Low Pressure Process

Define the parameters for a low pressure die casting process.

Location: High Pressure is an option on the Basic Setup icon on the Casting ribbon

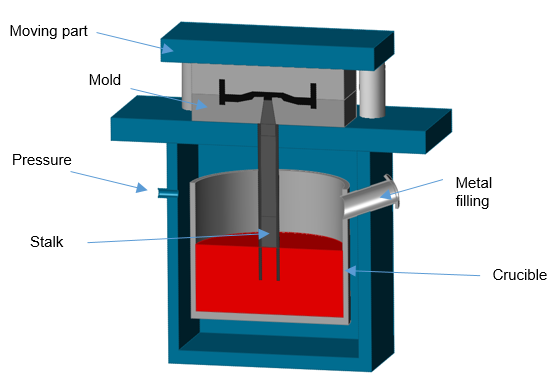

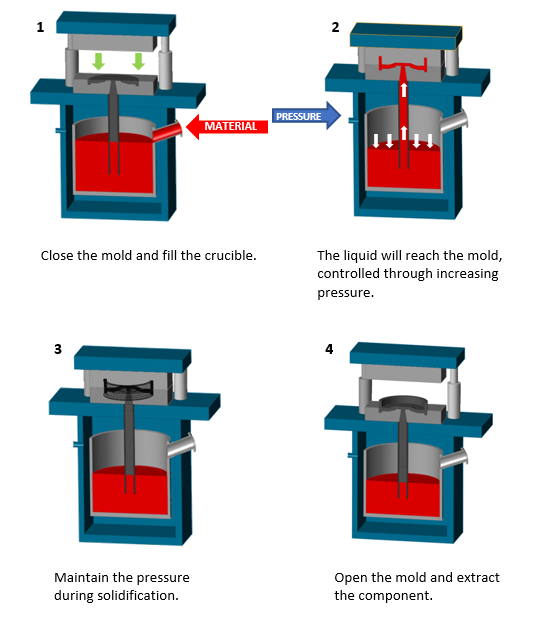

Low pressure die casting is a metal casting process generally used in situations that require high-quality manufacturing. In low pressure casting, molten aluminum is slowly drawn into a metal mold or die through a riser tube while kept under constant and controlled pressure. This process helps avoid oxidation, cold shuts, and air inclusions, generally producing excellent surface finish and highly accurate dimensions. However, it is much slower and therefore more costly than high pressure die casting.

Define Low Pressure Parameters

-

Click

next to the

Basic Setup icon, then select Low Pressure.

next to the

Basic Setup icon, then select Low Pressure.

- Optional:

Click Create Stalk and use the Add/Edit Stalk tool to create

and define the stalk.

- Enter values for Time and Pressure in the Pressure/Time Table.

Low Pressure Options

- Distance

- Enter the distance between the free surface in the crucible and the mold

(gate). This value must be > 0.

Note:

Enter pressure curve values in Mbar.