Result Types

A set of result types is available for each of the four analysis stages: injection, foaming, curing and defects.

Injection Results

Review material behavior through the injection stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Velocity, Mold Temperature, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

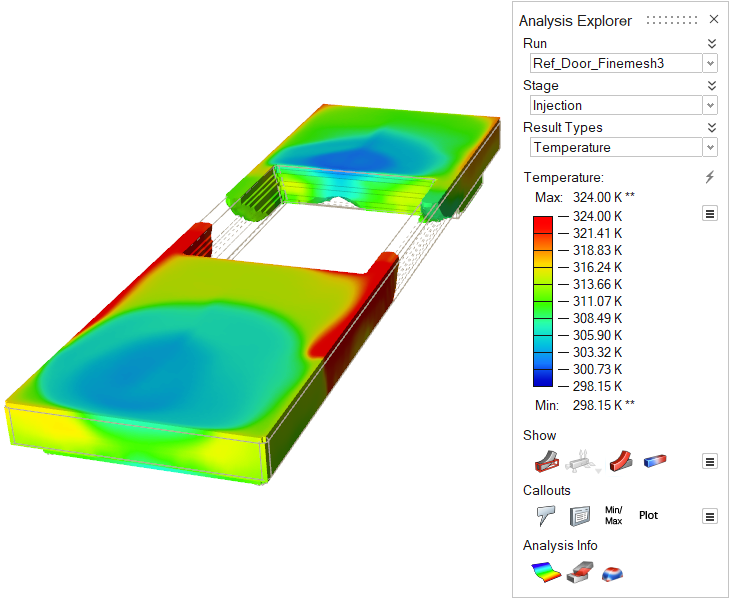

| Temperature | Review the temperature evolution of the material entering the

part cavity. Check regions for excessive heating or cooling.

