Make Board Paneling Tutorial

Make Board Paneling is a function to modify the data designed with a single sub board into an array type to use manufacturing related features such as Metal Mask Manager, Mounting Emulator, Block JIG Generator, Router-Machine JIG Generator, and so on.

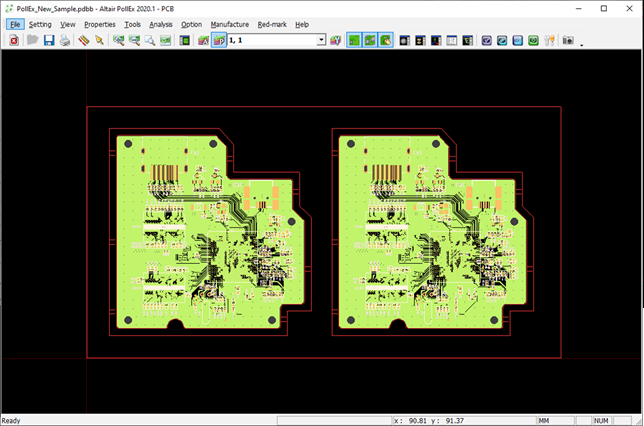

Make Board Paneling using PDBB

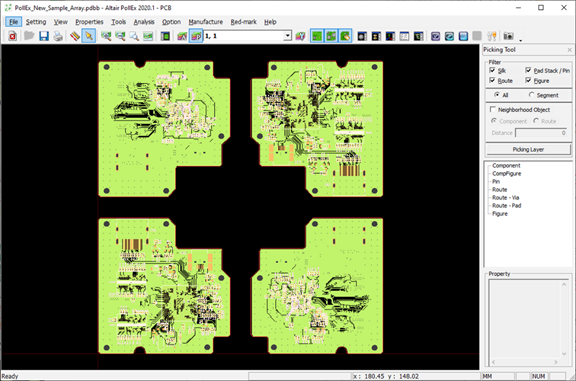

- Launch PollEx PCB.

- From the menu bar, click and open the PollEx_PCB_Sample_r<revision number>.pdbb file from C:\ProgramData\altair\PollEx\<version>\Examples.

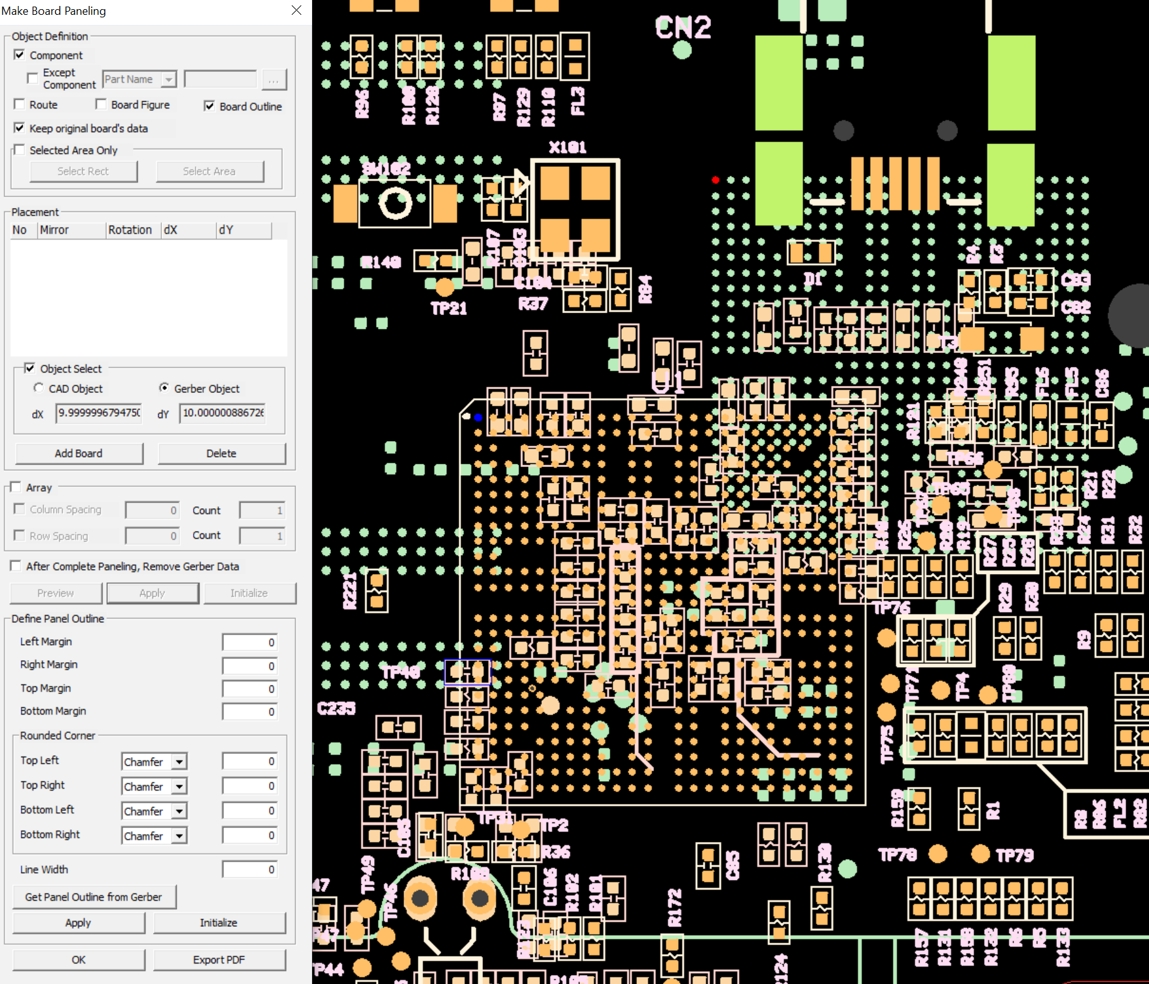

- From the menu bar, click to open the Make Board Paneling dialog.

-

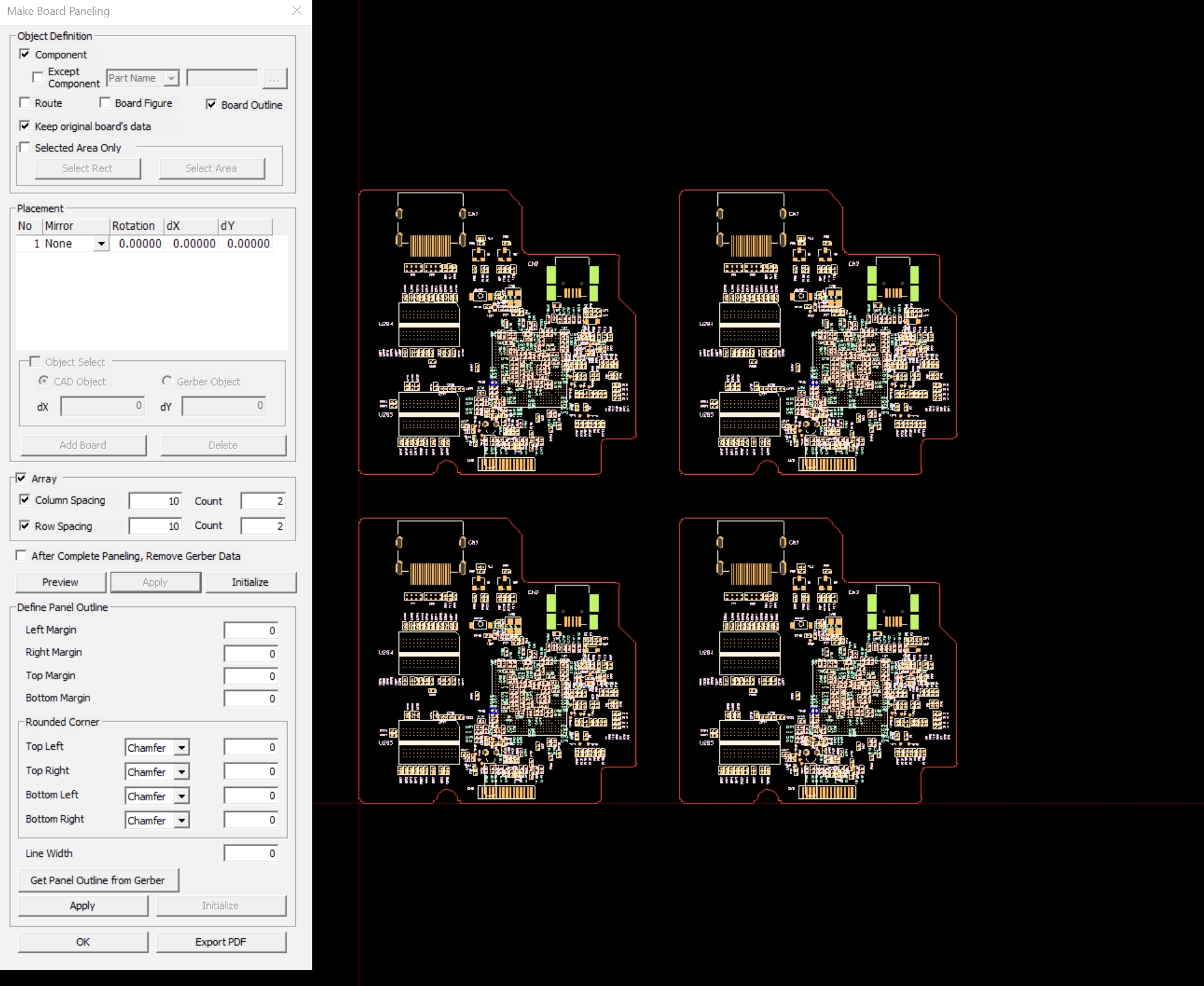

Create array.

