UPE Tutorial

PollEx UPE (Unified Part Editor) is a software for managing component 3D package geometry, footprint, logic symbol, signal integrity analysis model, and thermal analysis information.

Create New Part Automatically

-

Click UPE in the PollEx Launcher.

The main window displays.

-

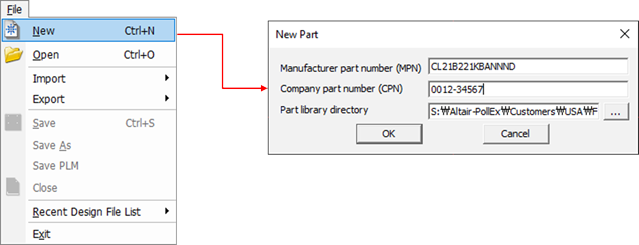

Create a new part.

- From the menu bar, click .

- Enter CL21B221KBANNND for the Manufacturer part number (MPN).

- Enter 0012-34567 for the Company part number (CPN) for the part.

Figure 1.

-

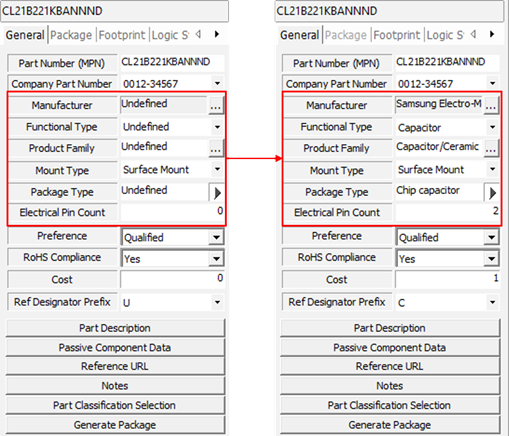

In the General tab, enter the component information.

- Set Function Type to Capacitor.

- Set Product Family to Capacitor/Ceramic.

- Set Package Type to Chip Capacitor.

- Set Electrical Pin Count to 2.

Function type, Product Family, Package Type, and Electrical Pint Count are mandatory.Figure 2.

-

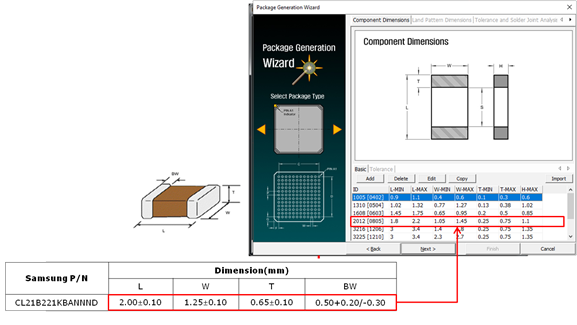

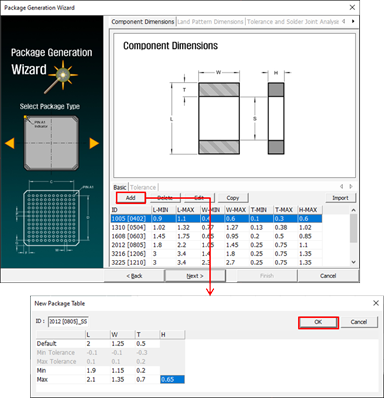

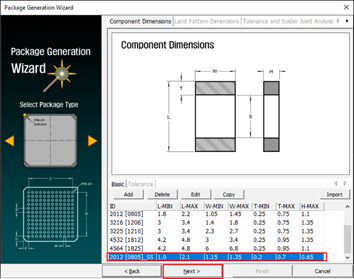

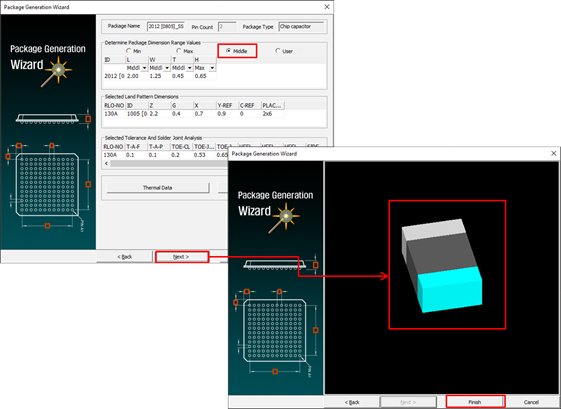

Generate a package using the package generation wizard.