Determine the appropriate fill speed for uniform temperature

distribution. |

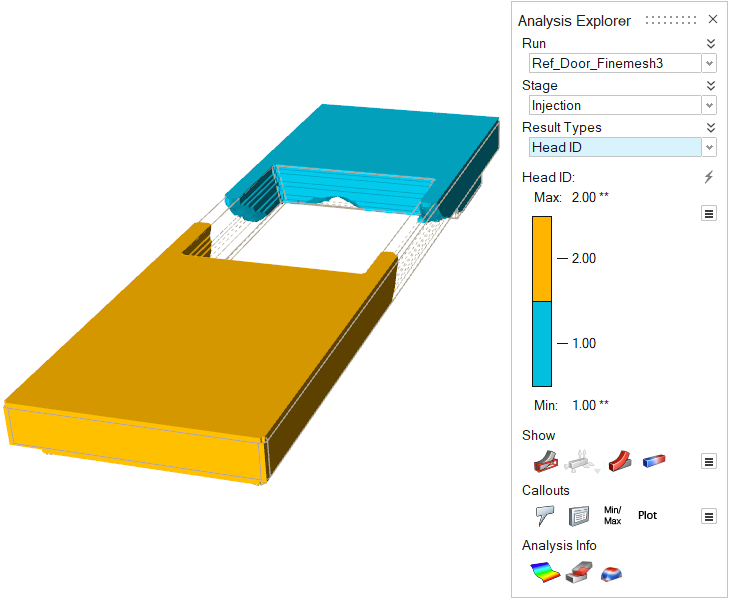

| Head ID | Review injection results for material coming from a

particular nozzle. |

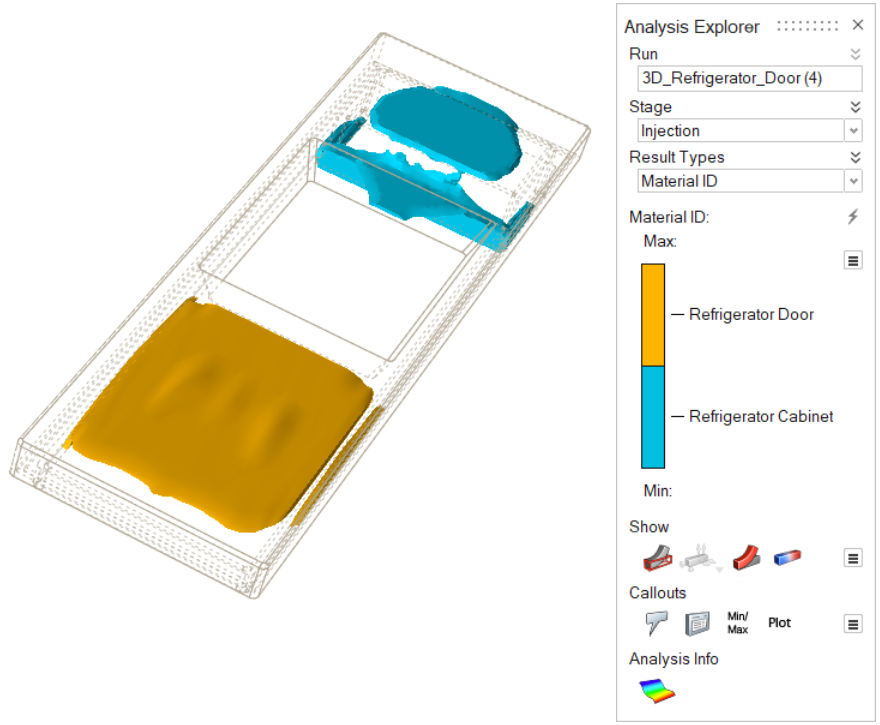

| Material ID | Review results for a particular material. |

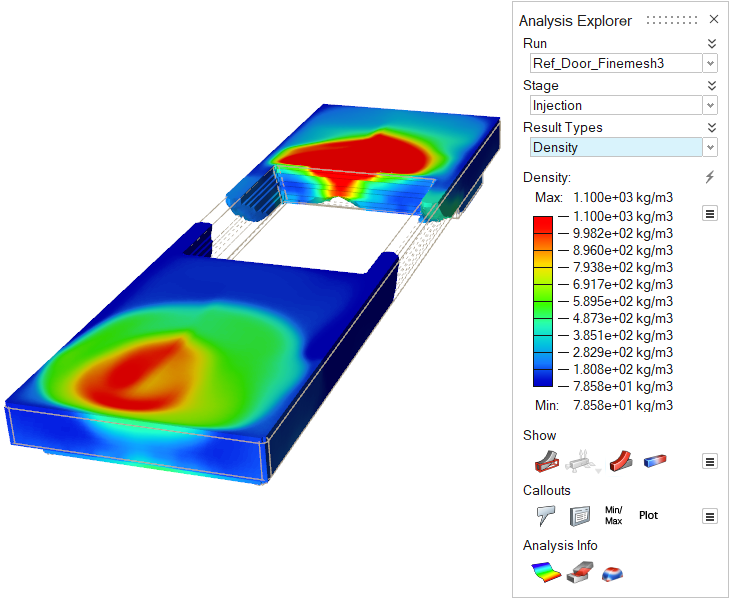

| Density | Consider material density through the progression of the

injection stage. |

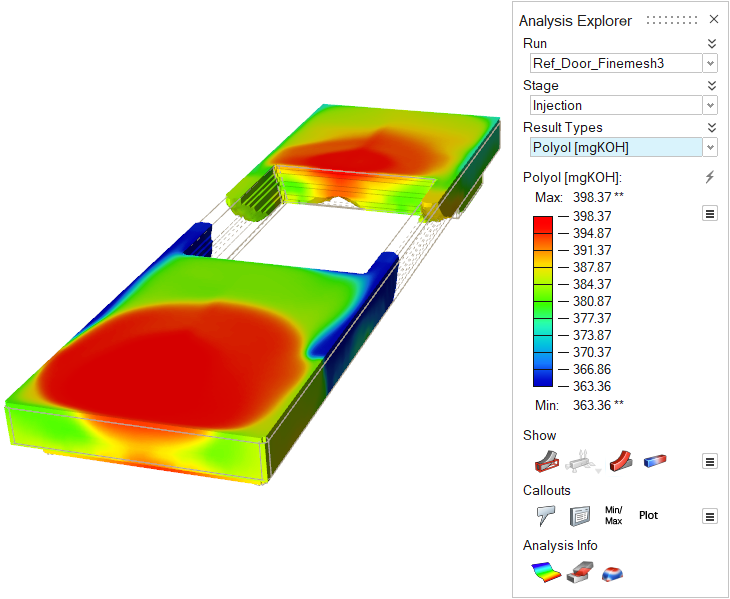

| Polyol [mg KOH] | Review the levels of polyol that remain in the material. The

initial level will be equal to the mixing ratio and will

decrease during the polyurethane reaction. |

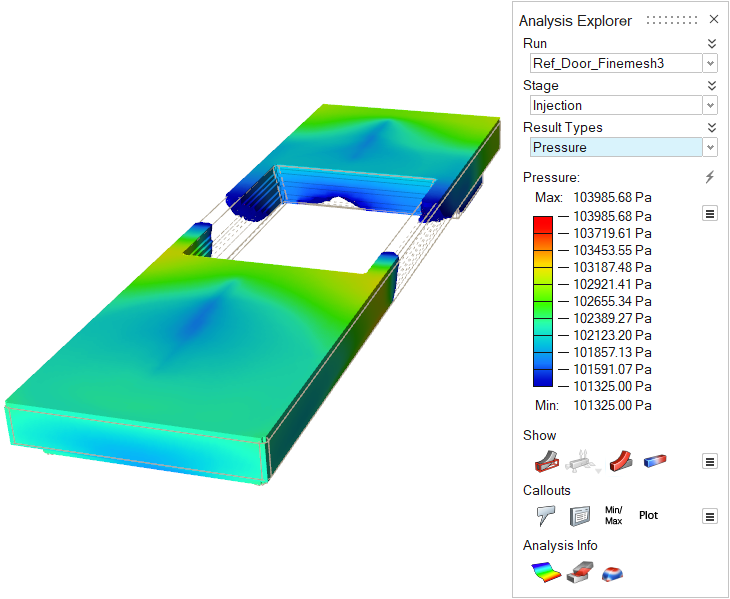

| Pressure | Review the impact of pressure on the material during the

injection stage. |

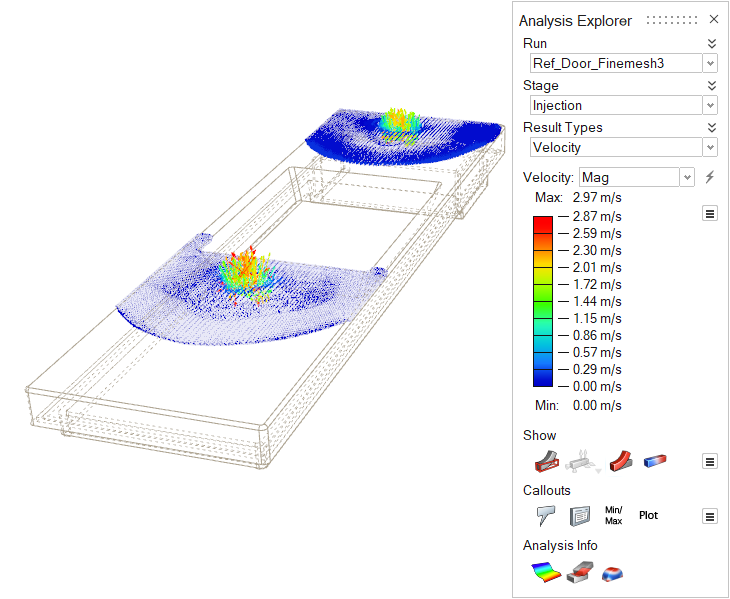

| Velocity | Review the velocity of the polyurethane material to detect

turbulences that can cause defects. Velocity is affected by

pressure, mold cavity shape, the polyurethane reaction itself,

and other factors.  Note: To enable vectors, click the  icon under the Show heading in

the Analysis Explorer window, and enable Vector

Plot. icon under the Show heading in

the Analysis Explorer window, and enable Vector

Plot. |

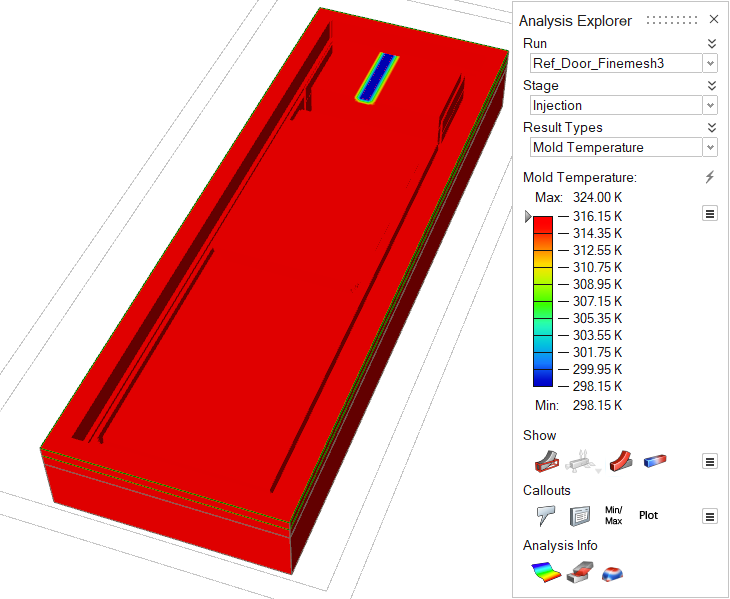

| Mold Temperature | Review the temperature variance in the mold throughout the

injection stage. |

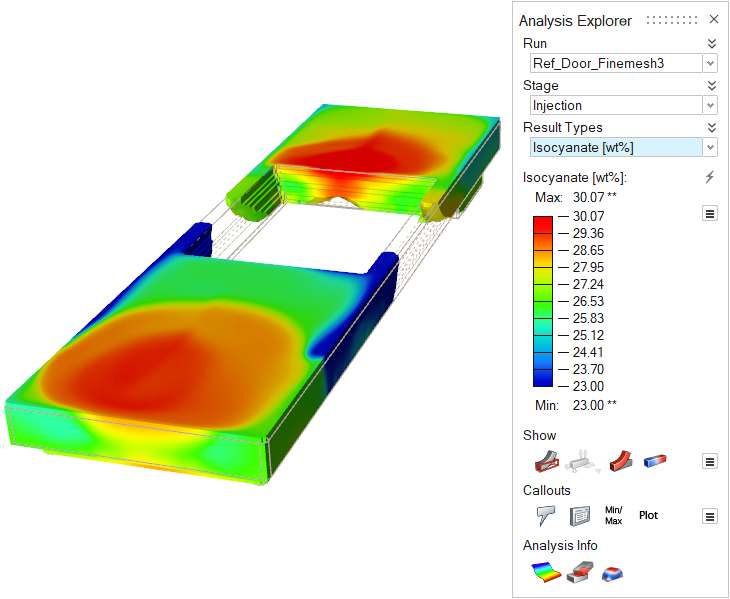

| Isocyanate [wt%] | Review the levels of isocyanate that remain in the

polyurethane material. The initial value will be equal to the

mixing ratio, and will decrease during the polyurethane

reaction.  |

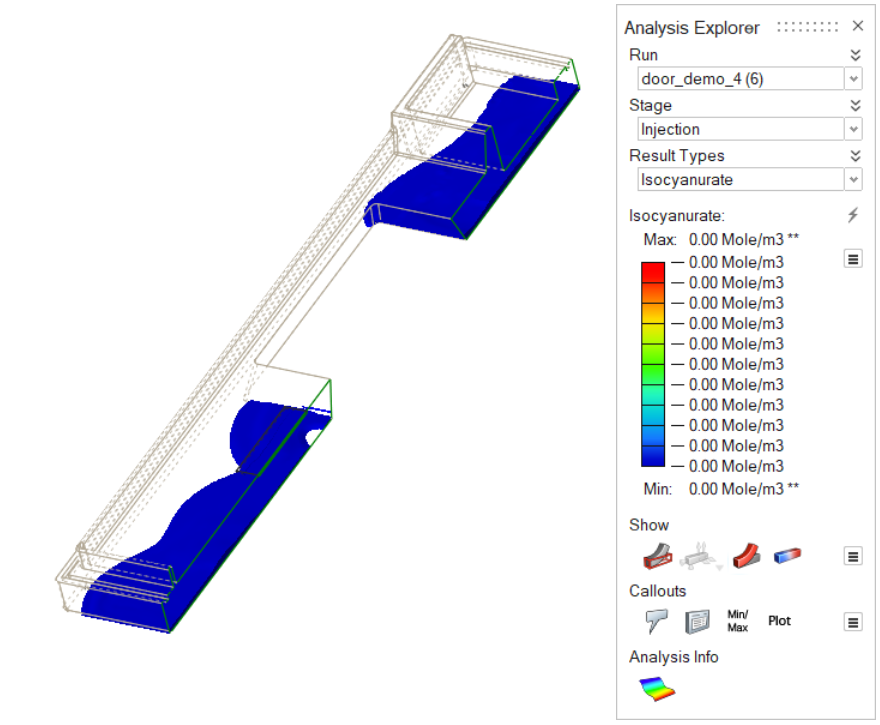

| Isocyanurate | Review the level of isocyanurate that is forming in the

polyurethane model. Polyisocyanurate requires a relatively high

temperature and an index greater than 180. (Find the material's

index in the Mixing Ratio tab in the Materials

window.)  Note: To get

an isocyanurate result, you must:

