Turbulent Flow Over an Oscillating Rigid Body Assembly

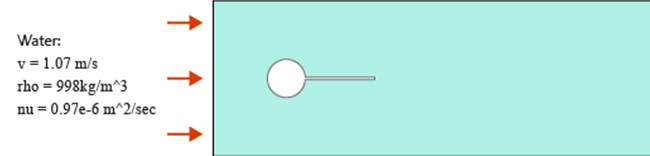

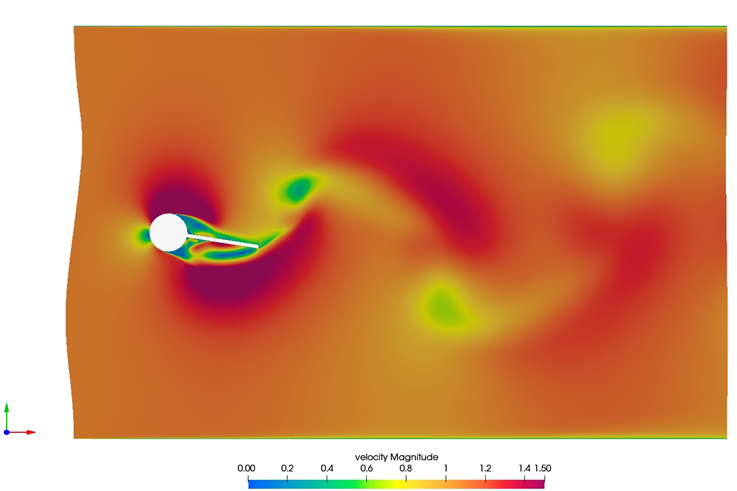

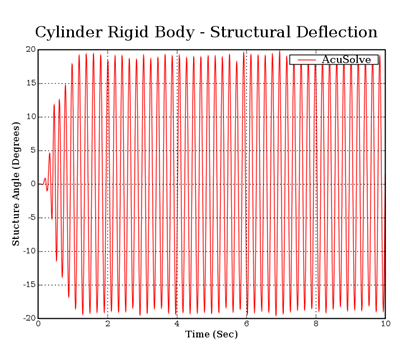

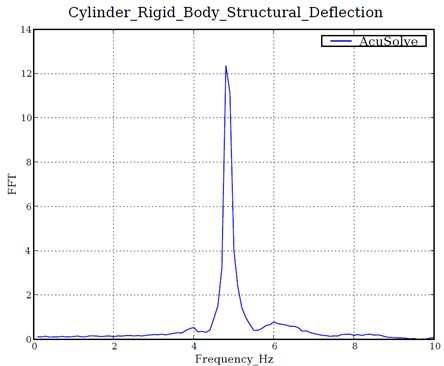

In this application, AcuSolve is used to simulate the fluid-structure interaction of a fluid moving over a cylinder/plate assembly. AcuSolve results are compared with experimental results as described in Gomes and Lienhart (2009). The close agreement of AcuSolve results with the experimental results validates the ability of AcuSolve to model cases in which the fluid forces lead to structural motions.

