Since version 2026, Flux 3D and Flux PEEC are no longer available.

Please use SimLab to create a new 3D project or to import an existing Flux 3D project.

Please use SimLab to create a new PEEC project (not possible to import an existing Flux PEEC project).

/!\ Documentation updates are in progress – some mentions of 3D may still appear.

3D Example: Non destructive testing (Technical paper)

Foreword

This paragraph is a summary of cases studied in the technical document: " Nondestructive testing ".

The files relating to the studied cases are available in the documentation directory of the Flux DVD.

Study carried out

The study proposed in the technical paper "Nondestructive testing" is the modeling of an eddy current inspection of a plate containing a flaw by means of a probe.

Studied NDT problem

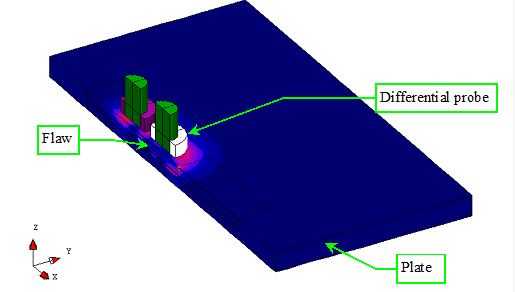

The device to be analyzed, presented in the figure below, consists of:

Operating principle

A block of inconel contains a flaw (represented in the figure above by a rectangular slot). A differential probe, composed by two active coils wounded in opposition, moves across the surface of the block. When these two coils are over a flaw-free area of the test sample, there is no differential signal developed between the coils since they are both inspecting identical material. However, when one coil is over a defect, a differential signal is produced.

Studied cases

The following cases are carried out with the Steady State AC Magnetic application:

- main case: an inspection of a plate containing a plane flaw with a differential probe

- appended cases:

- case 1: an inspection of a plate containing a crossing flaw with an absolute probe

- case 2: a Benchmark problem 8

- case 3: a tube inspection with a differential bobbin coil

- case 4: an inspection of a plate containing a triangular flaw with an absolute probe

Main case

The main case is an EC inspection of a plate with a plane flaw by means of a differential probe

This study describes the modeling of an eddy current inspection of a plate containing a plane parallel internal flaw with a differential probe made of 2 coils with a cylindrical ferrite core.

Appended case 1

The first case is an EC inspection of a plate with a crossing flaw by means of an absolute probe

This study describes the modeling of an eddy current inspection of a plate containing a crossing flaw with an absolute probe.

The second case is a Benchmark problem 8.

This study is an international benchmark problem – TEAM WORKSHOP Problem 8 – that describes the modeling of an eddy current inspection of a plate containing a thin internal flaw with a differential probe made with separated functions.

Appended case 3

The third case is an EC inspection of a tube with a plane flaw by means of a differential bobbin coil

This study describes the modeling of an eddy current inspection of a tube containing an internal plane parallel flaw with a differential bobbin coil.

Appended case 4

The forth case is an EC inspection of a plate with a triangular flaw by means of an absolute probe

This study describes the modeling of an eddy current inspection of a plate containing an internal triangular flaw with an absolute probe.