|

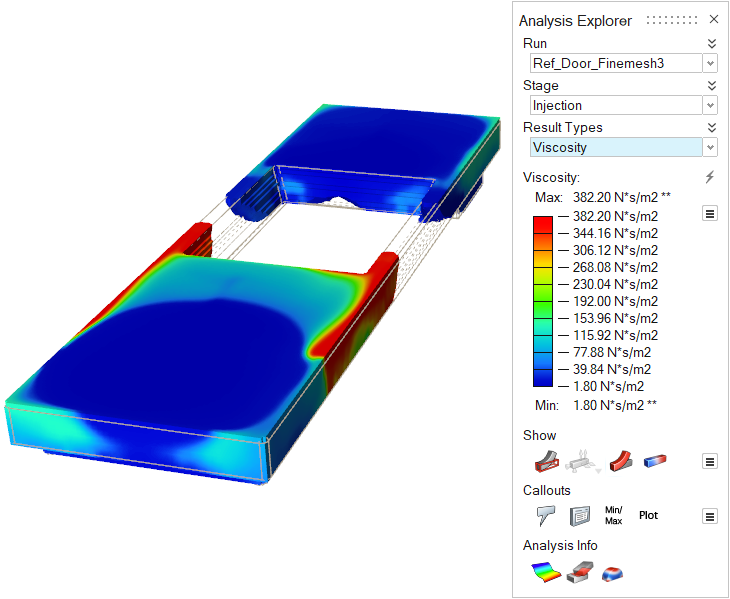

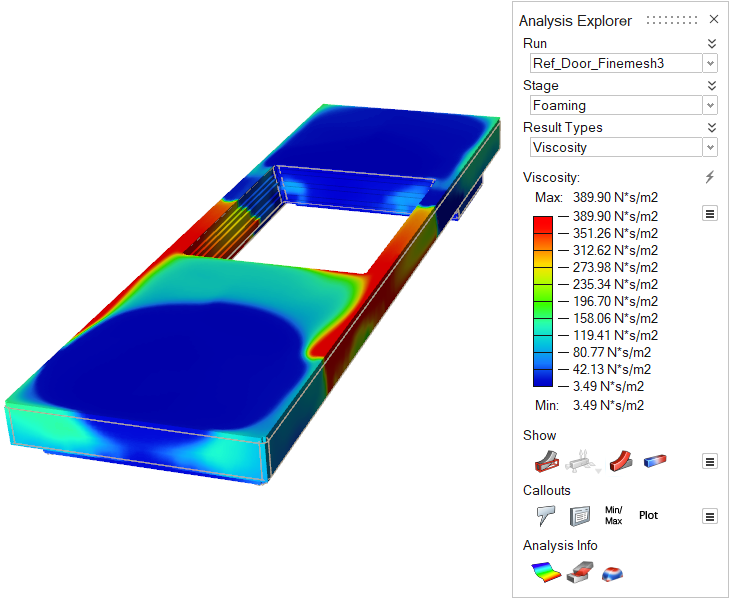

| Viscosity | Review the dynamic viscosity of the polyurethane material.

Viscosity will increase over the course of the process. |

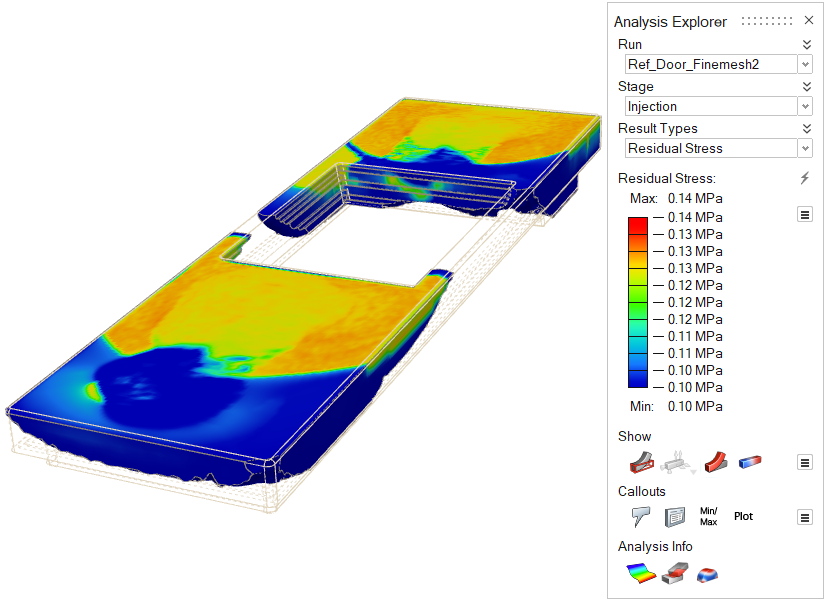

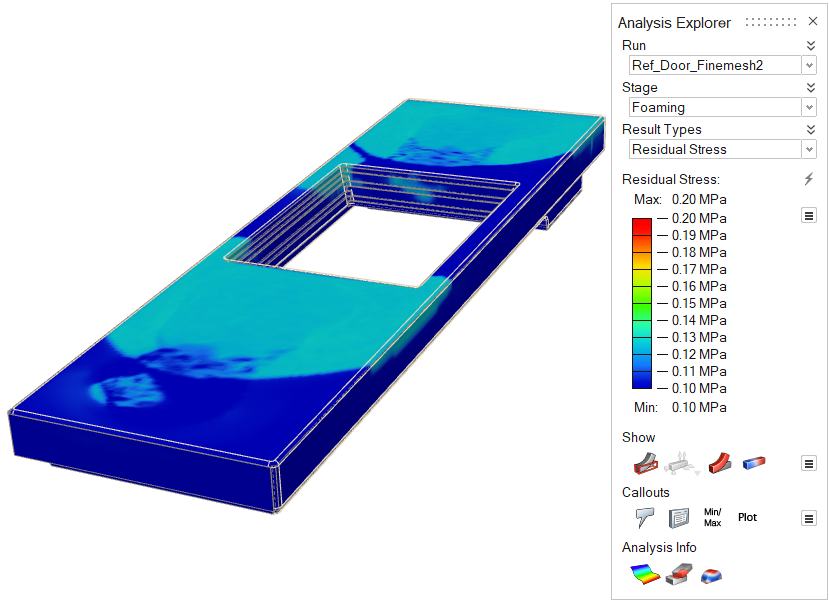

| Residual Stress | Residual stress is pressure from gas generated during the

foaming reaction without density change in the material.

Residual stress values will be low during the injection stage.

Temperature, foam density, and concentration of blowing agents

affect Residual Stress. This result is only available when rigid

polyurethane and a mold are in use.  |

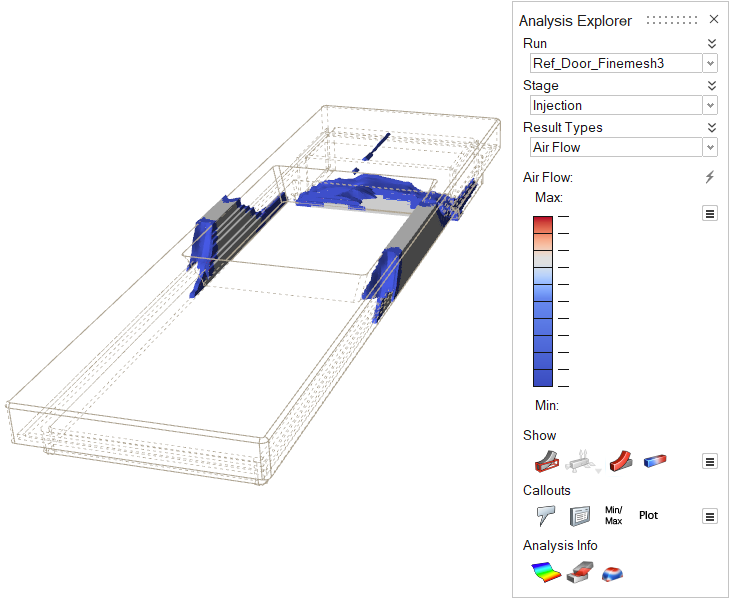

| Air Flow | View the behavior of air inside the mold during the injection

process. As material enters the cavity, air inside the mold

pushes out through vents, parting lines, and filling systems.

