Motor Factory

Generic functions

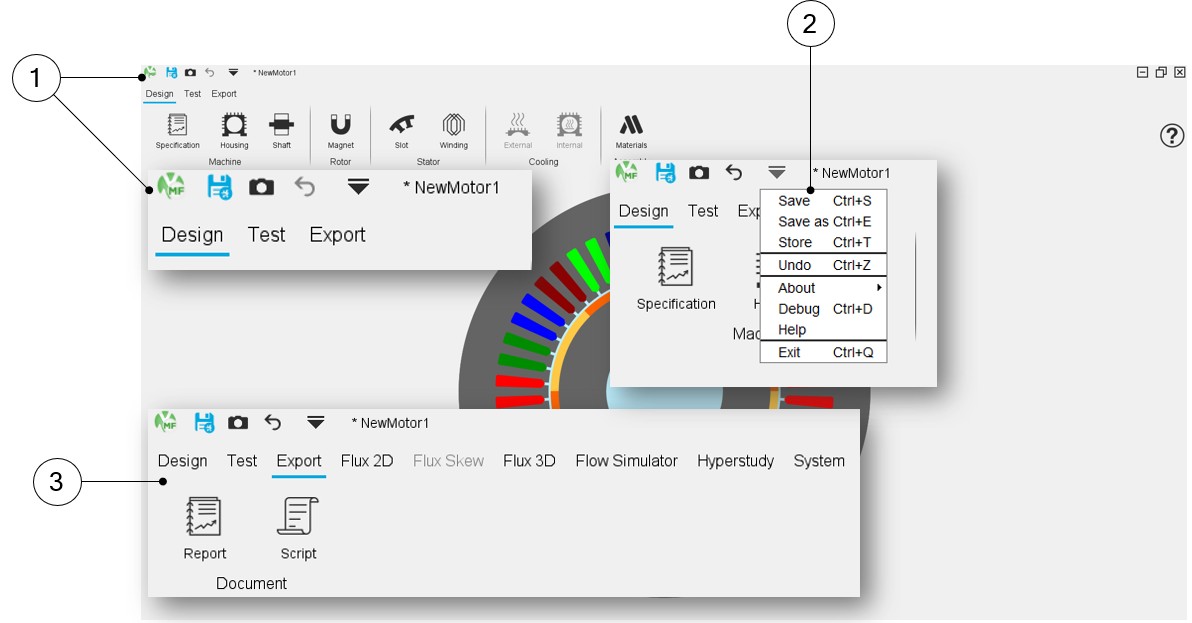

Save, Store, Undo are also available in the top left-hand corner of the screen next to the drop-down menu in which generic functions such as Save, Save as, Store, Undo, About, Debug, Help and Exit can be selected as well.

|

|

| FluxMotor – Motor Factory – GUI and workflows - Generic functions | |

| 1 | Access to the generic functions such as Save, Save as, Store, Undo, About, Debug, Help and Exit |

| 2 | Drop-down menu in which generic functions can be reached |

| 3 | Clicking on Export displays the list of applications to which exports are possible. |

Design area

Interface graphics have been lightened. The number of grayscales has been reduced, and separator bars have been removed.

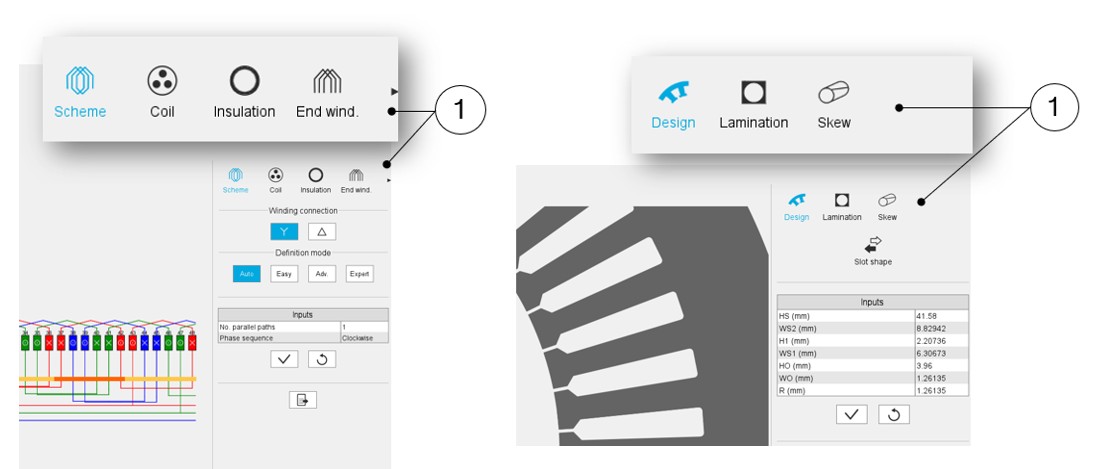

Selection scrollbars have been deployed and homogenized in all design environments (Machine, Rotor, Stator, Cooling and Assembly).

