Tutorial: Adding a Core Component

See the difference in porosity of a solid model and the same model with a core.

In this exercise, you will learn how to analyze the effect a sand core has on casting.

Model file is available in the tutorial_models folder in the installation directory in Program Files\Altair\2024\InspireCast2024\tutorial_models\core.x_b.

Import Geometry

- Launch Inspire Cast.

-

Click Open Model on the Files icon and browse to the

tutorial model file in the installation directory, or drag-and-drop the file

into the modeling window.

Designate a Casting Part

Select casting geometries with the Cast Part tool.

Important: A cast part must be defined before performing any other

operation.

-

On the Cast Part icon, click Designate

Casting Part.

-

Left-click to select which candidate is a cast part.

Parts are automatically detected and highlighted based on your cursor position.The selected part is highlighted red.

-

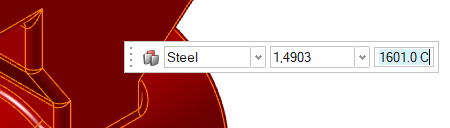

In the microdialog, select Steel

as the material and select 1,4903 as the alloy for the

part.

- Right-click and mouse through the check mark to exit, or double-right-click.

Set Gravity Direction

-

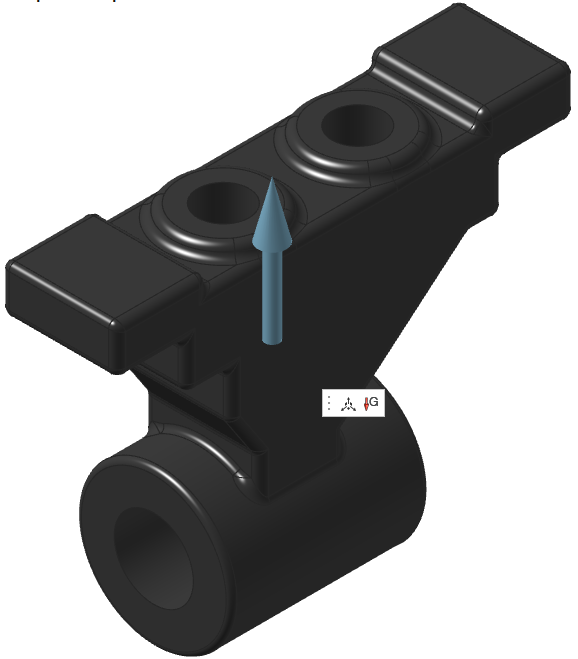

On the Cast Part tool, click Set Gravity

Direction.

-

Click the Gravity icon in the microdialog to align gravity to the normal of a selected

surface.

-

Click one of the bottom surfaces of the part.

Gravity will automatically be realigned perpendicular to the selected surface.

Gravity will automatically be realigned perpendicular to the selected surface.

- Right-click and mouse through the check mark to exit, or double-right-click.

Add a Gate

-

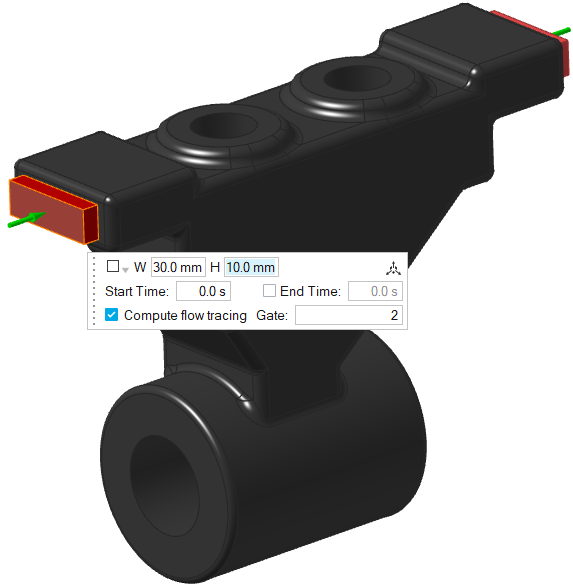

On the Gate icon, click Add/Edit

Gate.

-

Create two gates: select a surface of the model to place a gate there, and

enter the dimensions in the microdialog as shown below.

Add a Core

-

Click the Components tool.

Click the Core tool in the secondary tool group.

-

Cavities that can become cores are shown in gray. Click to select which

candidate is a core and automatically create the core volume.

The selected part is highlighted red.

-

In the microdialog, select

Silica-Sand as the material.

- Right-click and mouse through the check mark to exit, or double-right-click.

Run Analysis

-

On the Analysis icon, click Run

Analysis.

-

In the Run Analysis dialog, select the

Stages tab and enter the Element

size manually or define the Average

Thickness. You can also select number of cycles in the process

by selecting Use cycling.

-

Select the Advanced tab to manually select mesh factors

for components like gate, mold, runner, riser, etc.

-

Select the Stages tab and click

Run.

Note: The mold will automatically generate when you click Run.Note: Once the simulation calculation is finished, a green flag will appear on the analyze icon.

Analyze Results

-

Click the green flag on the Analyze

tool.

You can also select the run and click View Now in the Run Status window.

tool.

You can also select the run and click View Now in the Run Status window.

-

Click Solid Fraction under Result

Types.

-

Set the Solid Fraction percentage to

0.70.

Note: The solid fraction value is set to 0.7 by default. In most cases, this corresponds to the value at which the liquid stops flowing. -

Click Play

to start the animation.

In the animation, solidified material (above 0.7) is transparent, while liquid material (below 0.7) is shown colored. Shrinkage porosity is more likely to occur in isolated areas.

-

Click Demolding under Stage and

click Porosity under Result

Types.

-

Set the percentage to 100%.

There are no regions of 100% porosity in the finished part.