|

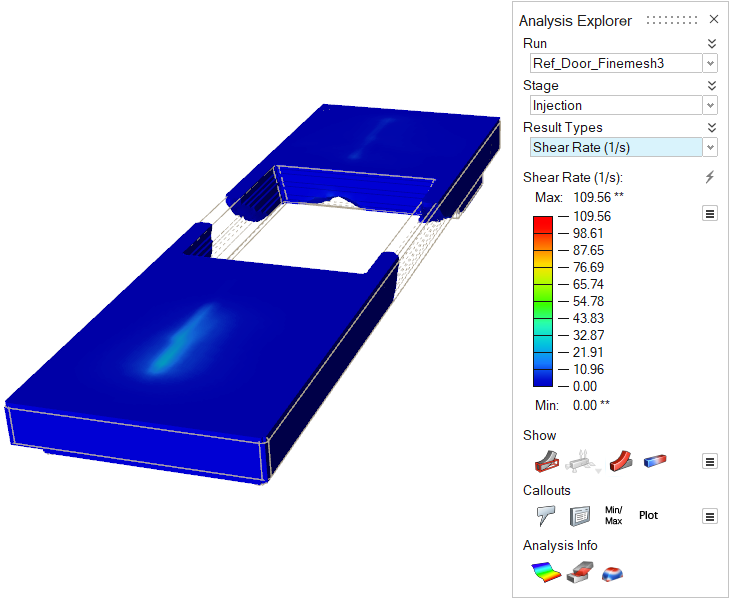

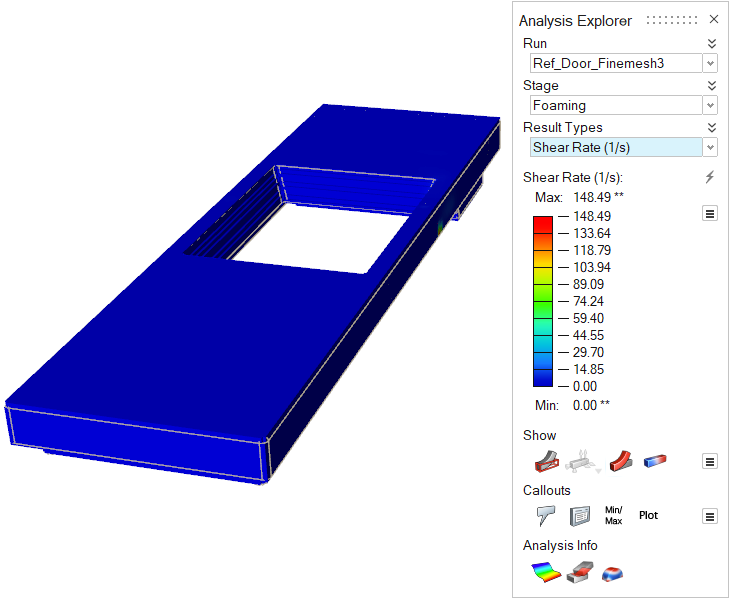

| Shear Rate | Review the rate at which a progressive shearing deformation

is applied to the material during the injection process. Because

the velocity difference is large and the shear rate increases on

the mold surface, you can use this result as an indicator of

surface defects along with the shear stress result. A high shear

rate generally indicates a lot of deformation.  |

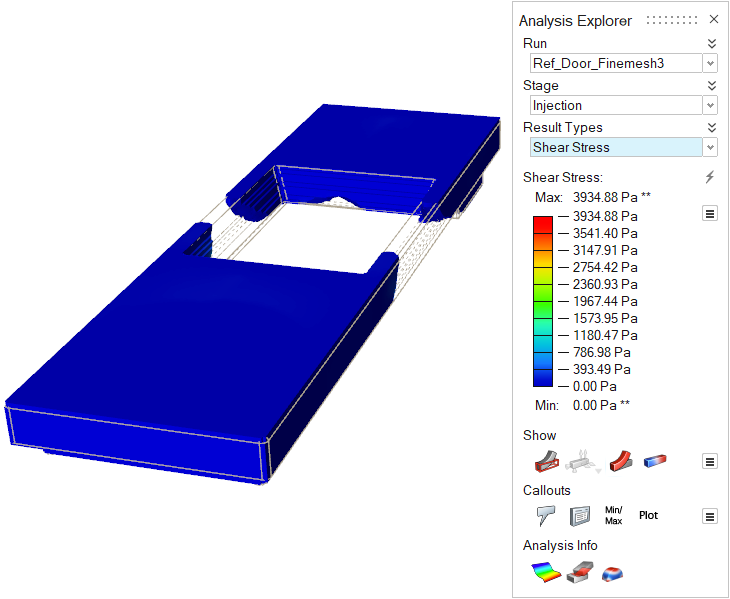

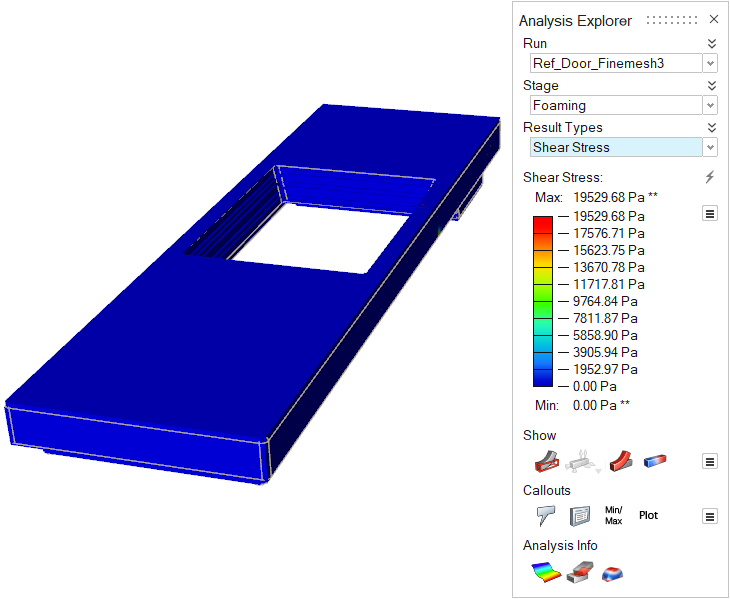

| Shear Stress | Shear stress is one of the forces that can cause deformation

of the material by slippage along a plane. You can use this

result along with the viscosity and shear rate results to

predict surface defects. You can also use this result as an

indicator for resistance to filling. |

Foaming Results

Review material behavior through the foaming stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Velocity, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