-

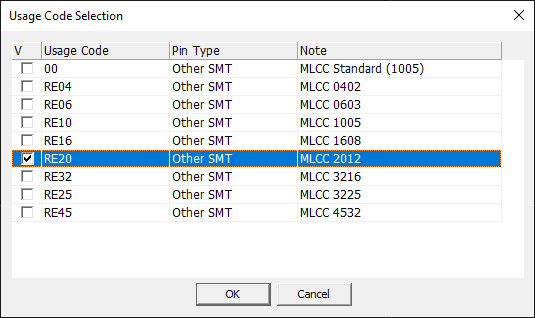

Generate a footprint automatically.

-

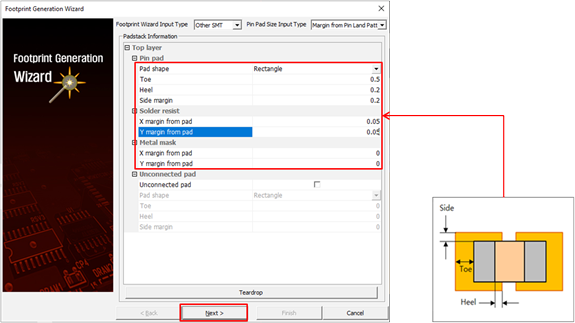

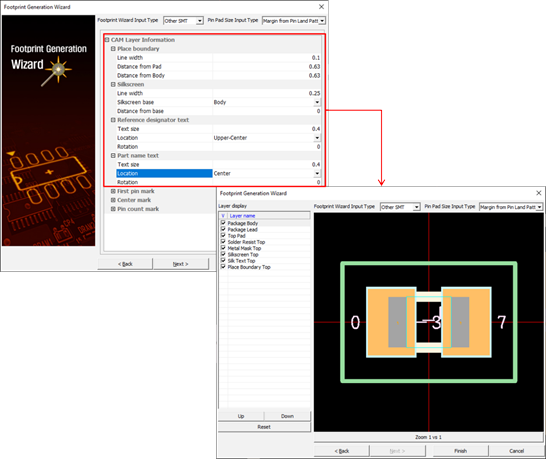

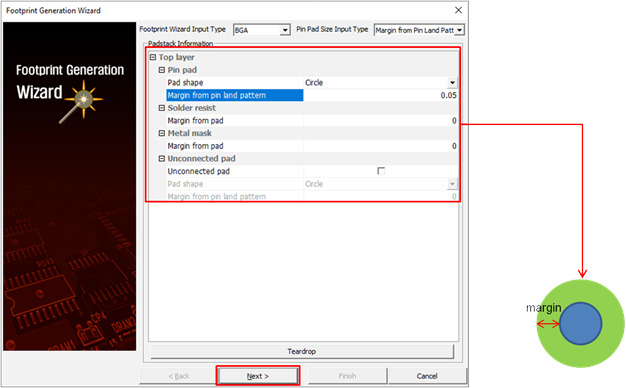

Generate a footprint using footprint generation wizard.

This is useful when there is no configuration for the package in the footprint configuration table, you cannot generate a footprint automatically.

-

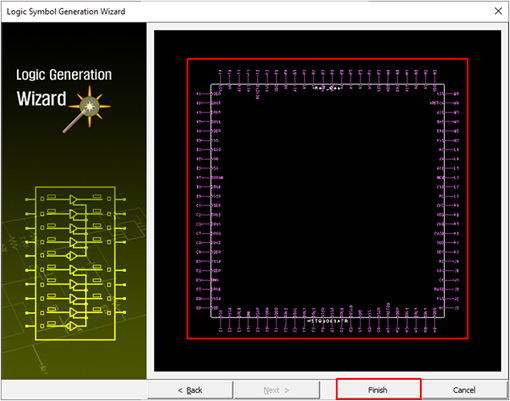

Generate a logic symbol automatically.

