Define Hot Runner

Identify existing geometry as hot runners and define the hot runner system.

Create a runner system geometry before defining it as a hot runner system.

-

Click the Select Hot Runner icon, then select parts in

the model geometry to designate them as part of the hot runner system.

-

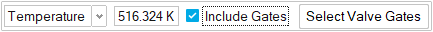

Use the guidebar to select between an insulated or heated runner, set a heated

runner's temperature, and if desired, enable valve gates.

-

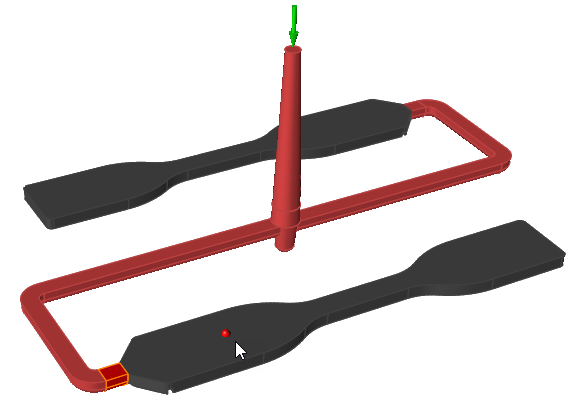

Optional: Click Select Valve Gates to designate one or

more valve gates.

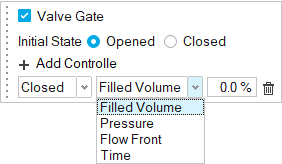

- Select a gate. Enable the Valve Gate option in the microdialog.

- Set the gate's initial state to opened or closed, and add controllers to change the gate's state as needed.

Note:- Two or more gates are required for this option.

- At least one gate must start in the opened state.

- Each valve gate must be designated individually.

- You may add more than one control to a single gate.

- You can set a gate's state to change based on filled volume, pressure at a selected point in the cavity, flow front position, or elapsed time.

Control Option Description Note Filled Volume Defines the control as a percentage of the total material volume. Enter the percentage. Pressure Defines the control as the pressure at a specified point on the model. - Enter the pressure.

- Click the point icon

, then click a point on

the model where you want the specified pressure to

control the valve gate.

, then click a point on

the model where you want the specified pressure to

control the valve gate.

Flow Front Defines the control as the material flow at a specified point on the model. Click the point icon  , then click a point on the

model where you want the flow front to control the valve

gate.

, then click a point on the

model where you want the flow front to control the valve

gate.Time Defines the control as a duration of time. Enter the time in seconds.