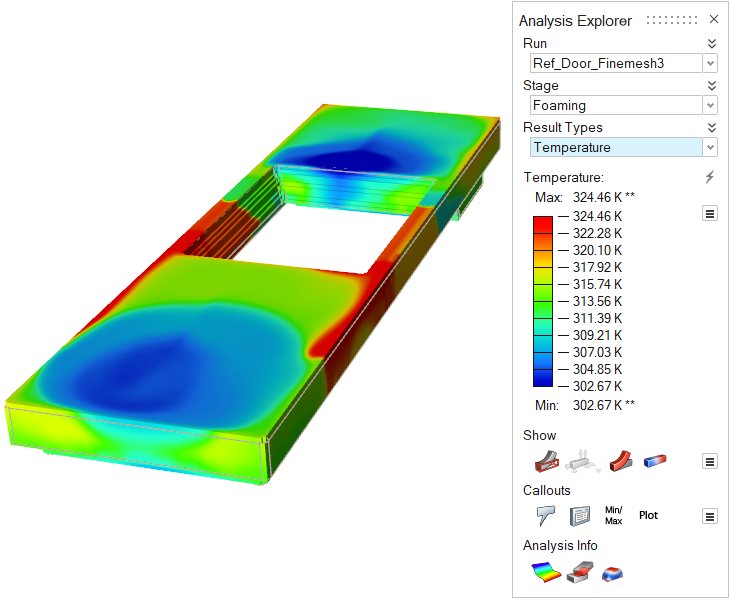

| Temperature | Review the temperature evolution of the material during the

foaming stage. |

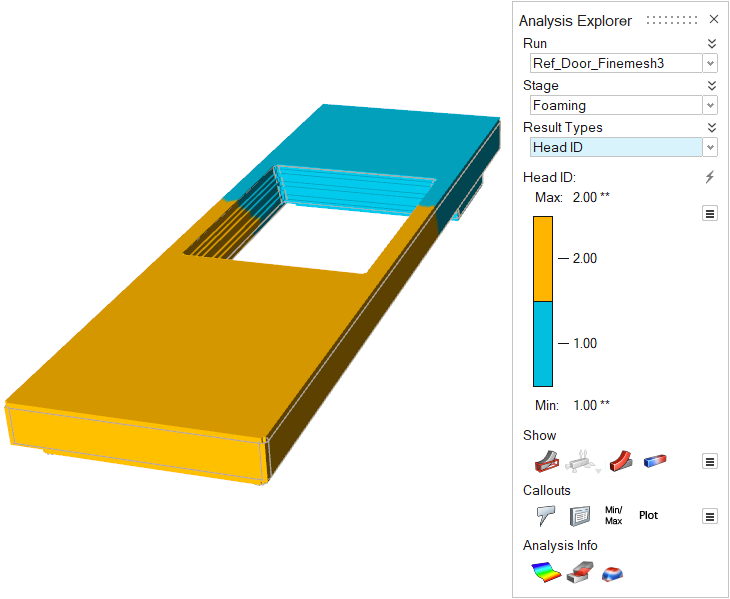

| Head ID | Review the foaming results for material coming from a

particular nozzle. |

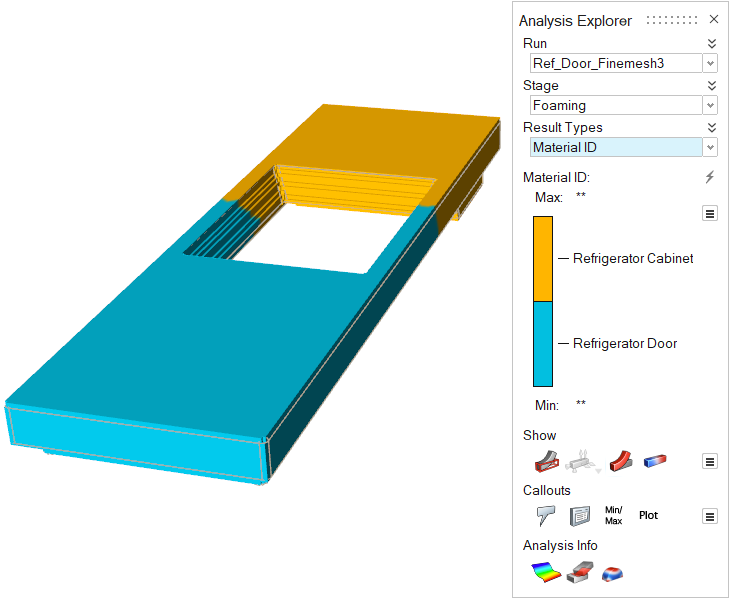

| Material ID | Review results for a particular material. |

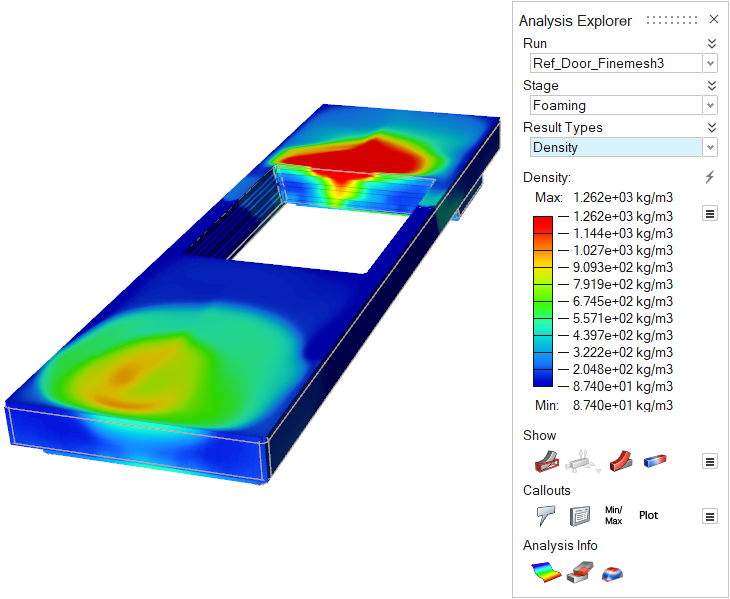

| Density | Consider material density through the progression of the

foaming stage. |

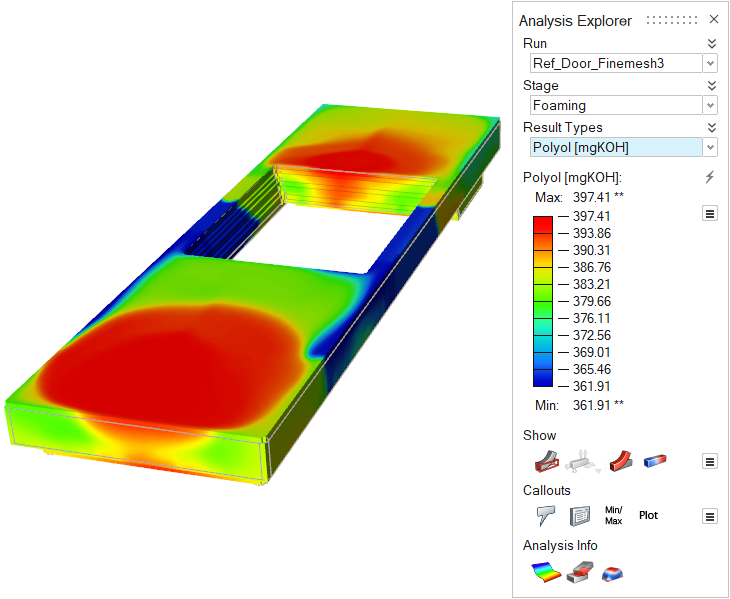

| Polyol [mg KOH] | Review the levels of polyol that remain in the material. The

initial level will be equal to the mixing ratio and will

decrease during the polyurethane reaction. |

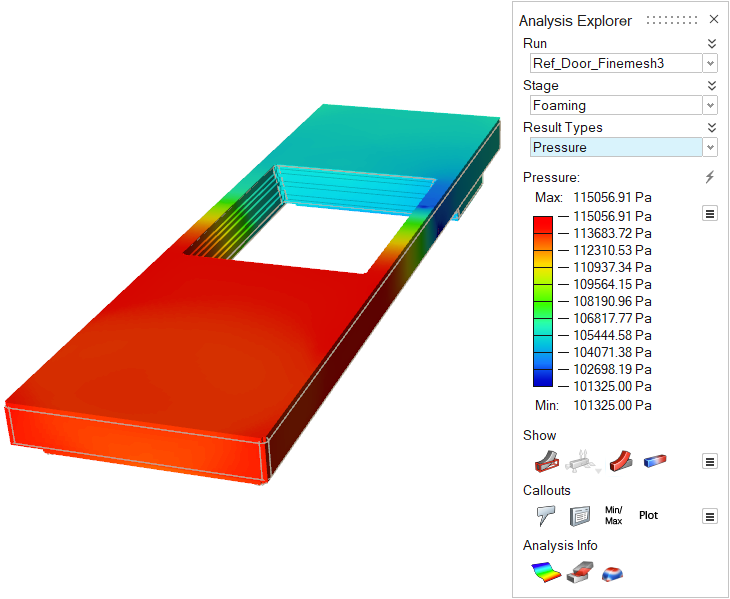

| Pressure | Review the impact of pressure on the material during the foaming stage.  |

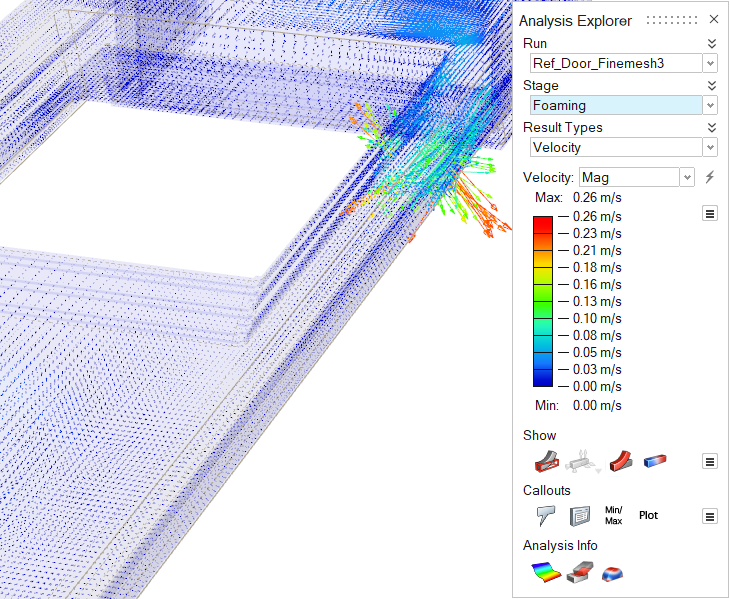

| Velocity | Review the velocity of the polyurethane material to detect turbulences that can cause defects. Velocity is affected by pressure, mold cavity shape, the polyurethane reaction itself, and other factors.  Note: To