- In the Make Board Paneling dialog, enable the Route checkbox.

- Enable the Board Figure checkbox.

- Enable the Board Outline checkbox.

- Click Add Board four times to register a total of four lists in Placement.

Note: A total of four lists, from No.1 to No.4, are created in Placement. -

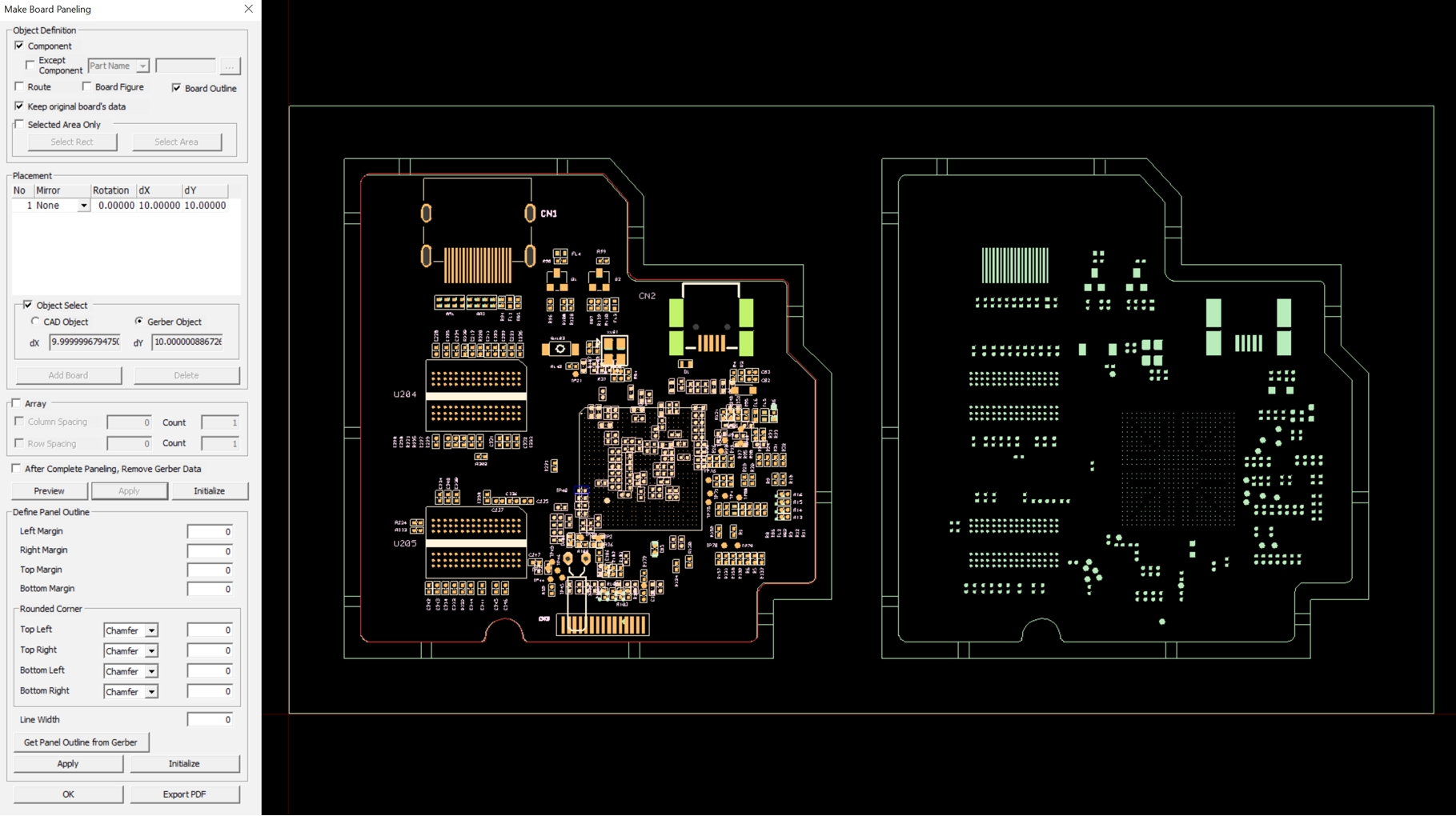

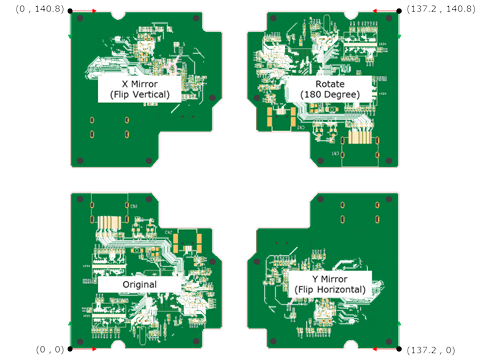

Set Array Placement No2.

- Select Y Mirror.

- Under Placement, enter 137.2 for dX and 0 for dY.

-

Set Array Placement No3.

- Select X Mirror.

- Under Placement, enter 0 for dX and 140.8 for dY.

-

Set Array Placement No4.

- For Rotation Angle, enter 180.

- Under Placement, enter 137.2 for dX and 140.8 for dY.

- Click Apply.

Note: The original data is copied and arranged as registered in the Array list..jpg)

-

Create Array.

- Select Column Spacing and Row Spacing under Array, then enter 10.

- Enter 2 for Count.

- Click Apply.