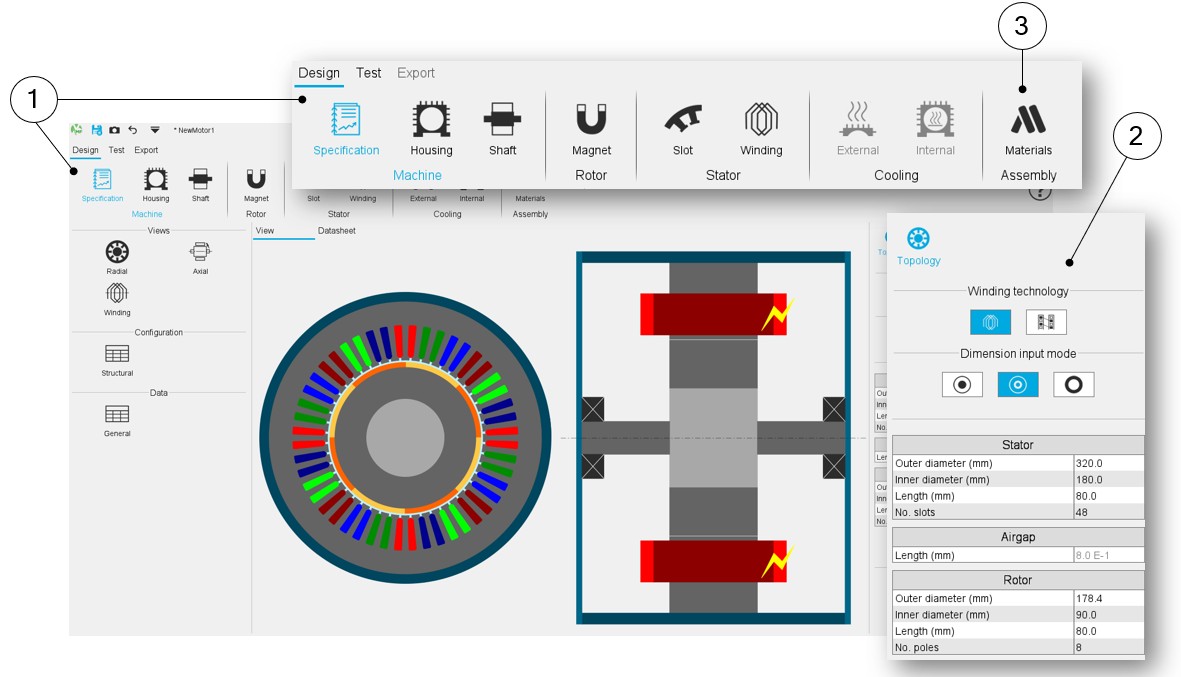

A new environment has been created: Specification, in which we find the definition of what was previously called Topology, which enables us to define the machine's structural data.