enable vectors, click the  icon under the Show heading in

the Analysis Explorer window, and enable Vector

Plot. icon under the Show heading in

the Analysis Explorer window, and enable Vector

Plot. |

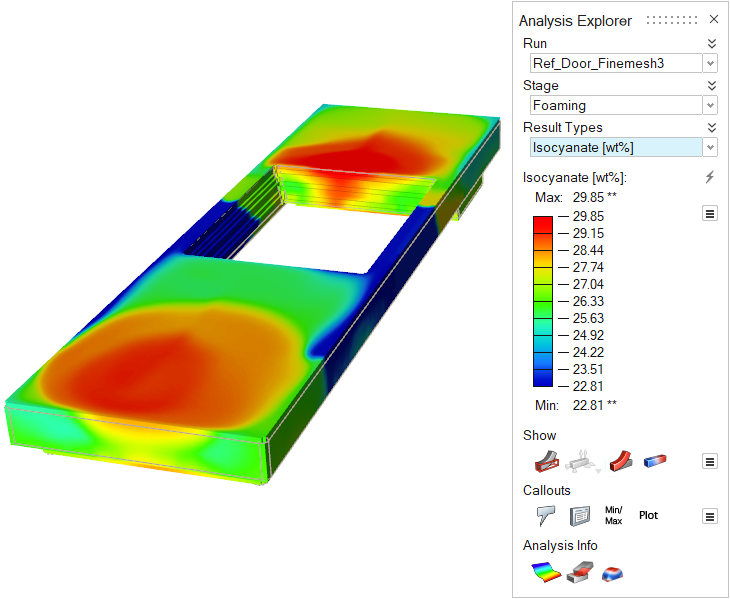

| Isocyanate [wt%] | Review the levels of isocyanate that remain in the

polyurethane material. The initial value will be equal to the

mixing ration, and will decrease during the polyurethane

reaction.  |

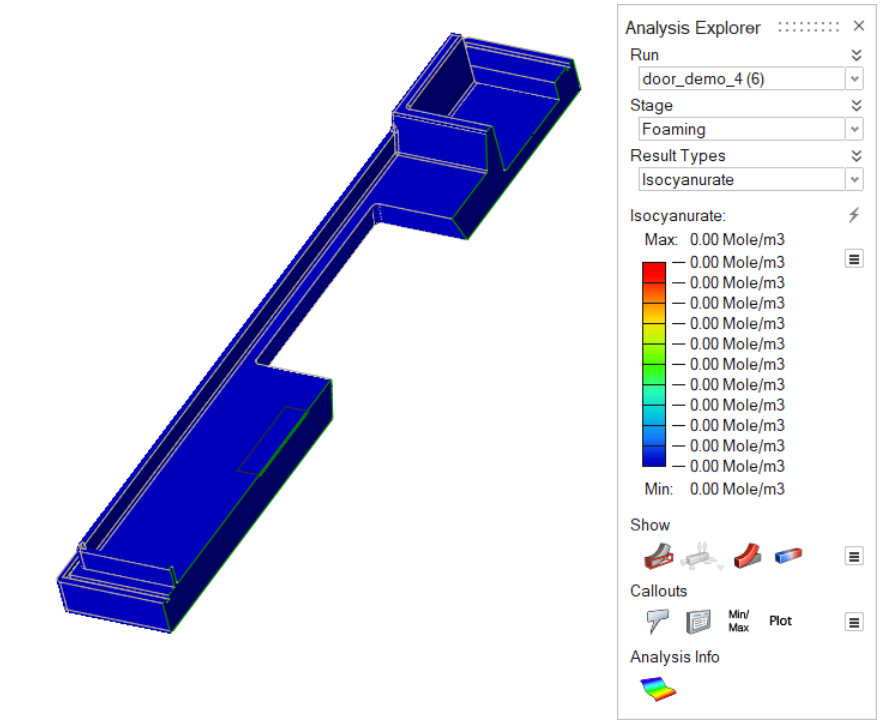

| Isocyanurate | Review the level of isocyanurate that is produced in the

polyurethane model. |

| Viscosity | Review the dynamic viscosity of the polyurethane material.

Viscosity will increase over the course of the process. |

| Residual Stress | Residual stress is pressure from gas generated during the

foaming reaction without density change in the material.

Residual stress gradually decreases after reaching its maximum

value. Temperature, foam density, and concentration of blowing

agents affect Residual Stress. This result is only available

when rigid polyurethane and a mold are in use.  |

| Air Flow | View the behavior of air inside the mold during the foaming

process. As material fills the cavity, air inside the mold

pushes out through vents, parting lines, and filling systems.