- Click the General tab to check the general information of the created part.

-

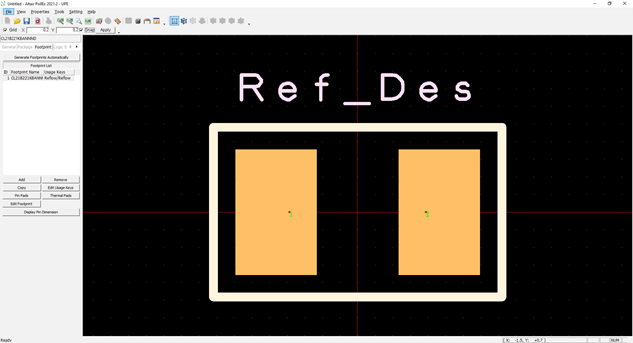

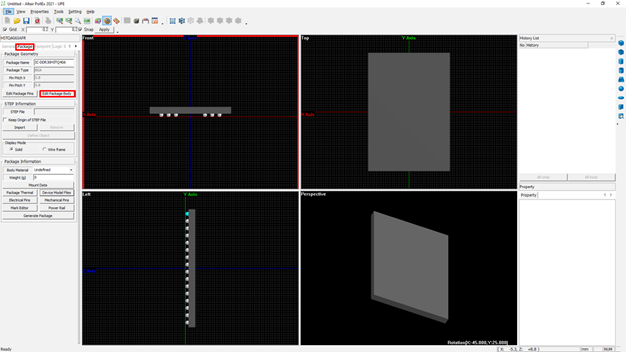

Check the package shape.

- Click the Footprint tab to check the footprint shape of the part.

- Click the Logic Symbol tab to check the logic symbol shape of the part.

Create New Part Manually

-

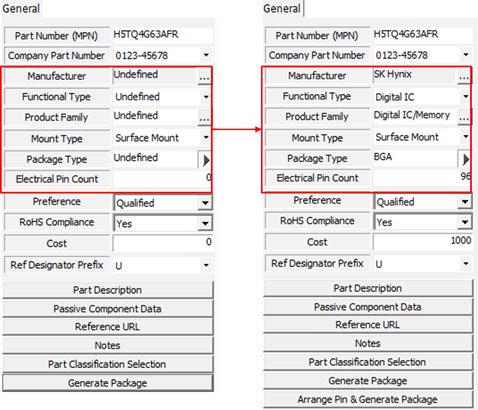

Create a new part.

- From the menu bar, click .

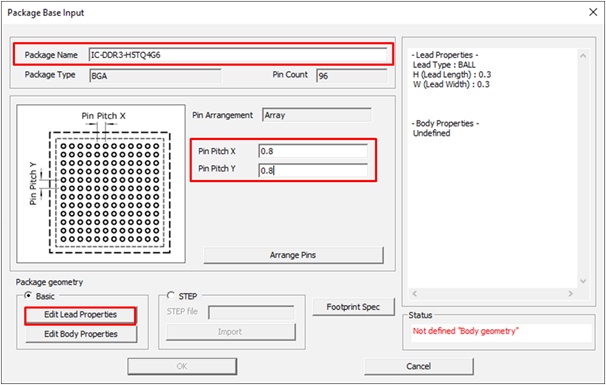

- Enter H5TQ4G63AFR for the Manufacturer part number (MPN).

- Enter 0123-45678 for the Company part number (CPN).

-

In the General tab, enter the component information.