-

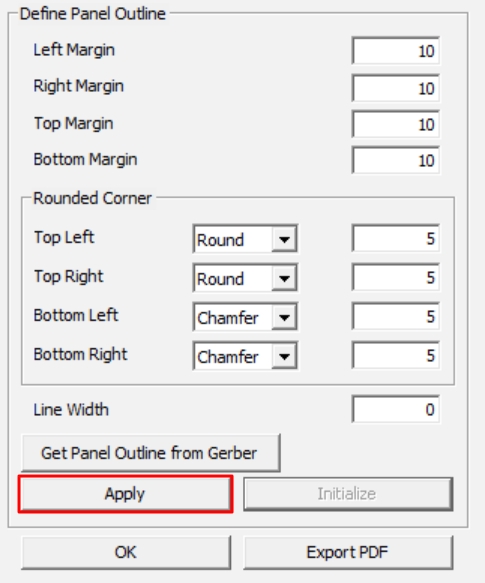

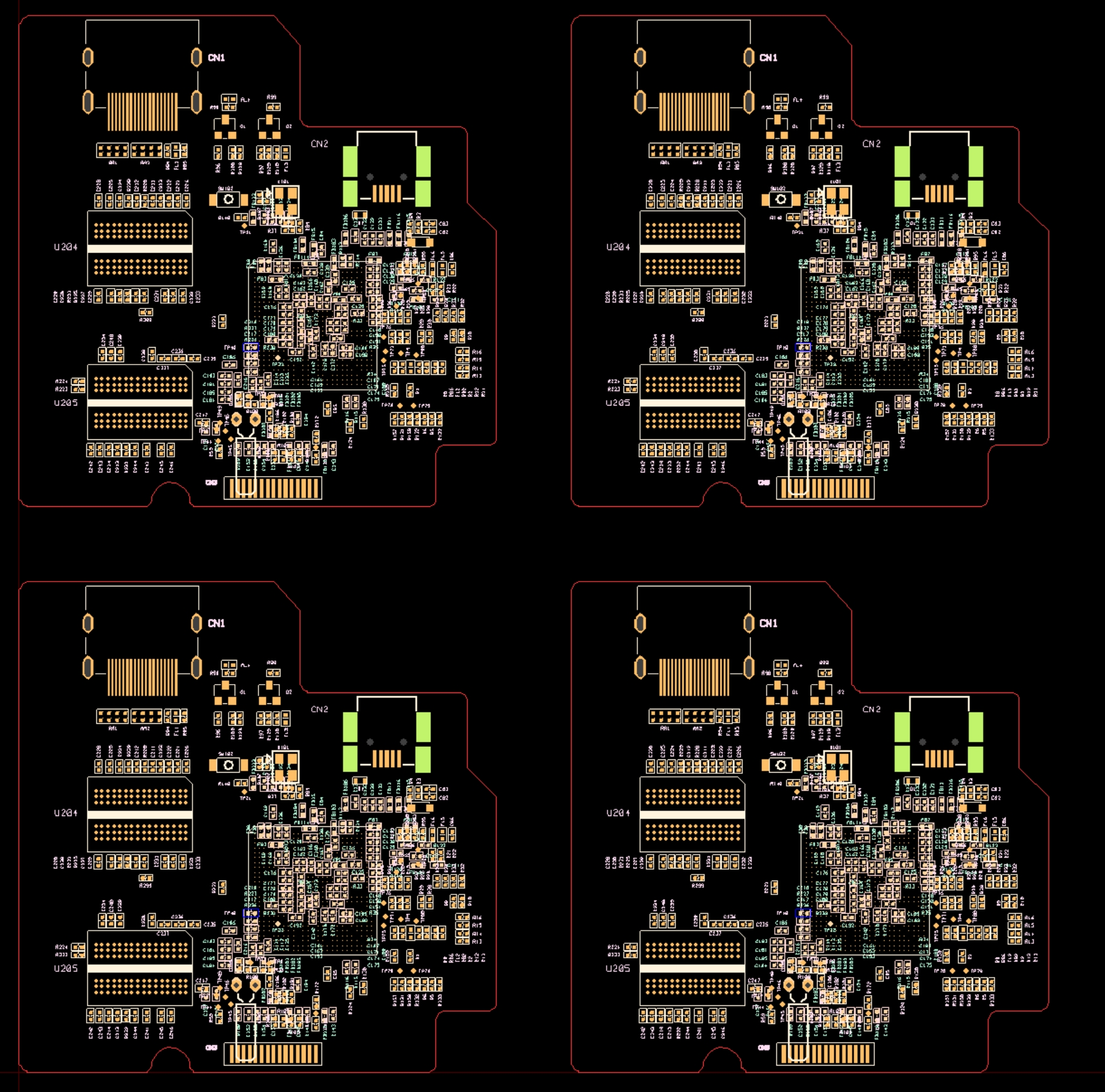

Create Panel Outline.

Make Board Paneling using Gerber Data

- Launch PollEx PCB.

- From the menu bar, click and open the PollEx_PCB_Sample_r<revision number>.pdbb file from C:\ProgramData\altair\PollEx\<version>\Examples.

-

Import Gerber data.

When the Metal Mask Gerber of the panel board is prepared, the sub-boards can be automatically calculated by selecting the component pad of the design data and the pad object of the Gerber data.

- From the menu bar, click . to open the Import from Gerber (RS-274D/RS-274X) dialog.

-

In the Import from Gerber (RS-274D/RS-274X)

dialog, click

.

.

- Select all Top-Metal files from C:\ProgramData\altair\PollEx\<version>\Examples\MFG\Data\MetalMaskGerber.

-

From the tool bar, click

to

disable routing data.

to

disable routing data.

- From the menu bar, click to open the Make Board Paneling dialog.

-

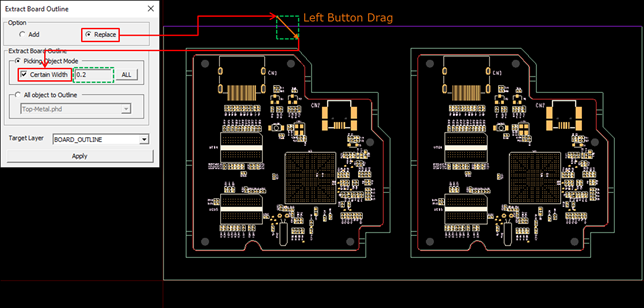

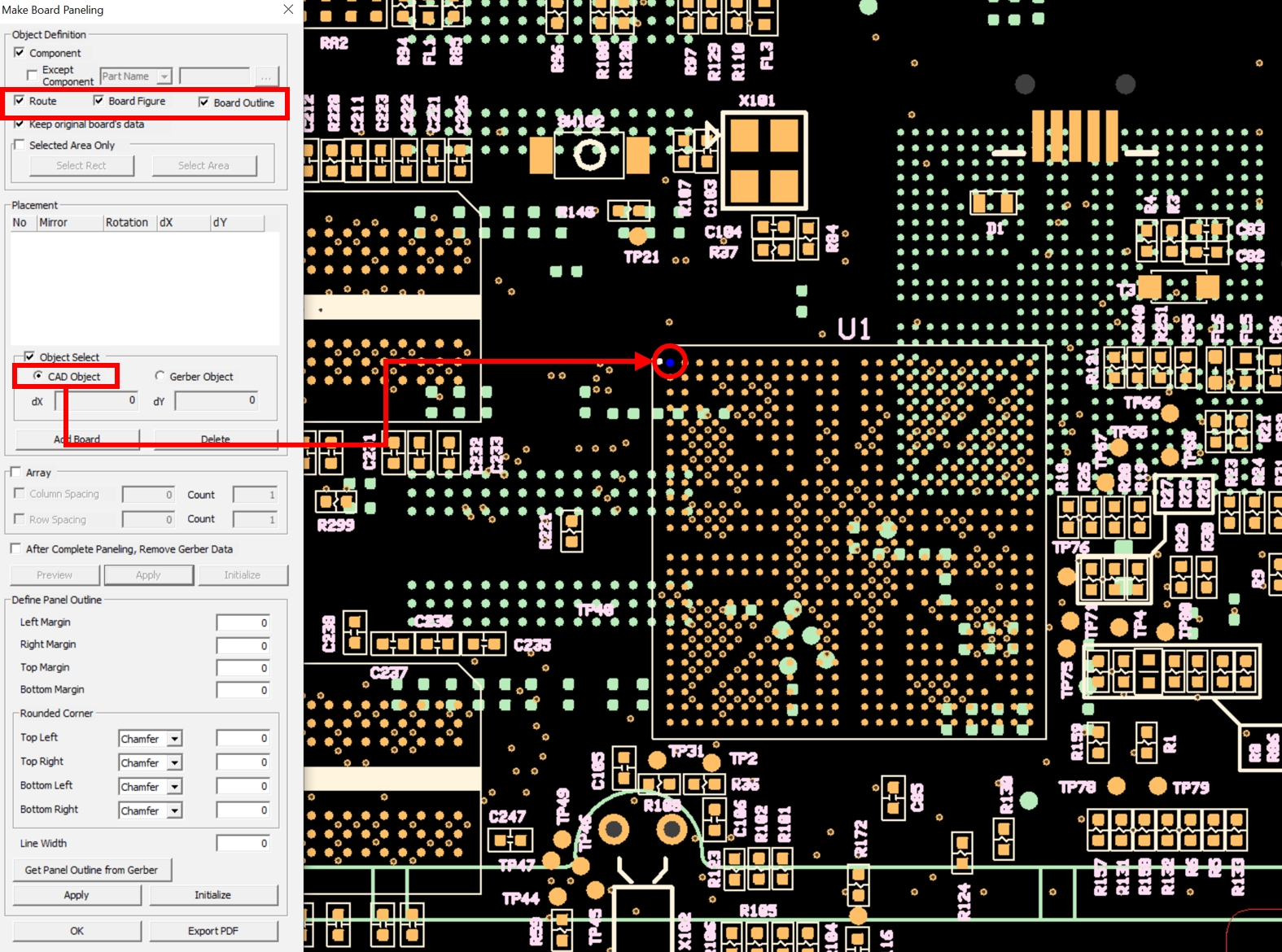

Create Array List by selecting CAD and Gerber data.

- In the Object Definition section of the Make Board Paneling dialog, enable the following checkboxes: Route, Board Figure, and Board Outline.

- In the Object Select checkbox and select CAD Object.

- Select the Pad to be used as the reference from the CAD data.

Figure 2.

-

Select pad based on Gerber data.

-

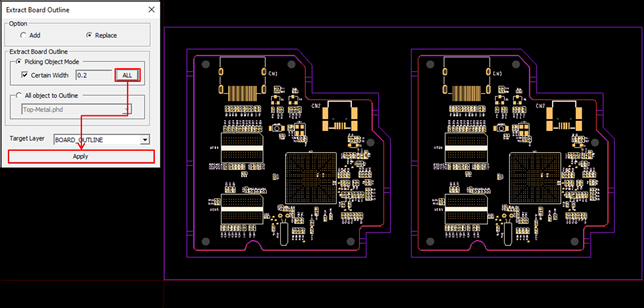

Create Panel outline.

Use the Get Panel Outline from Gerber option to define the Panel Outline.