|

| Shear Rate | Review the rate at which a progressive shearing deformation

is applied to the material during the foaming process. Because

the velocity difference is large and the shear rate increases on

the mold surface, you can use this result as an indicator of

surface defects along with the shear stress result. A high shear

rate generally indicates a lot of deformation.  |

| Shear Stress | Shear stress is one of the forces that can cause deformation

of the material by slippage along a plane. You can use this

result along with the viscosity and shear rate results to

predict surface defects.  |

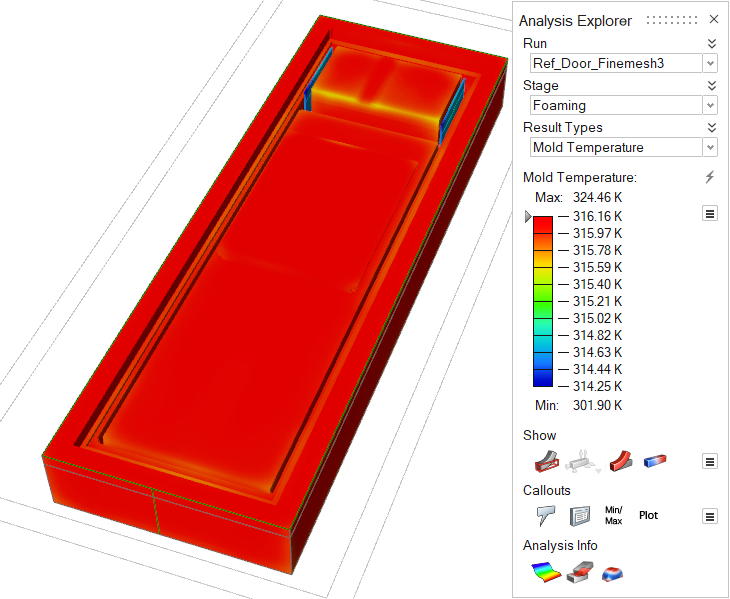

| Mold Temperature | Review the temperature variance in the mold throughout the

foaming stage.  |

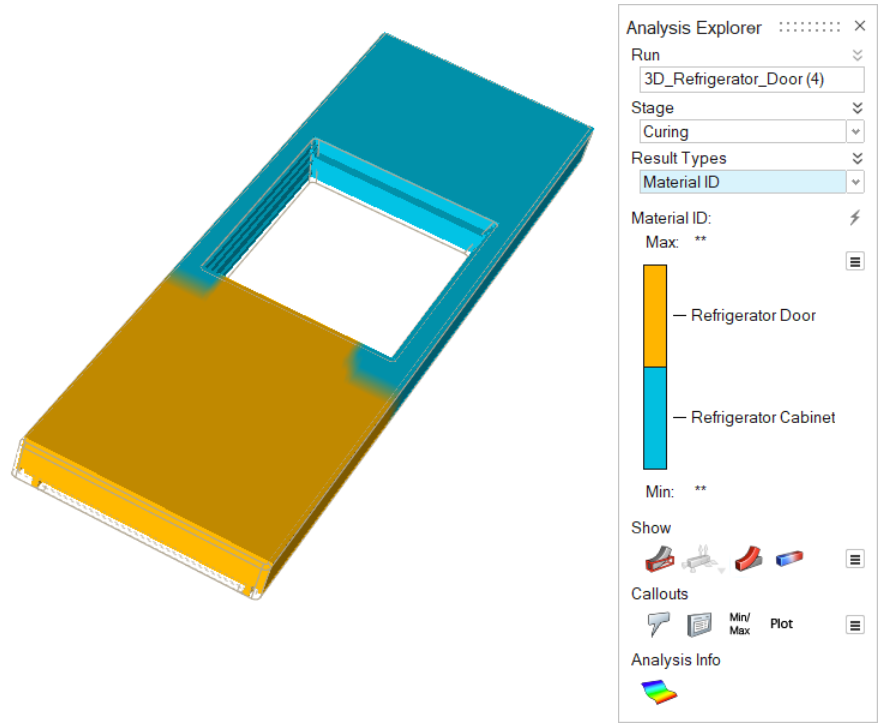

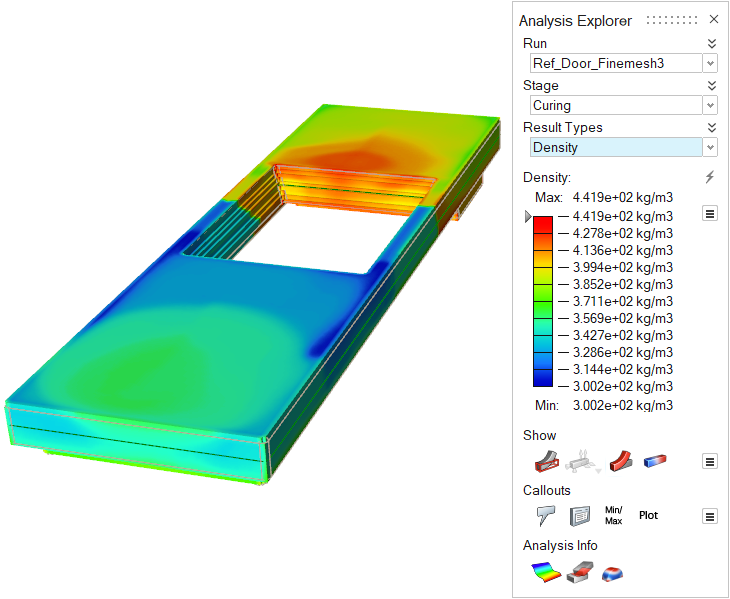

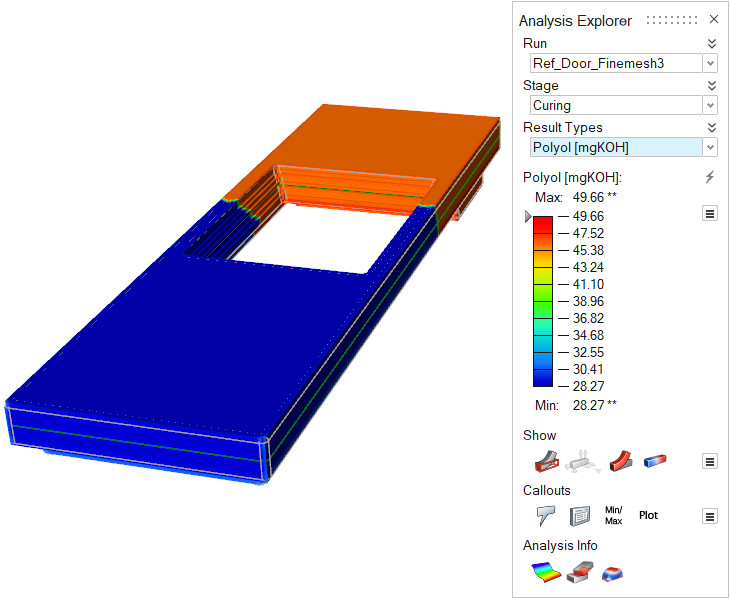

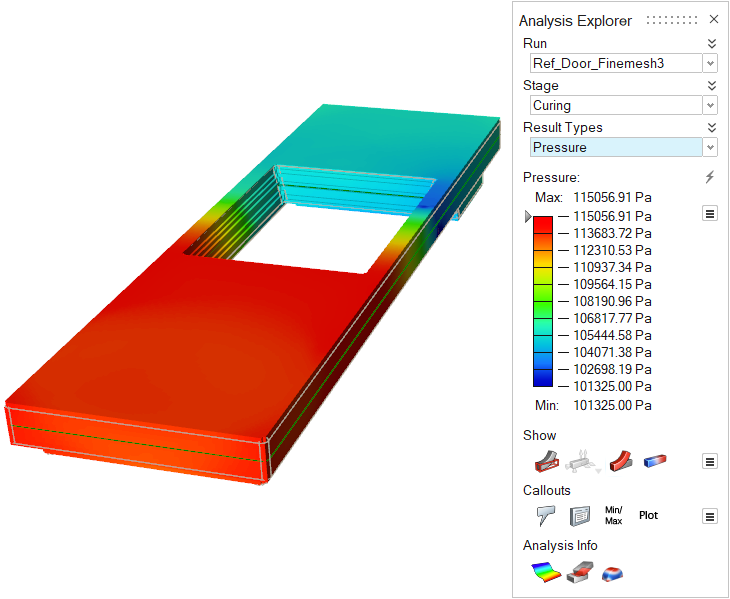

Curing Results

Review material behavior through the curing stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