Problem Description

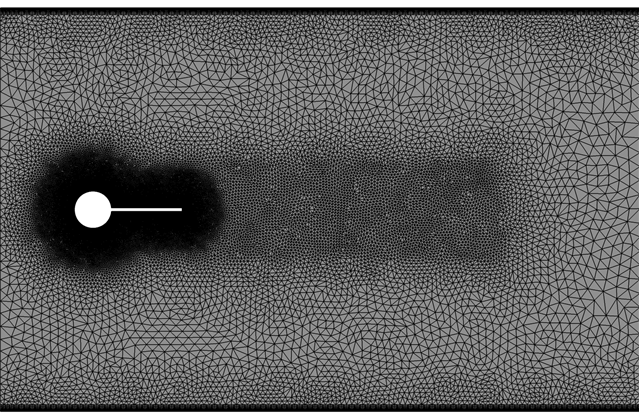

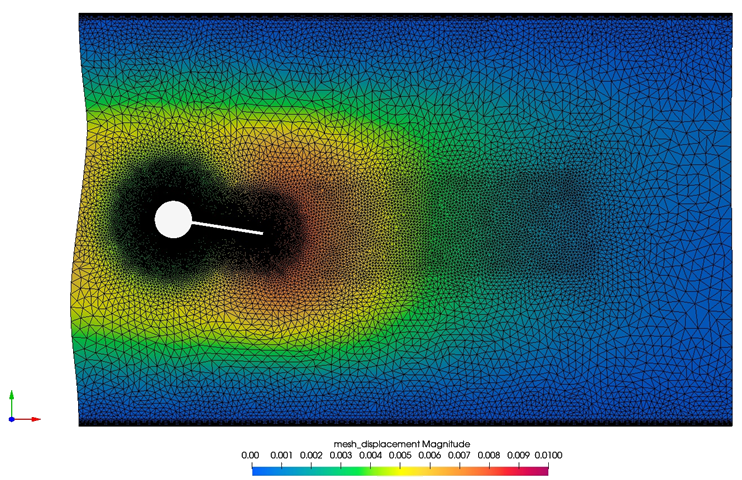

The simulation was performed as a two dimensional problem by constructing a volume mesh that contains a single layer of elements extruded in the cross stream direction, normal to the flow plane and by imposing symmetry boundary conditions on the extruded planes. The upper and lower walls are specified as no-slip and the inlet velocity is specified to match the conditions of the experiment (Gomes and Lienhart 2009).

AcuSolve Results

Summary

The AcuSolve solution compares well with experimental data for flow past an oscillating cylinder/plate assembly. In this application, water moves over the cylinder/plate assembly, giving rise to unsteady loading that causes the body to rotate as a rigid body. The good agreement with the natural frequency of oscillation compared to the experimental data demonstrates that AcuSolve is capable of predicting fluid forced motion with an internal rigid body dynamic solver.

Simulation Settings for Turbulent Flow Over an Oscillating Rigid Body Assembly

SimLab database file: <your working directory>\cylinder_rigidbody_turbulent\cylinder_rigidbody_turbulent.slb

Global

- Problem Description

- Flow - Transient

- Turbulence equation - SST

- Moving Mesh - Computed

- Auto Solution Strategy

- Final Time - 10.0

- Initial Time Increment- 0.005

- Convergence tolerance- 0.001

- Max stagger iterations- 3

- Material Model

- Water

- Type- Constant

- Density- 998.0 kg/m3

- Viscosity- 0.00096806 kg/m*sec

- Water

- Mesh Motion

- RigidBody

- Type- Rigid Body Dynamic

- Z rotation- Active

- Mass- 0.2089 kg

- Dyadic

- X-X - 3.7 e-5 kg-m2

- Y-Y- 3.7 e-5 kg-m2

- Z-Z - 3.7 e-5 kg-m2

- Type- Rigid Body Dynamic

Model

- RigidBody

- Volumes

- Volume

- Element Set

- Material model- Water

- Element Set

- Volume

- Surfaces

- Body

- Simple Boundary Condition

- Type- Wall

- Mesh displacement BC type- Fixed

- Mesh motion- RigidBody

- Interpolated Motion Surface

- Simple Boundary Condition

- Bottom

- Simple Boundary Condition

- Type- Wall

- Mesh displacement BC type- Fixed

- Interpolated Motion Surface

- Simple Boundary Condition

- Inflow

- Simple Boundary Condition

- Type- Inflow

- Inflow type- Velocity

- X Velocity- 1.07 m/sec

- Turbulence input type- Auto

- Turbulence intensity type- High

- Advanced Options

- Nodal Boundary Conditions

- X-velocity

- Type- Linear

- Precedence- 2

- Curve fit variable- Y coordinate

- Curve fit values- Provided

- Y-velocity

- Type- Zero

- Z-velocity

- Type- Zero

- Simple Boundary Condition

- Bottom

- Simple Boundary Condition

- Type- Wall

- Mesh displacement BC type- Fixed

- Mesh motion- RigidBody

- Simple Boundary Condition

- Outflow

- Simple Boundary Condition

- Type- Outflow

- Simple Boundary Condition

- Top

- Simple Boundary Condition

- Type- Wall

- Mesh displacement BC type- Fixed

- Simple Boundary Condition

- maxZ

- Simple Boundary Condition

- Type- Slip

- Simple Boundary Condition

- minZ

- Simple Boundary Condition

- Type- Slip

- Simple Boundary Condition

- Body

References

Gomes, J. P. and Lienhart, H. (2009) Experimental Benchmark: Self-excited Fluid-structure Interaction Test Cases, in Fluid-Structure Interaction II: Modeling, Simulation, Optimization, Bungartz, H. J., Mehl, M., Schafer, M. (eds.), 383-412, Springer-Verlag.Ryhming.