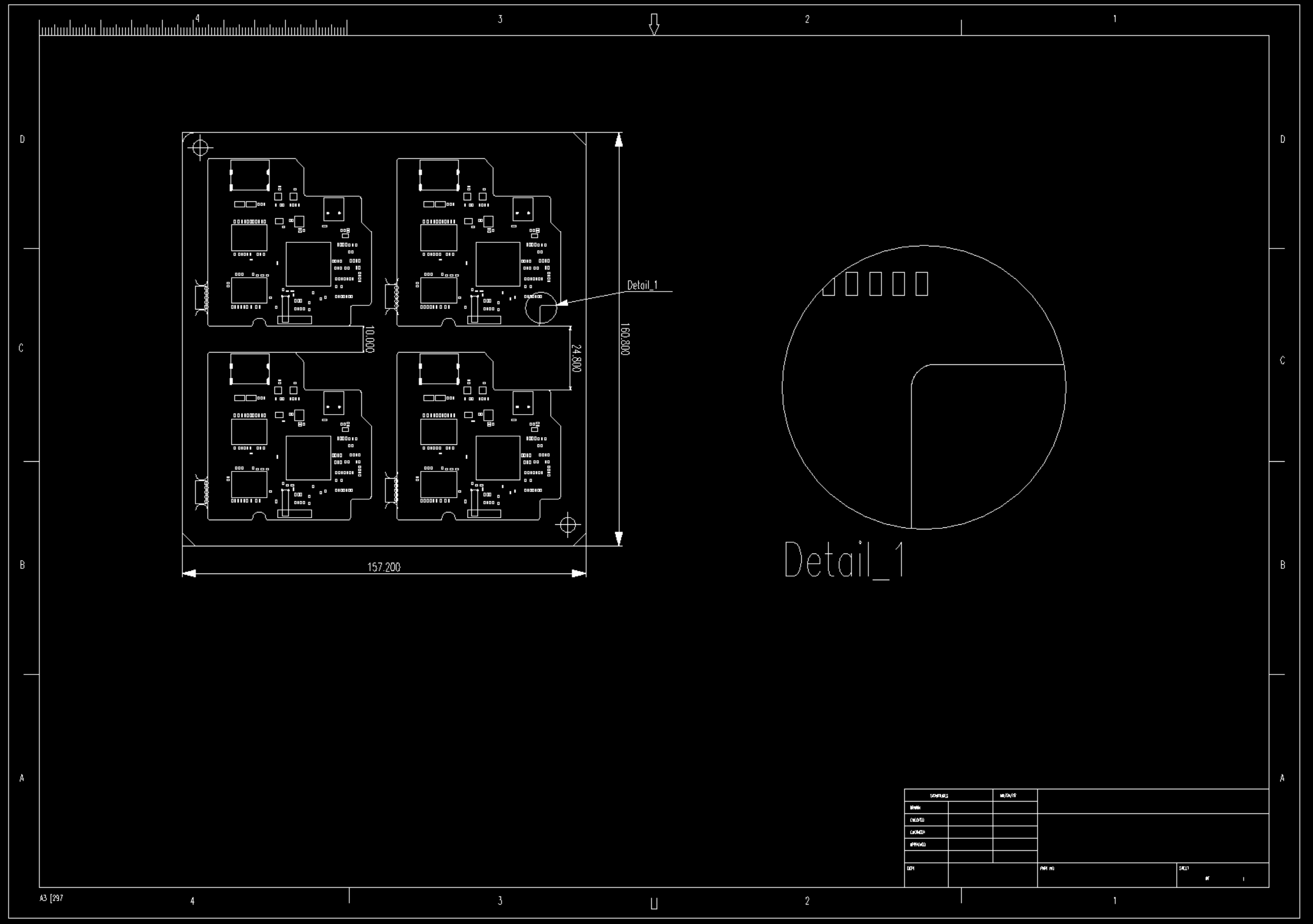

Make Board Paneling - Export PDF

- Launch PollEx PCB.

- From the menu bar, click and open the PollEx_PCB_Sample_r<revision number>.pdbb file from C:\ProgramData\altair\PollEx\<version>\Examples.

- From the menu bar, click .

-

Create Array.

-

Create Panel Outline.

In the Define Panel Outline section, you can define the Panel Board outline.

