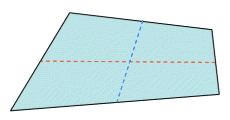

- Aspect Ratio (quad)

- If the element is not flat, it’s projected to a plane which is based on the average of the element’s corner normals. All subsequent calculations are based on this projected element rather than the original (curved) element.

- Interior Angles

- Maximum and minimum values are evaluated independently for triangles and quadrilaterals.

- Jacobian

- Deviation of an element from its ideal or "perfect" shape, such as a triangle’s deviation from equilateral. The Jacobian value ranges from 0.0 to 1.0, where 1.0 represents a perfectly shaped element. The determinant of the Jacobian relates the local stretching of the parametric space which is required to fit it onto the global coordinate space.

- Length (min)

- Minimum element lengths are calculated using one of two methods:

- The shortest edge of the element. This method is used for non-tetrahedral 3D elements.

- The shortest distance from a corner node to its opposing edge (or face, in the case of tetra elements); referred to as "minimal normalized height".

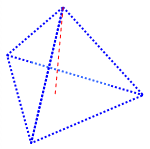

Figure 5.

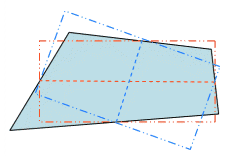

- Angle Deviation (Skew)

- Only applicable to quadrilateral elements, and relies upon the angles between adjacent legs at each corner node (that is, the interior angles at each corner). Each angle is compared to a base of 90 degrees, and the one with the largest deviation from 90 is reported as the angle deviation. Triangular elements are given a value of zero.

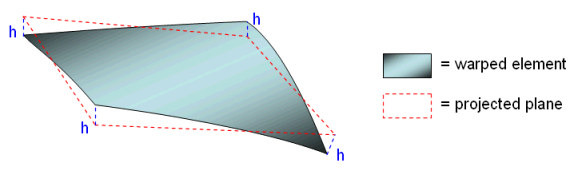

- Warping Factor

- Only applicable to quadrilateral elements as well as the quadrilateral faces of 3D bricks, wedges, and pyramids.

3D Element Only Checks

ANSYS does not use any exclusively 3D checks within HyperMesh CFD, but HyperMesh CFD does use its own when ANSYS is set as the solver. For details on 3D checks, refer to HyperMesh.