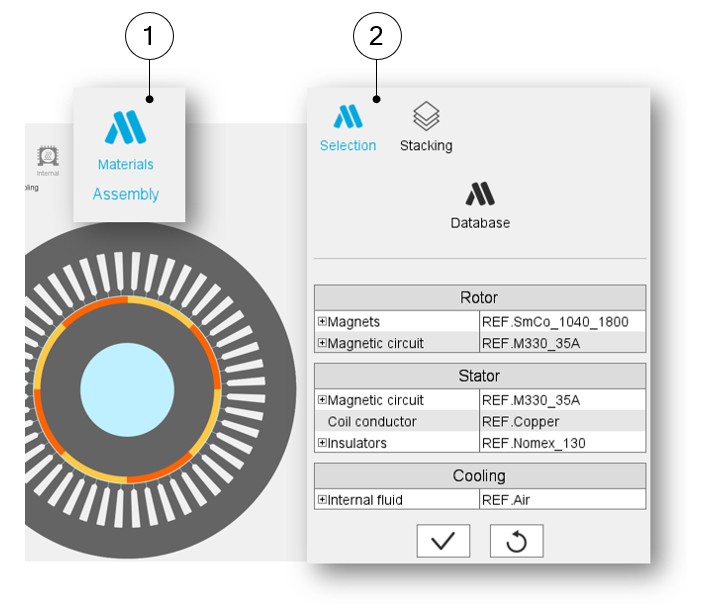

Another environment has been added: Assembly, in which one can select the materials needed to build the machine, as well as define the stacking factor to be considered for the stator and the rotor.

|

|

| FluxMotor – Motor Factory – GUI and workflows – Design – Selection scrollbars | |

| 1 | Selection scrollbars have been deployed and homogenized in all design environments (examples for winding and slot). |

|

|

| FluxMotor – Motor Factory – GUI and workflows – Design | |

| 1 | Specification is a new area in which we find the definition of what was previously called Topology, which enables us to define the machine's structural data. |

| 2 | Topology enables the user to define the machine's structural data. |

| 3 | Assembly, is a new area to select the materials needed to build the machine, as well as define the stacking factor to be considered for the stator and the rotor |

|

|

| FluxMotor – Motor Factory – GUI and workflows – Design - Assembly | |

| 1-2 | Assembly, is a new area to select the materials needed to build the machine, as well as define the stacking factor to be considered for the stator and the rotor. |

Test Area

As for the Design environment, interface graphics have been lightened.

However, the most significant change in the test space is that now, the selection of tests to run is done from the top bar.

For each test family, clicking on a package of tests deploys the list of available tests. Then, clicking on a test opens the dedicated environment where all the elements necessary for its execution (settings and input parameters) are available below.

|

|

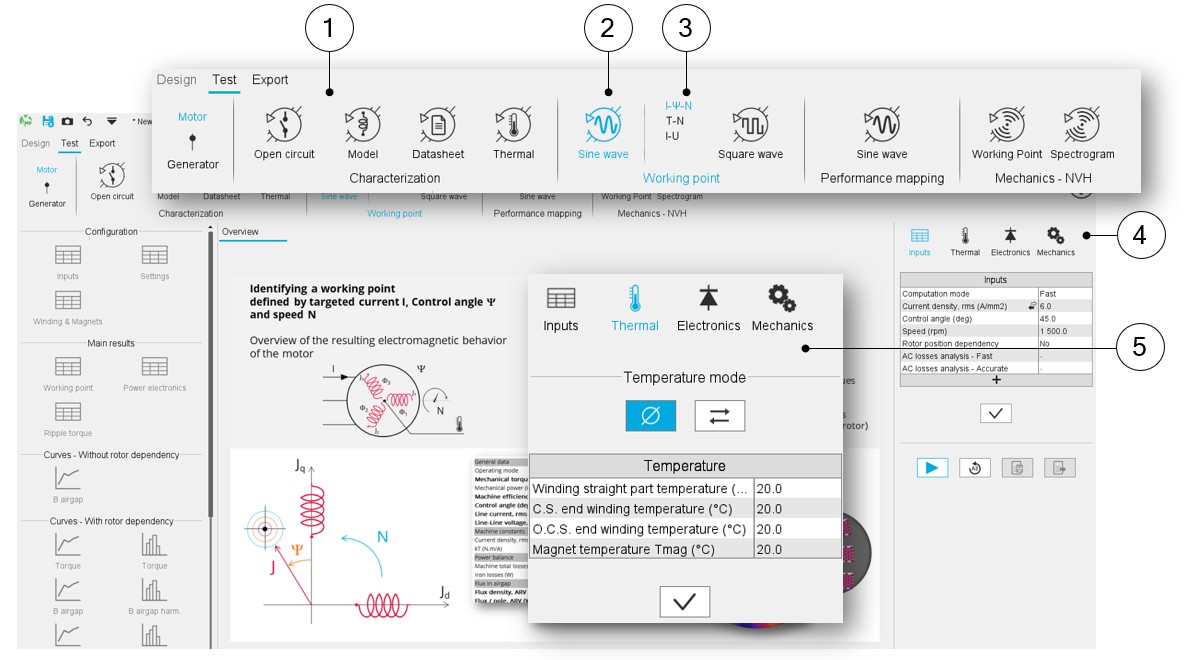

| FluxMotor – Motor Factory – GUI and workflows – Test area - Selection of tests to run | |

| 1 | The selection of tests to run is done from the top bar. |

| 2-3 | Clicking on a package of tests deploys the list of available tests. |

| 4 | The settings are now accessible via a Selection scrolling bar, similar to what's found in the Design environment. |

| 5 | When one clicks on a setting section, the associated user inputs are directly available below. |

On the other hand, to simplify the presentation of user inputs, the selection of the operating mode and/or associated convention of the machine has been moved to the top left of the screen.