-

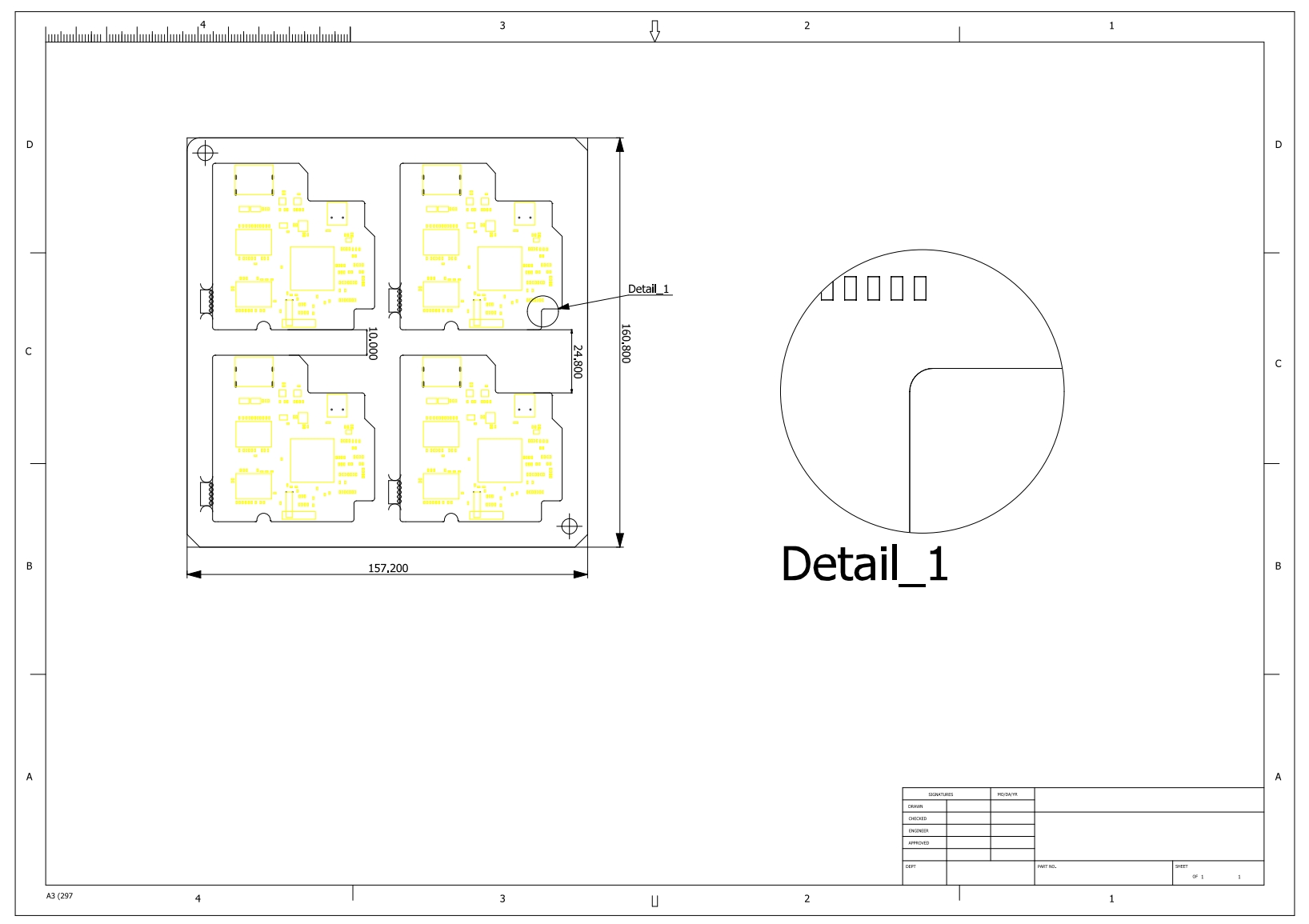

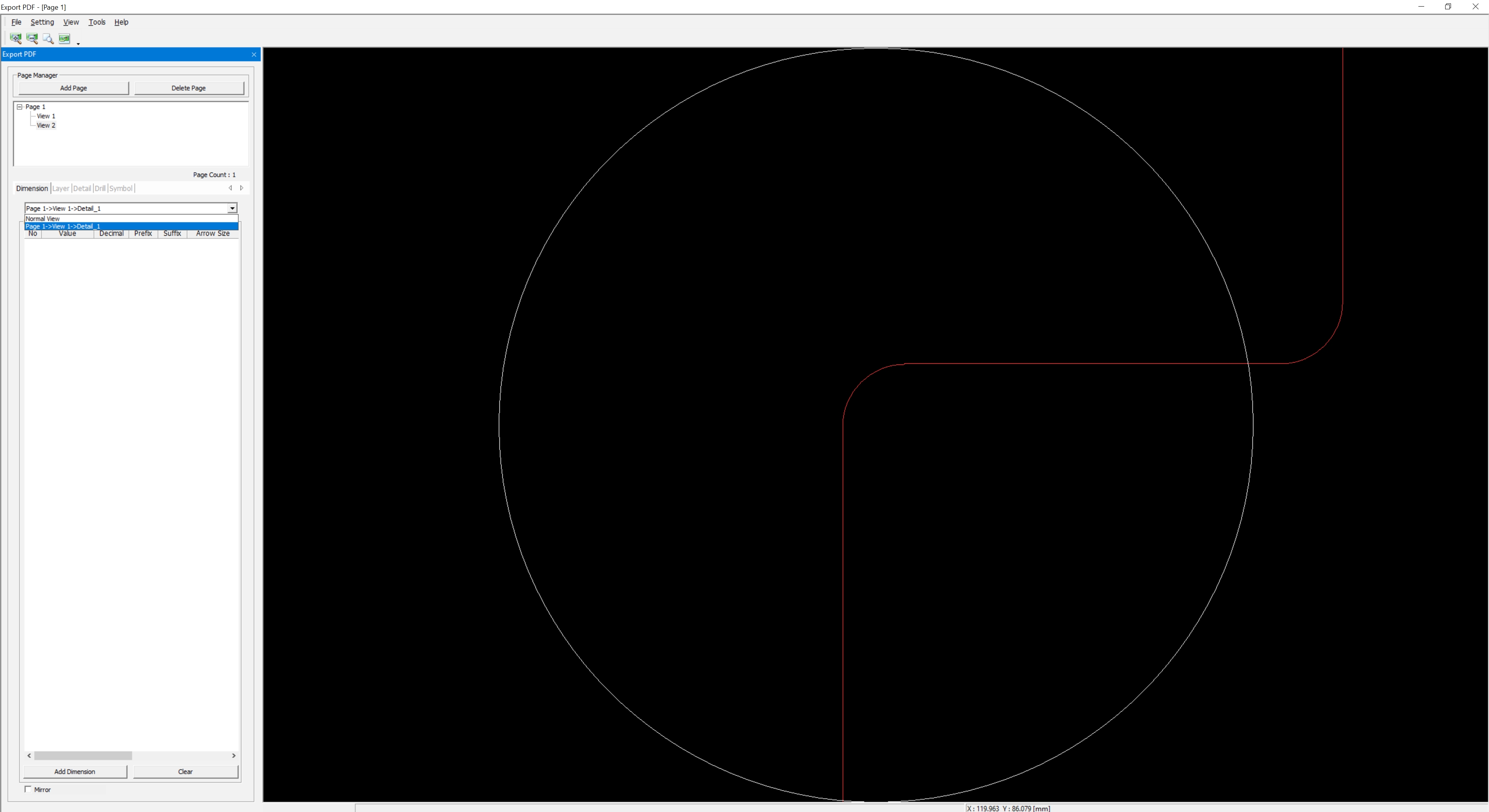

Export PDF.

-

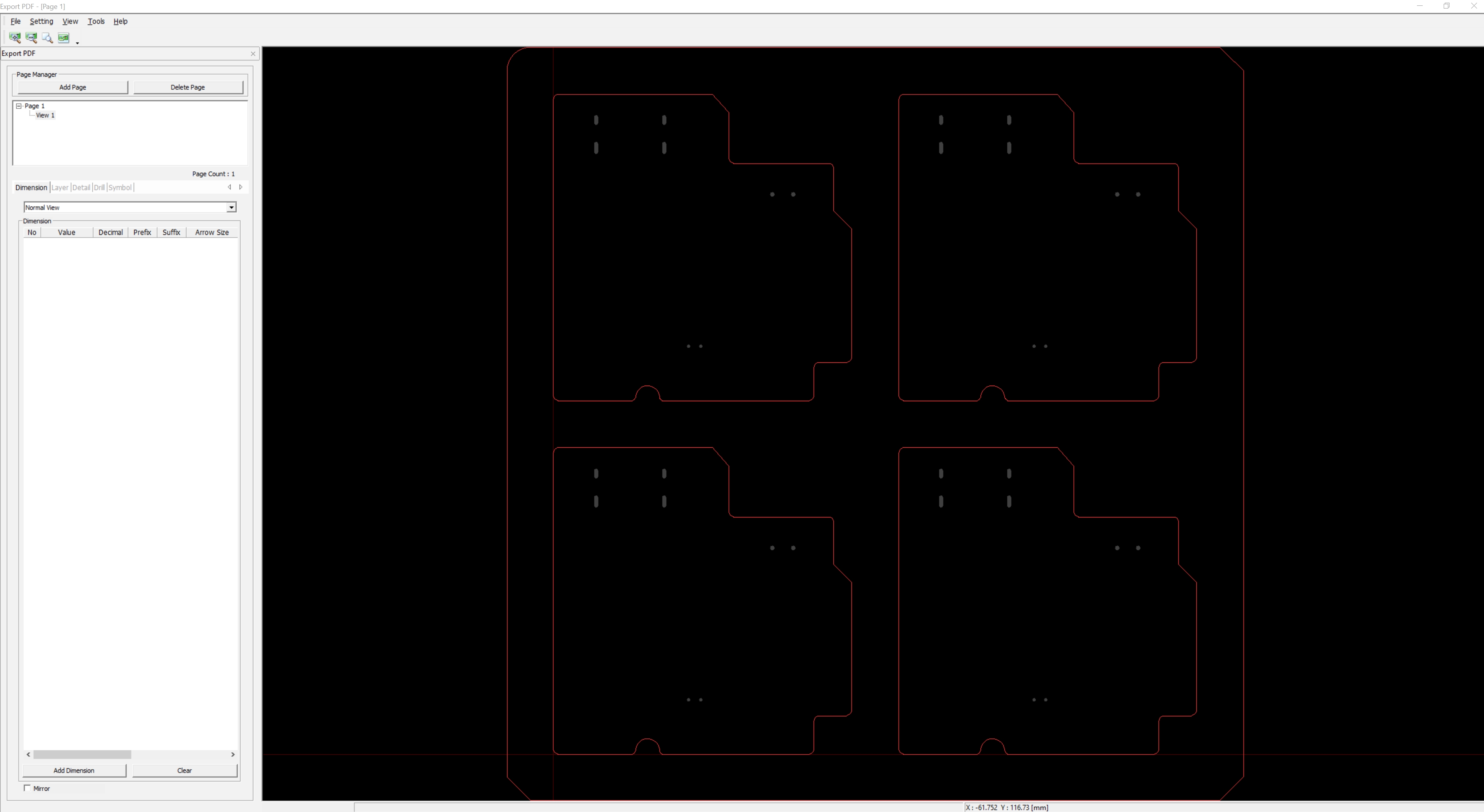

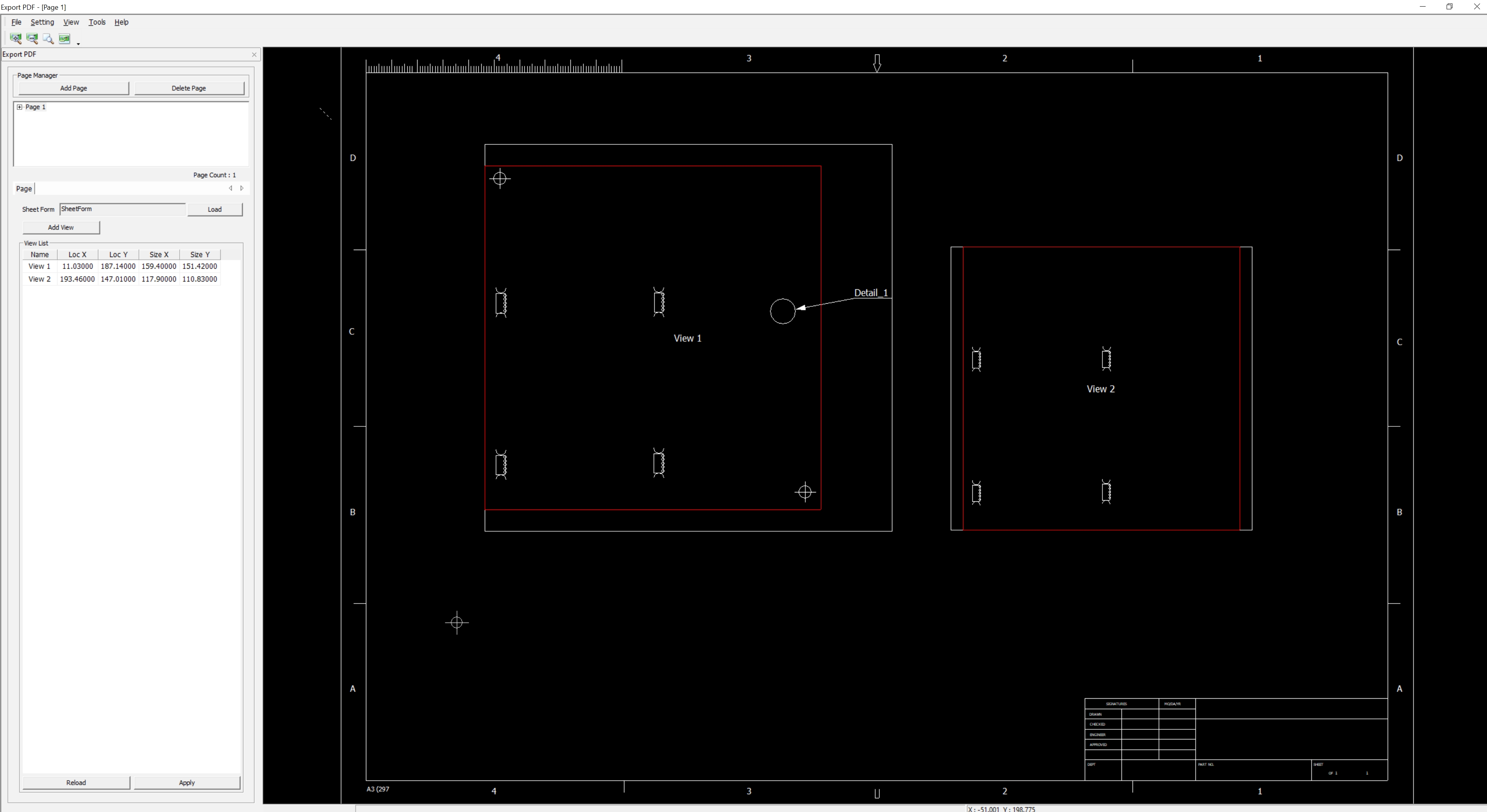

Add Paneling Board View.

