Altair SimSolid 2024.1 Release Notes

Highlights

- Response spectrum analysis

- Collisions of deformed shapes

- Neuber stresses

- Clamping contact condition

- Trapezoidal seam welds

New Features

- Response spectrum analysis

- Response spectrum analysis is a technique used to estimate the maximum response of a structure for a transient event. The time-history of the responses are not available. RSA is a simple and computationally inexpensive method to provide a peak response approximation, compared to conventional transient analysis.

- Collisions of deformed shape

- A new post processing capability is available for both structural and multi-loadcase analysis that finds possible collisions on all deformed parts in the assembly. The collisions can be found within a user-specified gap tolerance. The tool displays and lists all the possible collisions between all the deformed parts in the assembly.

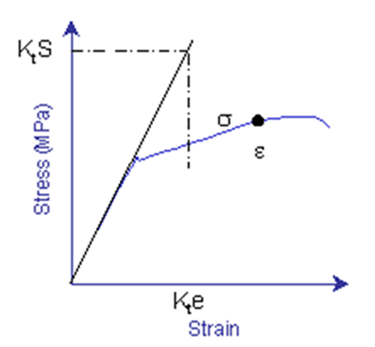

- Neuber stress

- Neuber stresses/strains can be obtained by running linear structural analysis and Neuber correction can be used to evaluate approximate local plasticity. This method is computationally inexpensive as Neuber stresses/strains are output without running a full-fledged nonlinear analysis. To successfully output Neuber results, material stress-strain curves are required to be input.

- Clamping contact condition

- A new contact condition called Clamping is now supported for structural analysis. The clamping contact condition allows parts to align in normal direction only, while allowing sliding between parts. Loads are applied internally to clamp the parts together. Graphics icon for clamping is a purple point cloud. The clamping condition is available only as a custom contact condition for structural analysis.

- Trapezoidal seam welds

- The implicit seam welds created can now have a trapezoidal shape in addition to the existing prismatic shapes. This capability is available for both weld by lines/edges and weld from solids.

Enhancements

- Multi-loadcases

-

- Several new boundary conditions are now supported under multi-loadcases including gravity, hydrostatic pressure, translational and rotational inertia, thermal loads, distributed mass and volumetric expansion/shrinkage.

- Result graph is supported.

- Export of deformed shape is supported.

- Fatigue safety factor

- A new safety factor output is now available for fatigue analysis. Safety factor is available for fatigue via back-calculation to calculate scaling factor for a particular target life. It can be activated using fatigue solution settings.

- Imported loads

- Imported loads are now supported. Several loads can be imported from a CSV file including pressure for structural analysis and temperature, flux, convection for steady-state thermal analysis.

- Composites (Beta)

-

- Orthotropic materials can be applied to plies within the laminates.

- Orthotropic material orientation can also be applied but it is limited to flat shapes.

- Separating/closing and Separating contact

- The contact conditions are now enhanced and made robust. The closing contact will work with gaps within the small-sliding zone. Any penetrations are automatically resolved when separating/closing contact is used.

- Others

-

- Part info is available for several parts in the assembly.

- ECAD files reader has been updated.

- Spot weld visualization has been improved where 2T, 3T, and 4T spot welds can be visualized in different colors. The 2T spot welds are highlighted in red, 3T in cyan, and 4T in pink.

- The adaptation for sheets has been improved which should resolve several numerical instabilities that yield error ID 18.

- Data imported from CSV files can now read more decimal places.

Known Issues

The following known issues will be addressed in a future release as we continuously

improve performance of the software.

- Issues with linear guide joint under virtual connectors.

Resolved Issues

- Laminate creation and editing have been re-factored to improve the workflow.

- Issues related to updating the units appropriately.

- Issues related to result plots have been resolved.

- Issues with importing fatigue material properties from a CSV file to material database.

- Issues related to re-using adaptation from previous steps leading to performance issues.

- Remote loads are updated appropriately when edited.

- Improved display issues with selection of parts.

- Improved creation of connections.

- Improved creation of seam welds.

- Status bar is updated appropriately when solution is being prepared before solving.

- Improved approximation of spots, when thermal loads are applied on spots.

- Result quantity labels are fixed when running dynamic analysis with displacement base excitation.

- Fixed issues and inconsistencies related to creation of virtual connectors.

- Issues related to dynamic reactions along bushing coordinate system.

- Improved error messages.

- Inconsistencies with plotting and saving results.

- Fixed issues related to boundary condition visualization.

- Boundary conditions can be applied to the face where distribution mass is applied.

- Issues related to handling boundary conditions appropriately in local studies.

- Issues related to complex eigenvalue analysis linked to geometric nonlinear analysis.

- Issues related to selection of material database.

- Issues related to assembly info with laminates.

- Issues related to bookmarks.

- Issues related to bolt forces.

- Several crashes have been fixed.

- Several instabilities have been resolved with improved adaptation.