A button allows the user to switch from Motor mode to Generator mode.

|

|

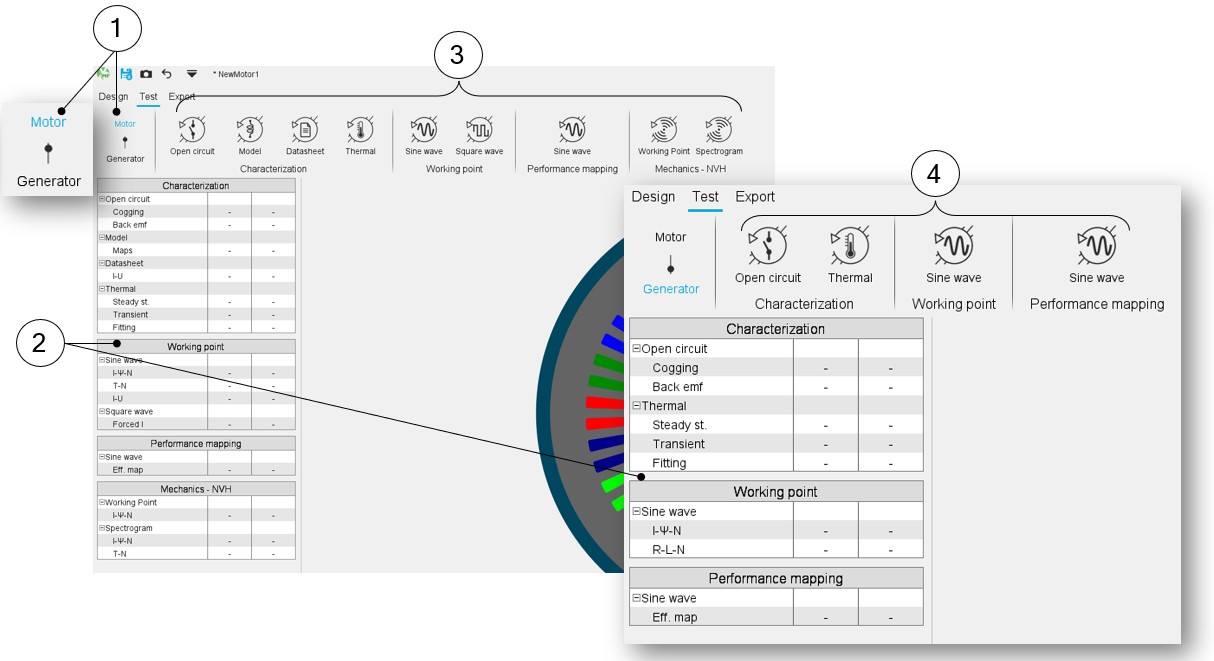

| FluxMotor – Motor Factory – GUI and workflows - Test area – Motor/Generator mode | |

| 1 | Selection of the operating mode and/or associated convention of the machine. |

| 2 | The available tests are filtered according to the selection of the operating mode, Motor or Generator. |