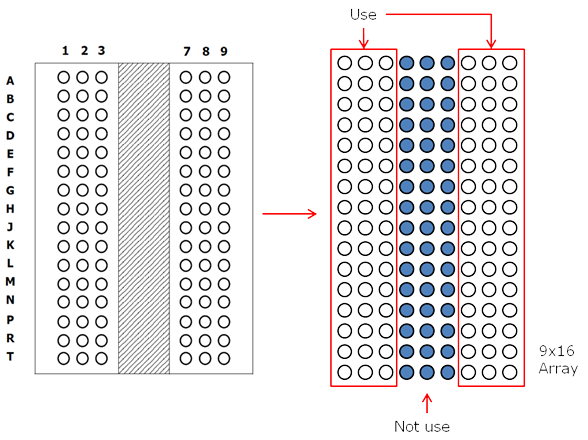

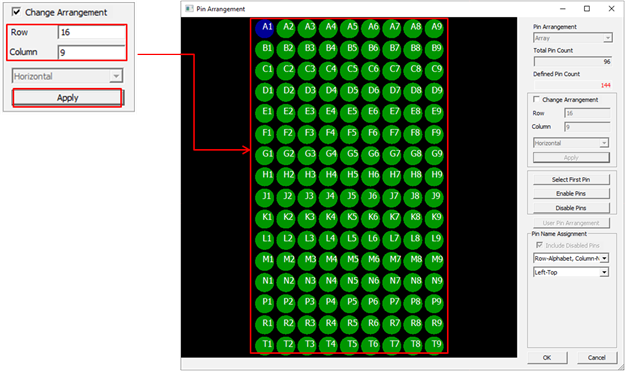

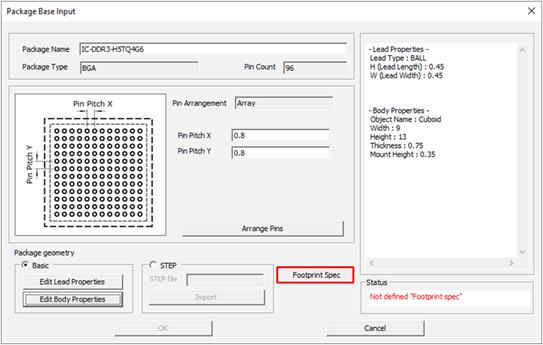

- For Package Type, select BGA.

- For Electrical Pin Count, enter 96.

Package Type and Electrical Pin Count are mandatory.Figure 12.

