Pouring Cup Test

Use the basin (cup) icon to run an optional pouring cup test to evaluate a material that you want to assign to your model for a foaming simulation.

Location: Foaming ribbon,

Pouring Basin satellite icon on the Foam

Part icon.

The pouring cup test shows you how parameters such as temperature and fill percentage can determine the foaming behavior of a material relative to a particular mold shape. The simulated expansion of the foam can help you determine the optimal conditions and material amounts to use in the physical manufacturing of the foam part.

The pouring cup test is conducted separately from the foam part setup and simulation. Run a pouring cup test before loading your foam part model, otherwise you will be prompted to close your model.-

Hover over the Foam Part icon and click the

Pouring Basin satellite icon.

The default basin appears prefilled at 20%.

-

Use the microdialog options to define the basin and material, and to run the

test.

Microdialog option Description

Select a shape for the pouring basin, then expand the dialog and enter the dimensions for the basin: - For the cylinder, enter a radius and height.

- For the cone, enter a bottom radius, top radius and height.

- For the cube, enter a length, width and height.

Specifiy the amount of material in the basin at the start of the test either by mass (in units) or volume (as a percentage of the basin capacity). The default prefill is 20% of the basin's capacity.

Click the View Materials  button to open the Materials

dialog and review the material properties of your selected

material. You can also edit, import, export and assign

materials from this dialog.

button to open the Materials

dialog and review the material properties of your selected

material. You can also edit, import, export and assign

materials from this dialog.

Select a material for the pouring cup test. You can also assign a material from the Materials dialog.

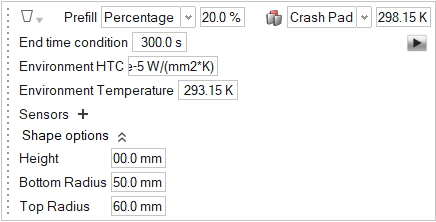

Enter the initial temperature for the selected foaming material. End time condition Enter the desired duration of the test in seconds. The default value of 300 seconds will usually be sufficient. Environmental HTC Enter the environmental heat transfer coefficient for the material. Environmental Temperature Enter the ambient temperature for the simulation. Sensors

Click the  to place one or more virtual

sensors in the pouring cup, if desired. The sensors will

show data from their location during the simulation.

to place one or more virtual

sensors in the pouring cup, if desired. The sensors will

show data from their location during the simulation.

Shape options

Click the chevrons to reveal fields that control the dimensions of the pouring cup.

Click the Run  button to run the pouring cup

test.

button to run the pouring cup

test. - Select the completed run in the Run Status window.

-

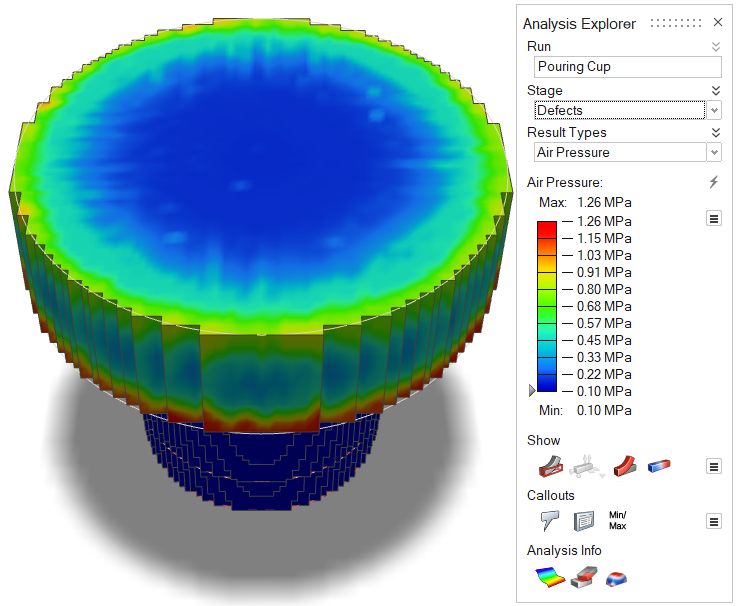

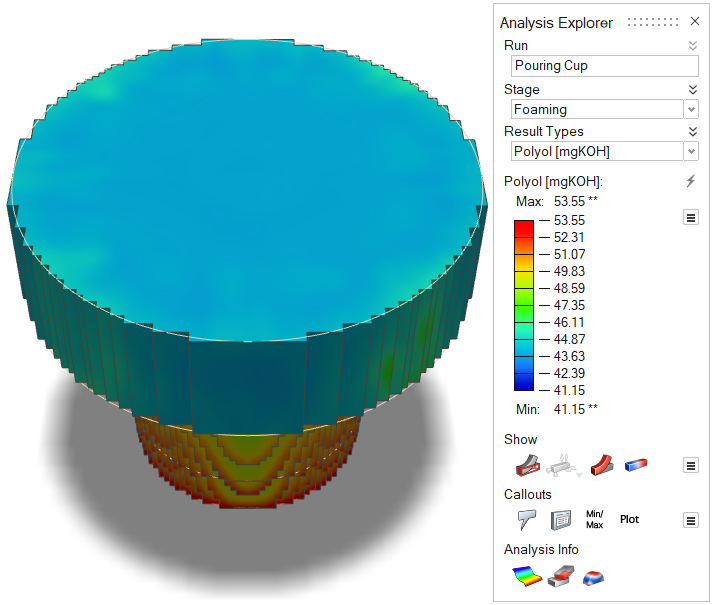

Select a Stage and Result Type in the Analysis Explorer and review the

results.

The following examples show results for the Crash Pad material in a cone basin with default settings.

Figure 1. Air pressure results for the defects stage

Figure 2. Polyol [mgKOH] results for the foaming stage  Note: To view data from sensors, select the Callouts

Note: To view data from sensors, select the Callouts button in the Analysis

Explorer.

button in the Analysis

Explorer.