Hydraulic System Modeling

Learn about modeling hydraulic systems with the Hydraulics library (HydraulicsByFluidon).

Hydraulics (By Fluidon)

Twin Activate facilitates hydraulic system modeling through the Hydraulics (By Fluidon) block library.

Hydraulics (By Fluidon) is a Modelica library for the one-dimensional simulation of fluid-power systems. Models created with the Hydraulics (By Fluidon) library are based on the lumped parameter approach. The library consists of various hydraulic components and predefined hydraulic fluids.

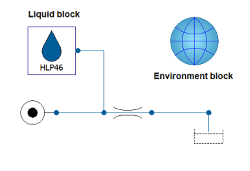

Basic Diagram of a Hydraulic System

When modeling a hydraulics system in Twin Activate, two blocks are required from the Hydraulics (By Fluidon) library: the Liquid block and Environment block.

The Environment block includes information about the environmental conditions, for example, the ambient pressure or the value of the gravitational constant. The Liquid block determines the hydraulic fluid that is used, which is why every hydraulic component in a model must be connected to it. In order to save you the trouble of connecting the liquid block to each component manually, the option forwardFluidProperties is included in certain components. With this option, you connect the liquid block to each hydraulic circuit only once since the fluid information is forwarded between the components.

Fundamentals of the Lumped Parameter Approach

In hydraulic engineering, the lumped parameter approach assumes that the state of a cross-section within a hydraulic system is fully described by flow rate and pressure. Due to numerical limitations, the application of the lumped parameter approach is usually restricted to systems with low to moderate dynamic effects. In the lumped parameter approach, three fundamental hydraulic components are involved: the resistor, capacitor and inductor.

- Resistor

- The resistor represents an ideal loss without any inertia or hydraulic

stiffness. Its constitutive equation can be expressed as follows:

This equation states that the mass flow rate is assumed to be proportional to the n-th power of the pressure drop across the component. The exponent can vary between 1 and 0.5, depending on the flow regime (laminar, turbulent, or transition between the two).

- Capacitor

- By contrast to the resistor, the capacitor corresponds to an ideal

hydraulic spring without any losses or inertia. Mathematically, its

behavior is described by the following differential

equation:

According to this model, the temporal change in pressure is proportional to the difference of the incoming and outgoing mass flows, multiplied with the bulk modulus, and divided by the density and volume of the fluid in the respective component.

- Inductor

- The inductor is an ideal inertia without any losses or stiffness. It is

mathematically described by the following equation:

This equation is the hydraulic formulation of Newton's second law of motion. It states that the temporal change in mass flow rate is equal to the pressure difference across the component, multiplied by the cross-sectional flow area, and divided by the length of the component.

Working with Hydraulic Components

The resistors, capacitors and inductors can be used alone or in combination to model actual hydraulic systems. If systems modeled with these components are connected to a circuit model, they form a system of coupled ordinary differential equations which have to be solved numerically. The solving algorithm works in a staggered way: based on the initial pressure distribution, the resistors and inductors calculate flow rates. These flow rates then serve as boundary conditions for the capacitors, which calculate the new pressure distribution in return. After this step, the whole procedure is repeated. Due to the algorithm structure outlined here, any reasonable initial pressures must be assigned to components that are based on capacitor elements, for example simple volumes.