-

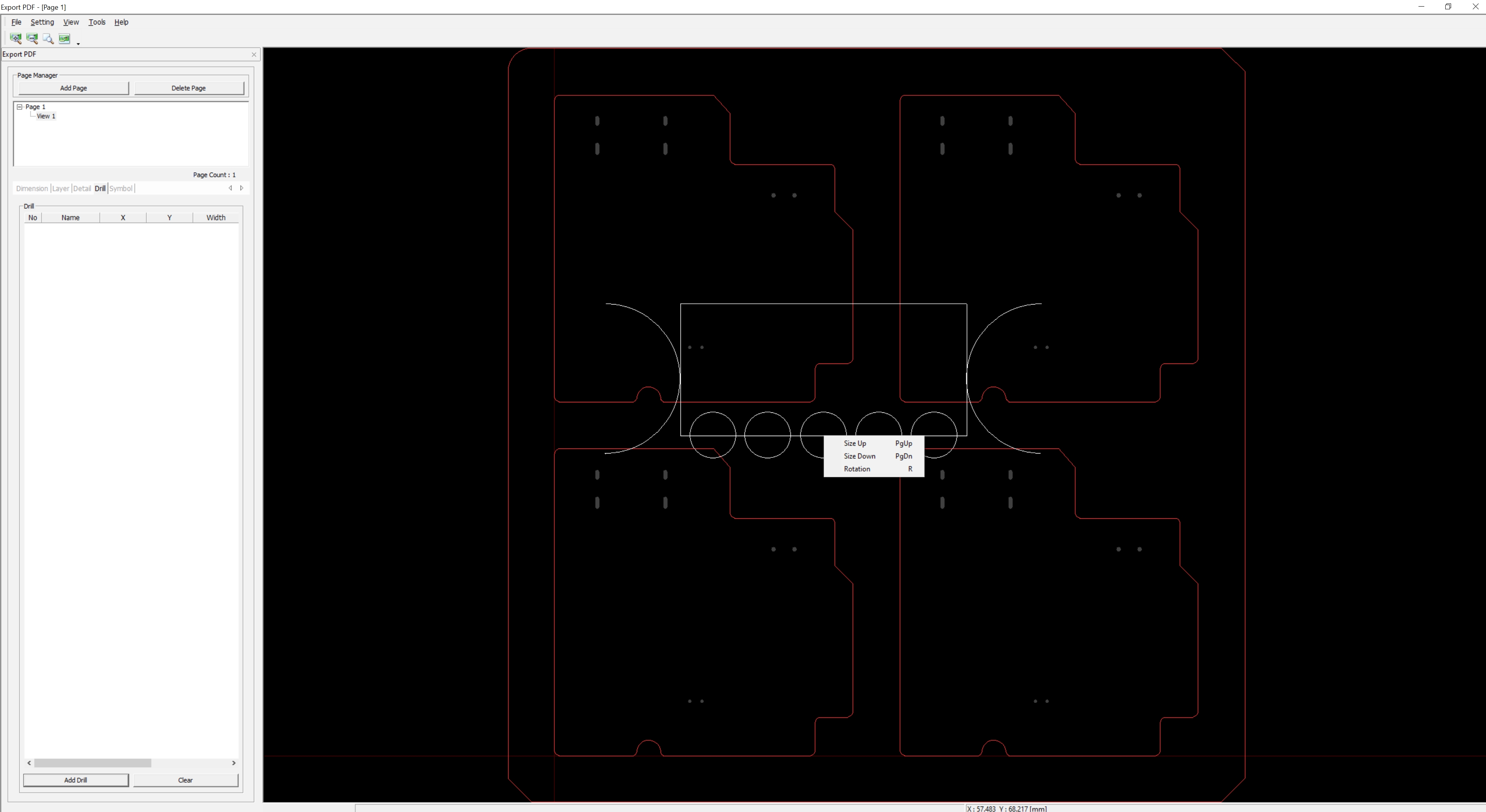

Add Drill.

-

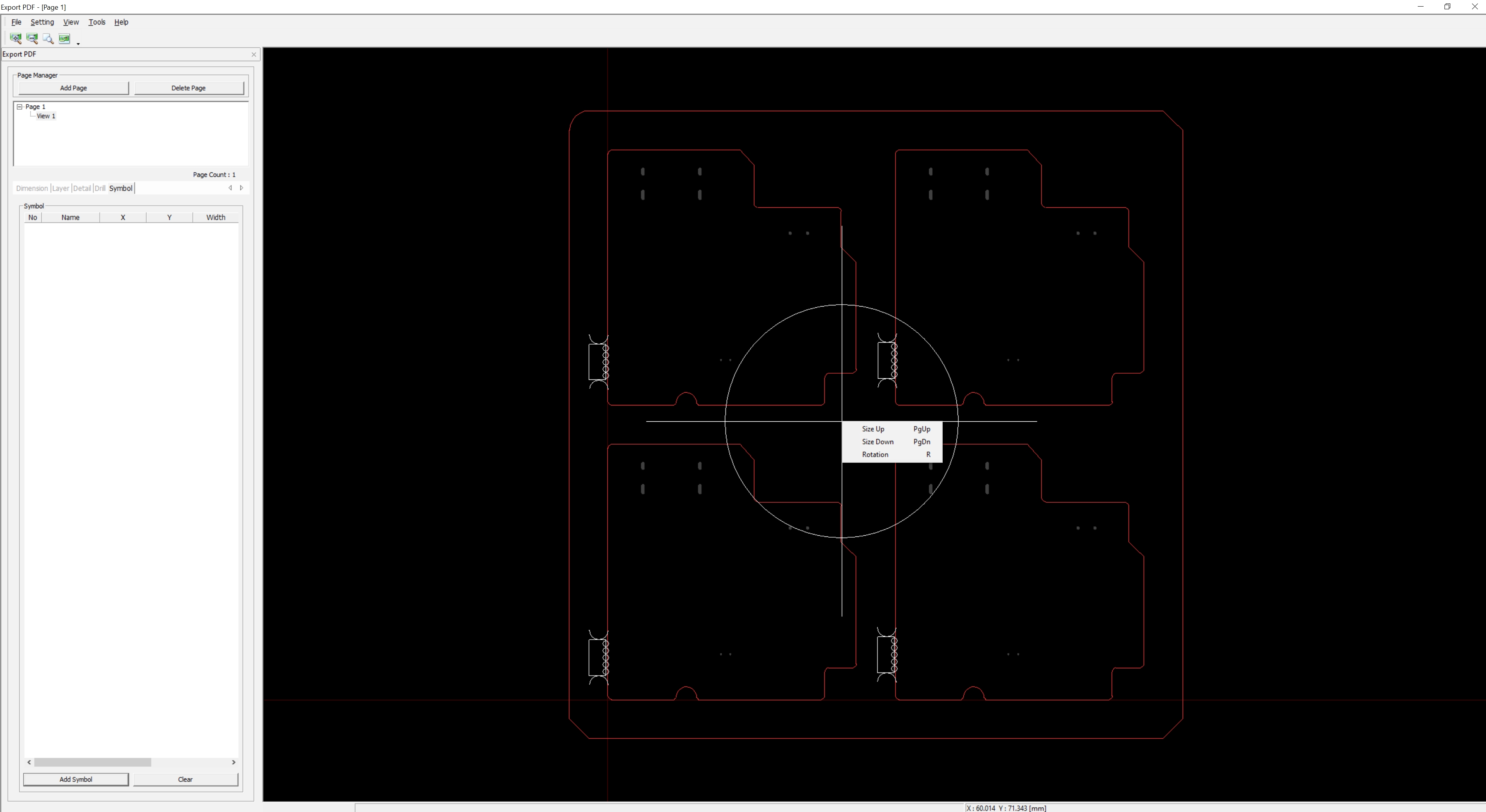

Add Symbol.