-

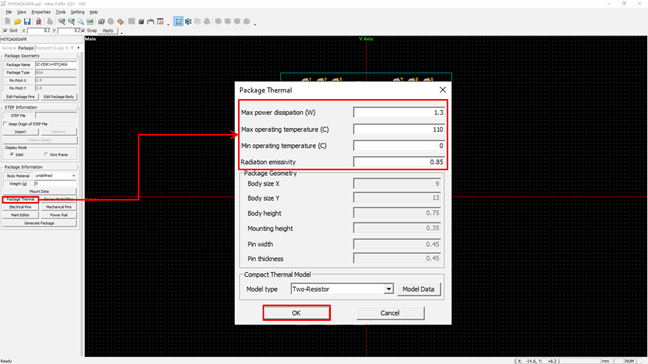

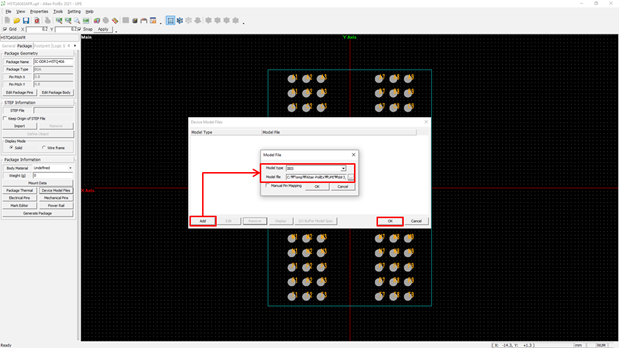

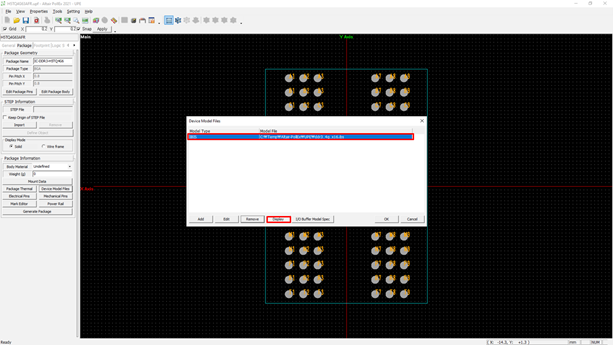

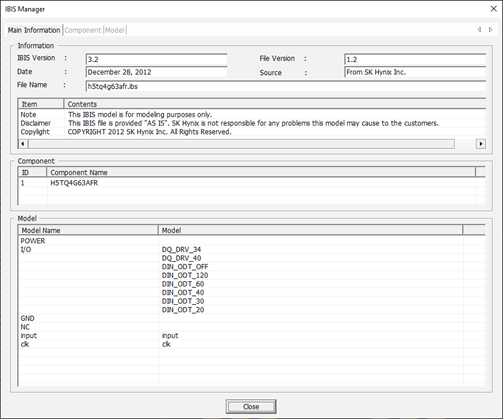

Arrange pins and generate package.

-

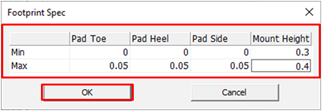

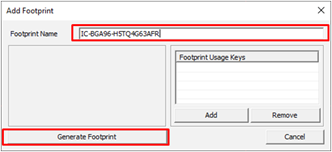

Generat a footprint.

-

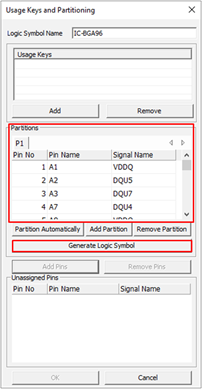

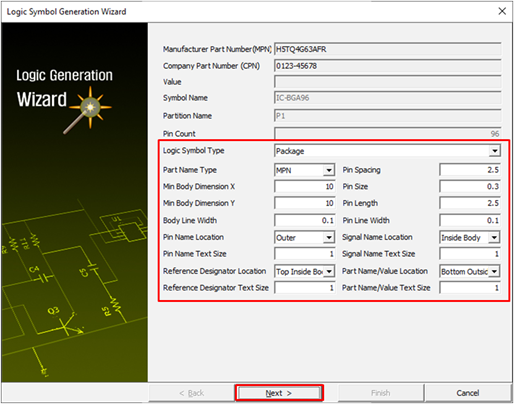

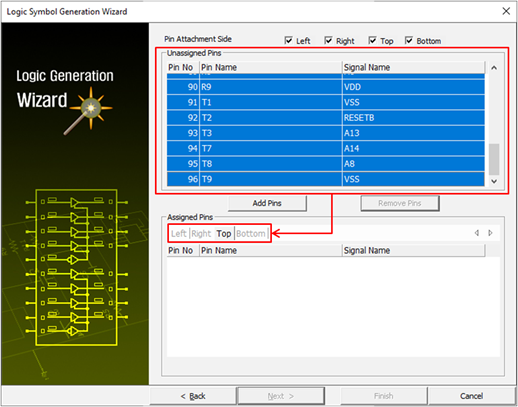

Generate a logic symbol.

- Click the General tab to check the general information of the part.

-

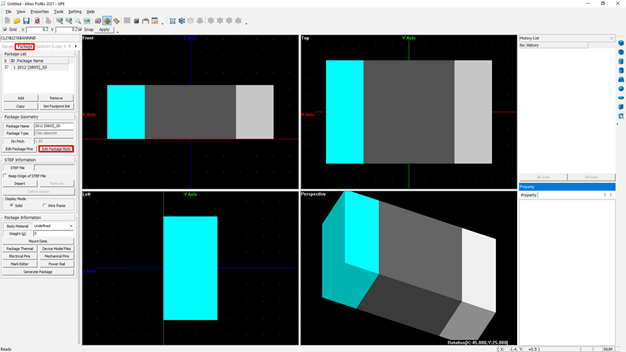

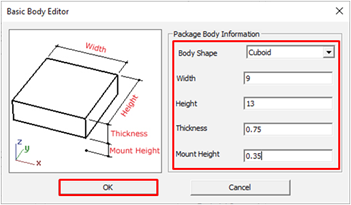

Click the Package tab and click Edit Package

Body to check the package shape of the part.

Figure 30.

- Click the Footprint tab to check the footprint shape of the part.

- Click the Logic Symbol tab to check the logic symbol shape of the part.