|

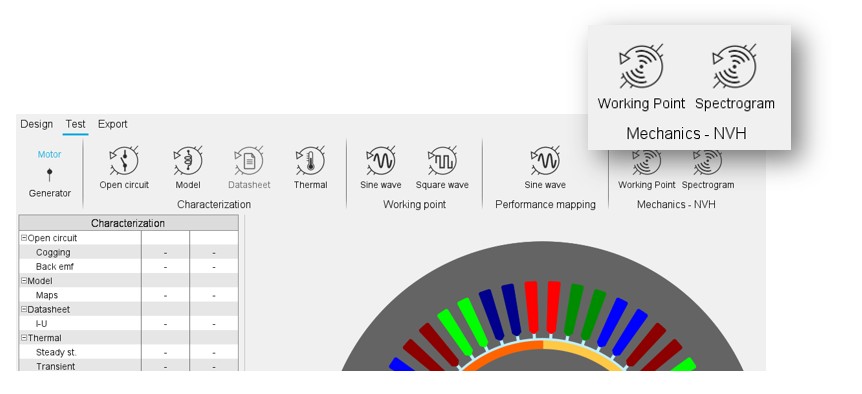

| FluxMotor – Motor Factory – Test area - Mechanics – NVH |

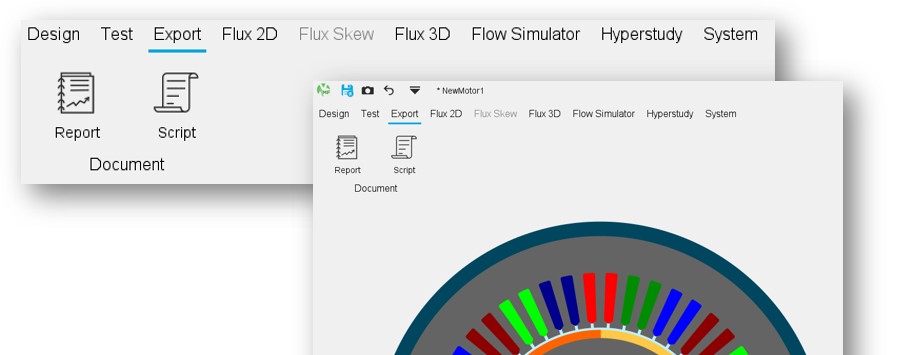

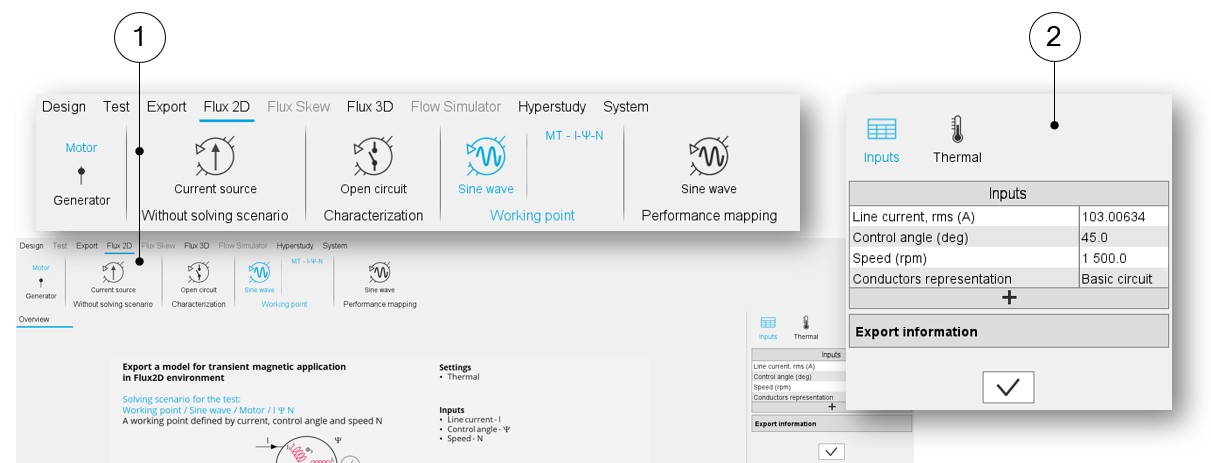

Export Area

The Export environment was built according to the same principles as those adopted for the other areas (Design and Test). The objective is to standardize Motor Factory environments in order to simplify user workflows regardless of where you are located in Motor Factory (Design, Tests and Export).

When one clicks on Export, the list of applications to which exports are possible, is displayed next to the label “Export” (such as Flux 2D, Flux Skew, Flux 3D, Flow Simulator, HyperStudy, System (for PSIM and Twin Activate).

|

| FluxMotor – Motor Factory – GUI and workflows - Export area – Report and Script |

Then, the procedure is identical to that proposed in the Test environment.

When selecting an application, the test families and the test packages available for export are displayed and the associated tests can be selected.

|

|

| FluxMotor – Motor Factory – GUI and workflows – Export area | |

| 1 | The test families, the test packages and the associated tests are available for export. |

| 2 | Once a test is selected, the corresponding settings and input parameters are displayed. |