-

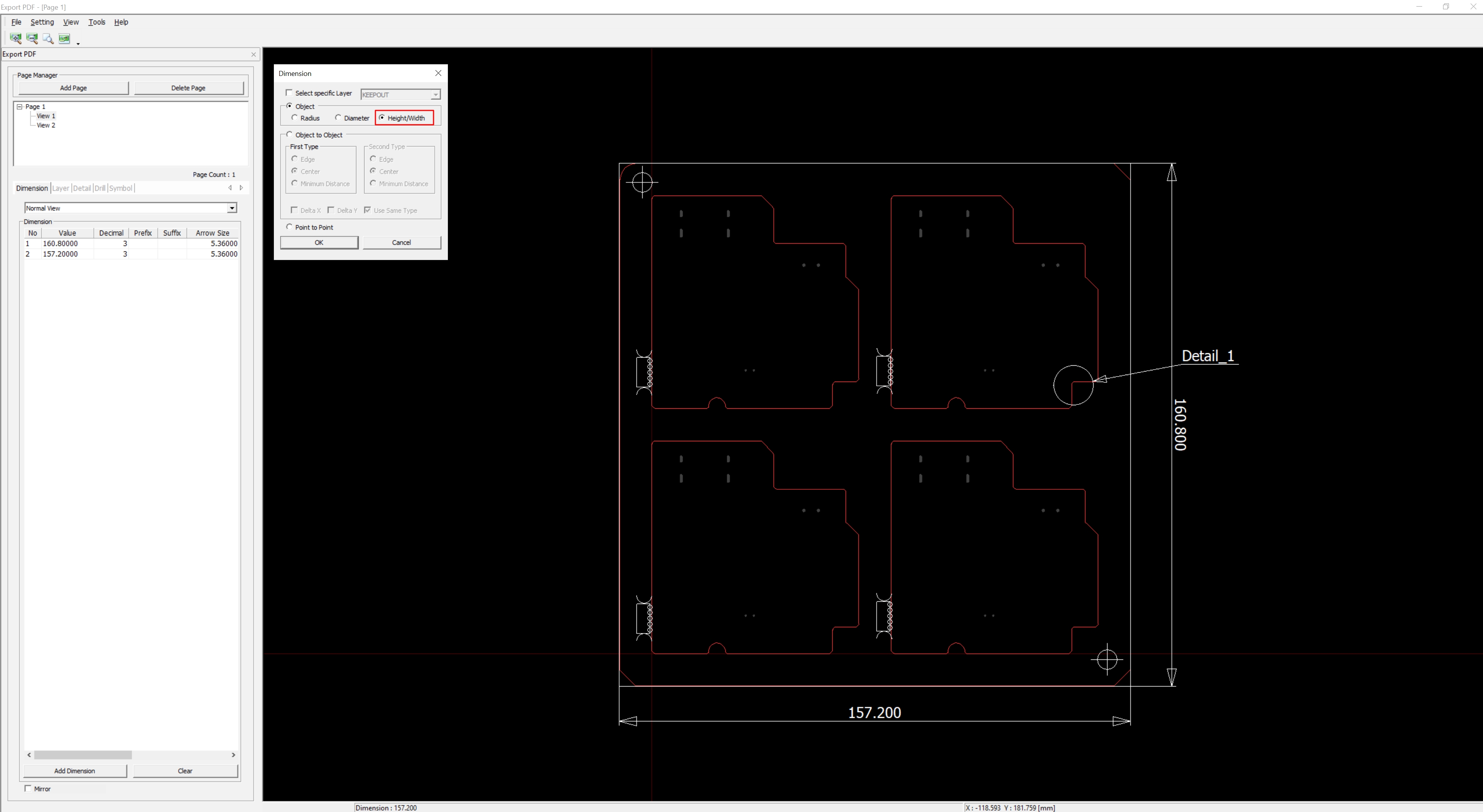

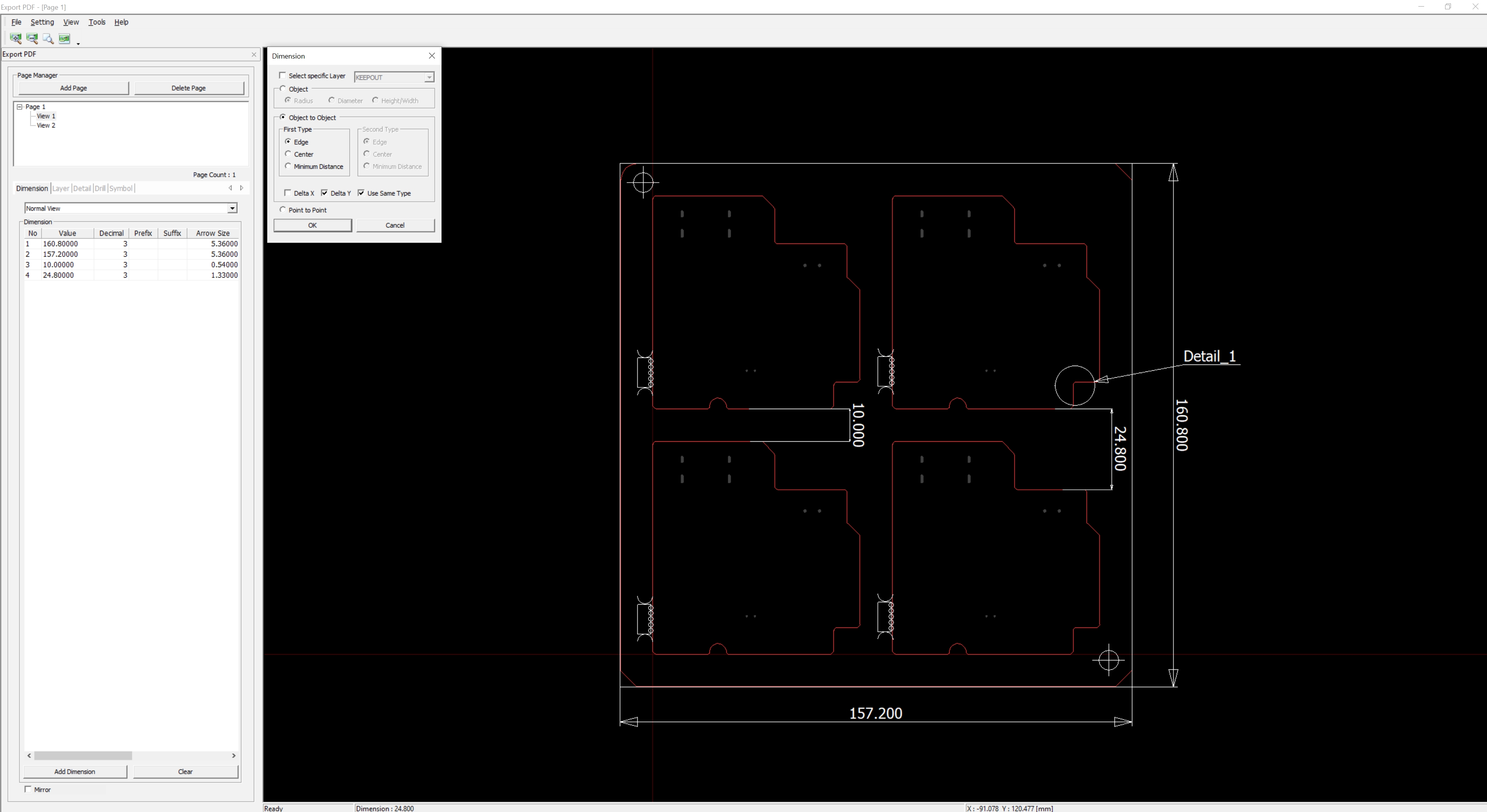

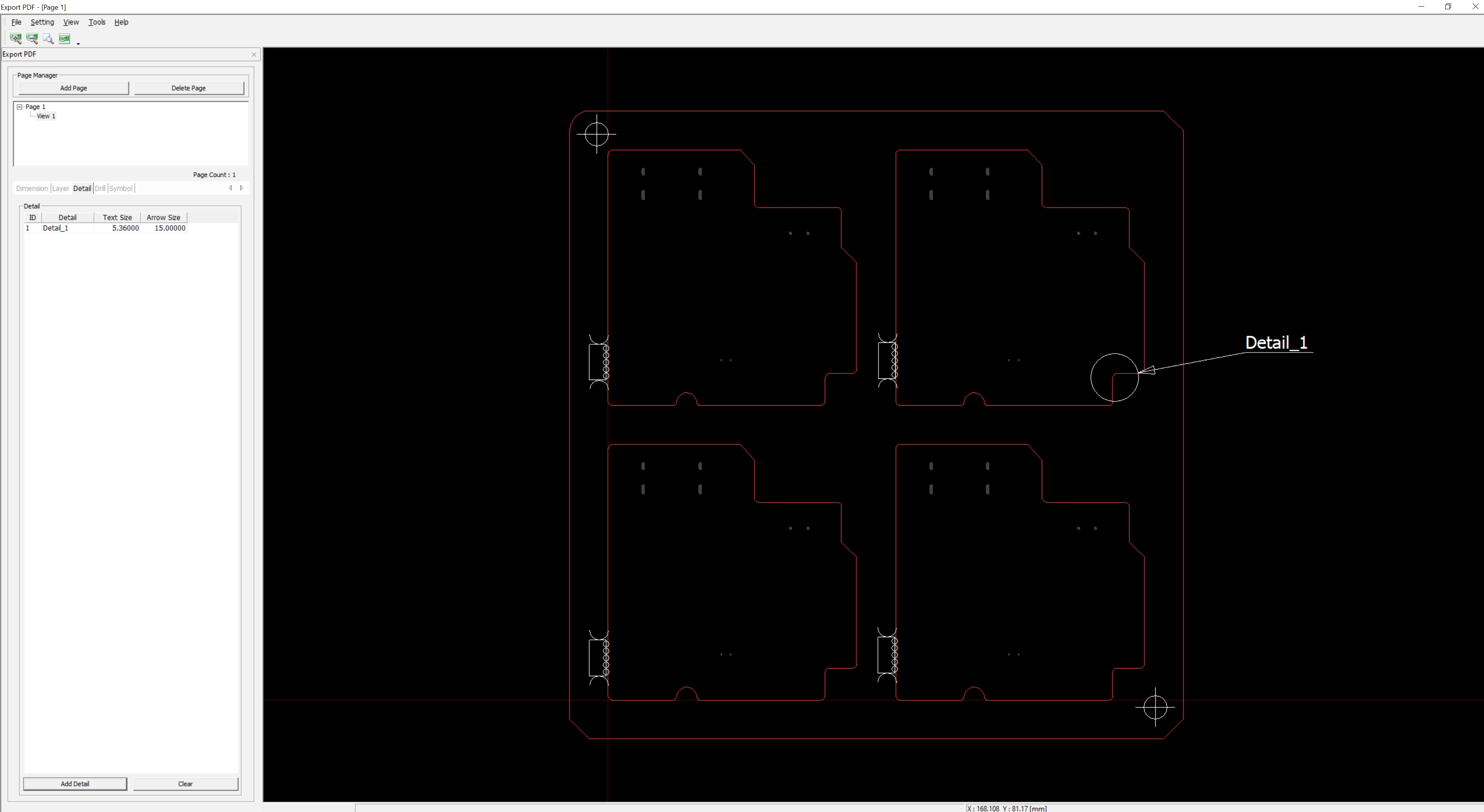

Add Detail.

- In the Detail tab, click the Add

Detail.

- In the Page tab, click the Add

View.

- In the View2, select in list.

- In the Detail tab, click the Add

Detail.

-

Add Dimension.

-

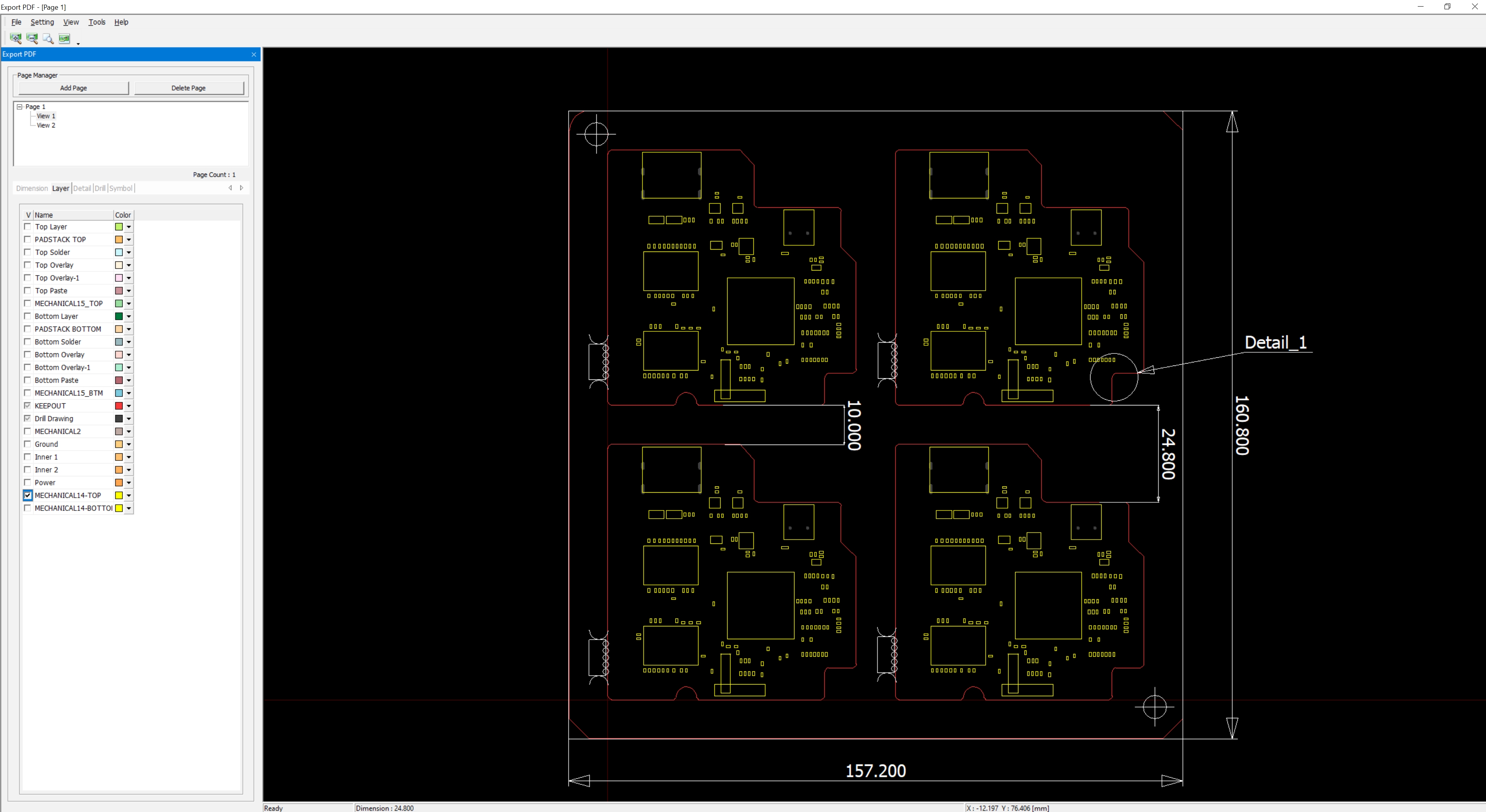

Layer Settings.

-

Save and Export PDF.

-

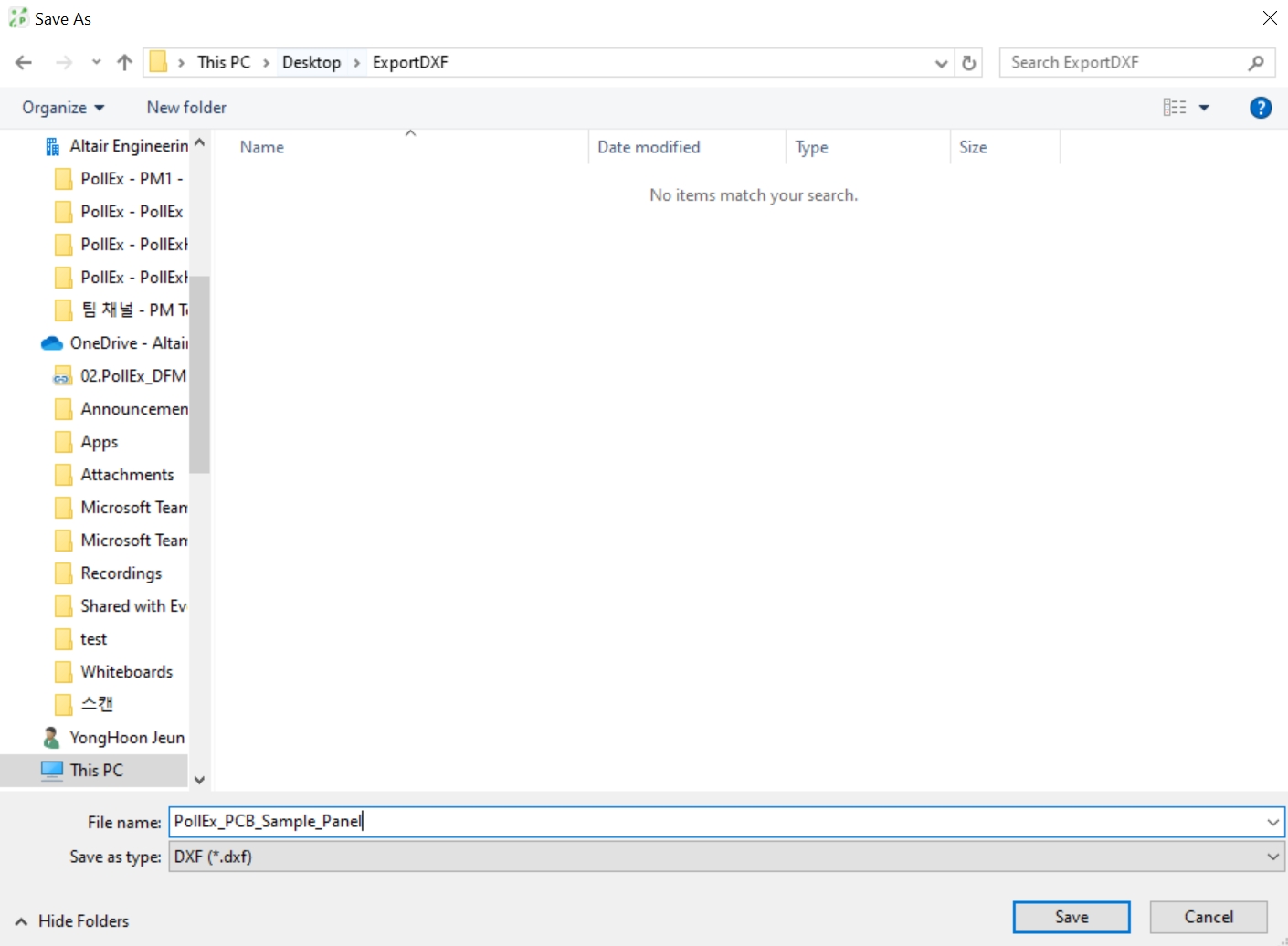

Save and Export DXF

- Save the created data as a *.dxf file.

Figure 24.

- Drag .dxf file on OpenCAD

Figure 25.

- Save the created data as a *.dxf file.