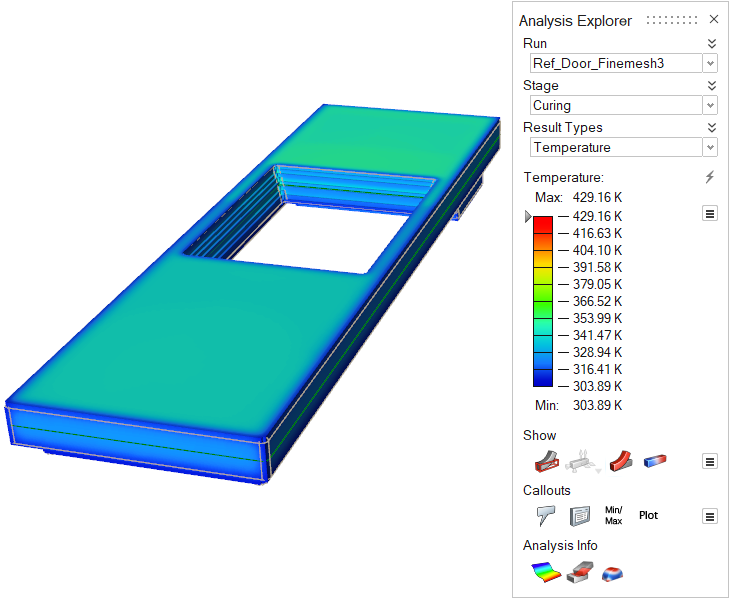

| Temperature | Review the temperature evolution of the material during the

curing stage. Check regions for excessive heating or

cooling. |

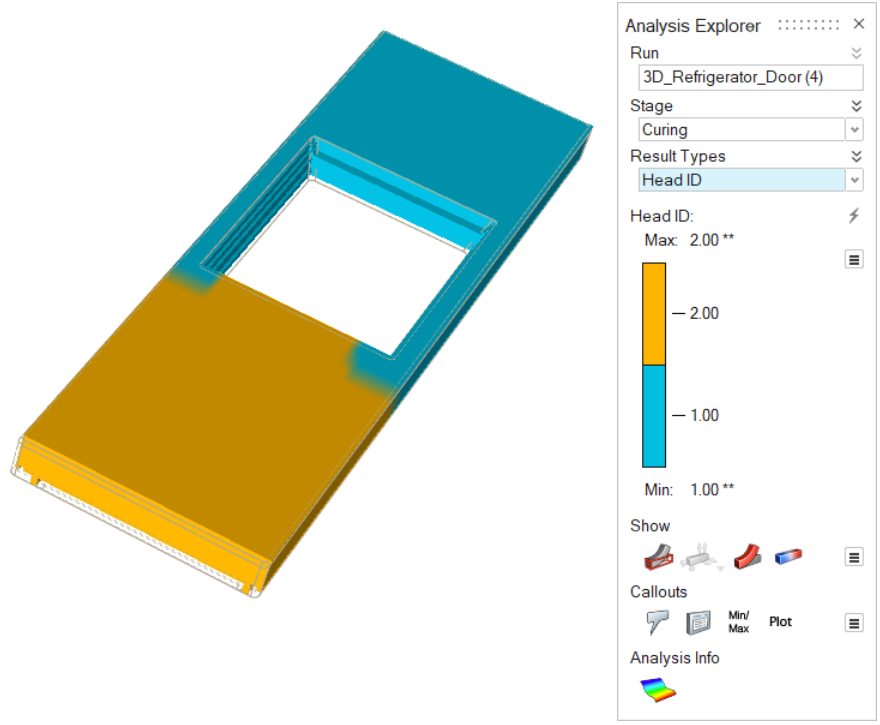

| Head ID | Review curing results for the material coming from a

particular nozzle. |

| Material ID | Review the curing results for a particular material. |

| Density | Consider material density during the curing stage. |

| Polyol [mgKOH] | Review the levels of polyol that remain in the material. The

initial level will be equal to the mixing ratio and will

decrease during the polyurethane reaction. |

| Pressure | Review the impact of pressure on the material during the

curing stage. |

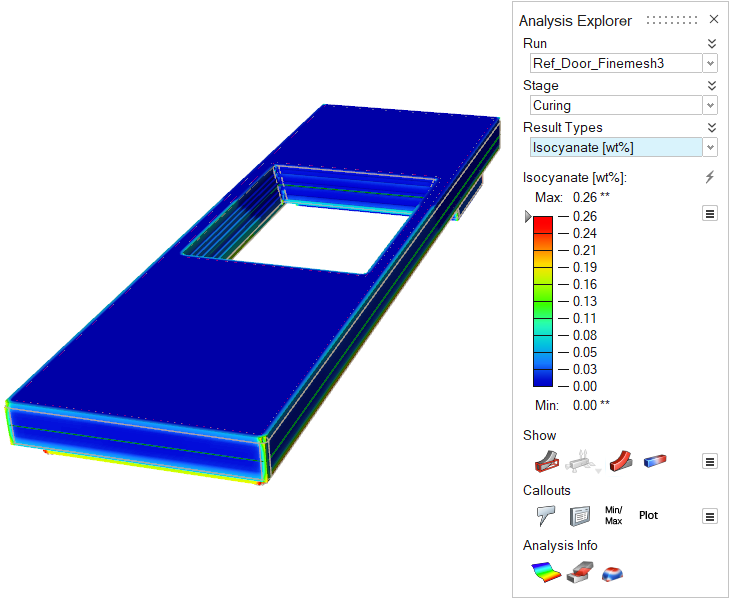

| Isocyanate [wt%] | Review the levels of isocyanate that remain in the

polyurethane material. The initial value will be equal to the

mixing ration, and will decrease during the polyurethane

reaction.  |

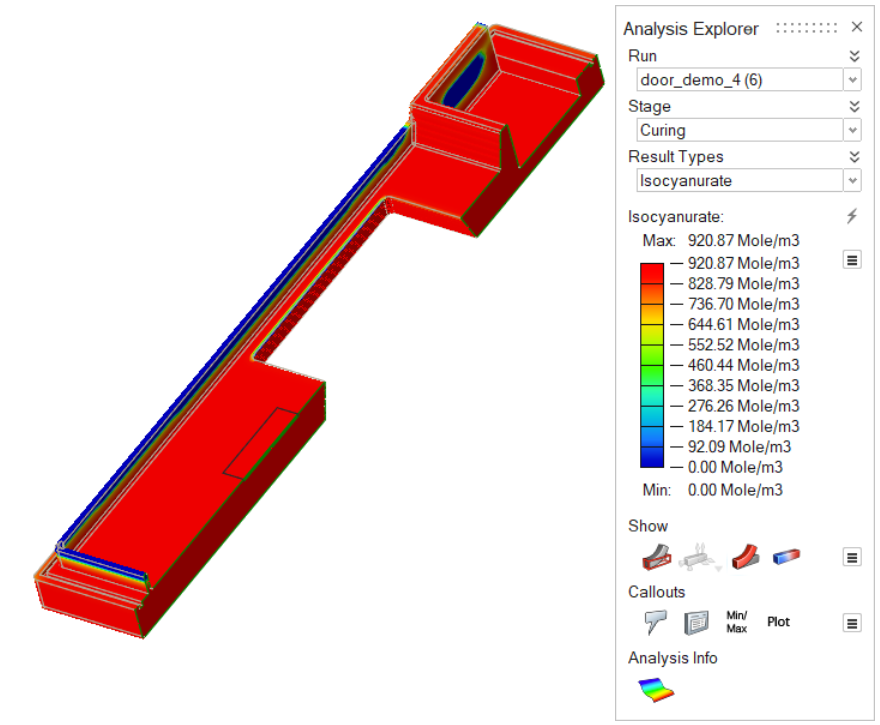

| Isocyanurate | Review the level of isocyanurate that is produced in the

polyurethane model. |

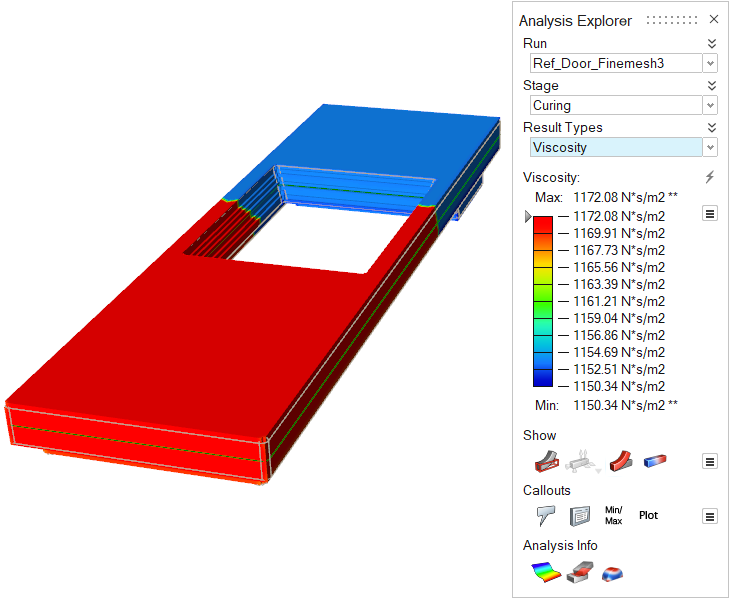

| Viscosity | Review the dynamic viscosity of the polyurethane material.

|

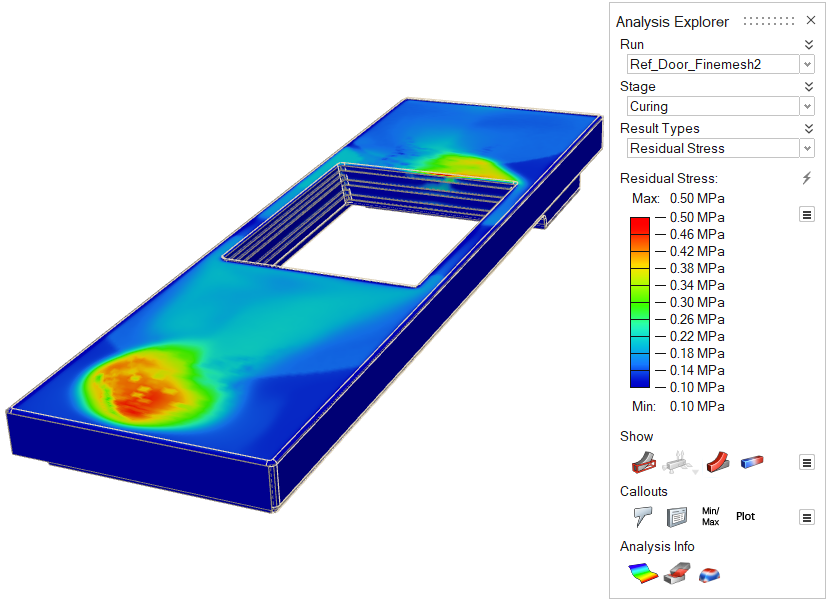

| Residual Stress | Residual stress is pressure from gas generated during the

foaming reaction without density change in the material.

Residual stress gradually decreases after reaching its maximum

value. Temperature, foam density, and concentration of blowing

agents affect Residual Stress. This result is only available

when rigid polyurethane and a mold are in use.  |

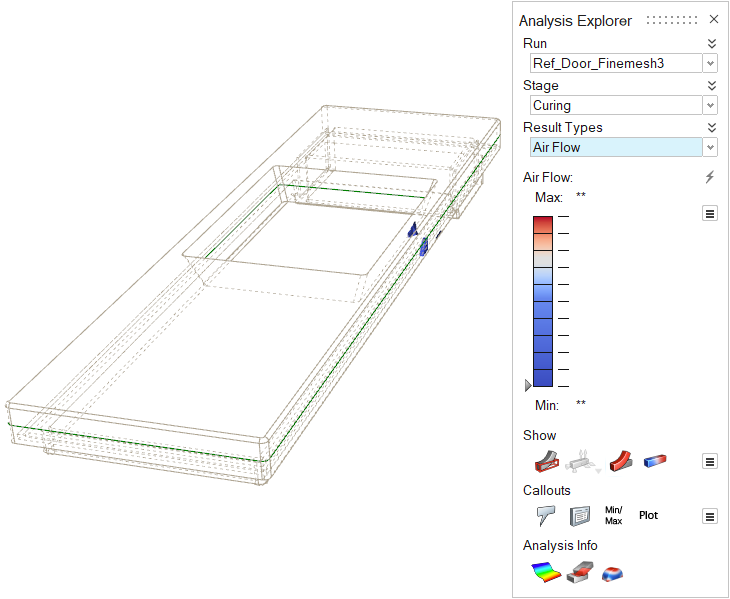

| Air Flow | View the behavior of air inside the mold during the curing

process. As material changes shape inside the cavity, air can

enter the mold through vents, parting lines, and filling

systems. |

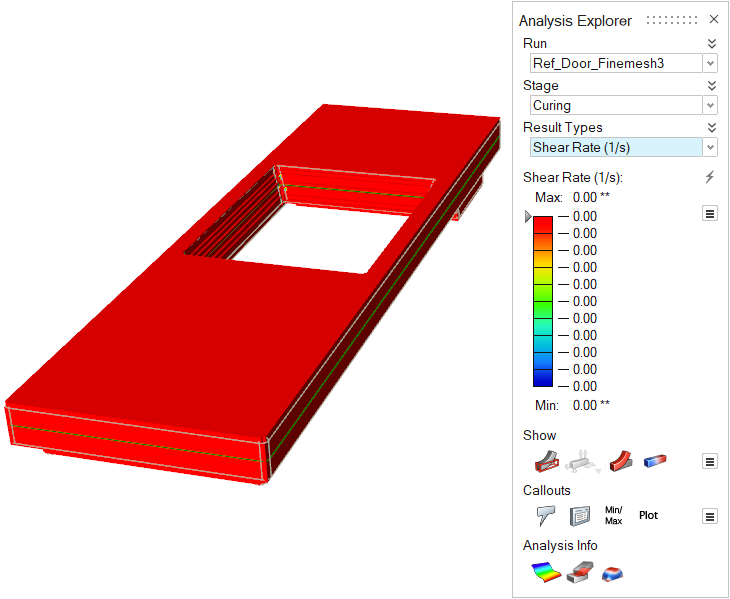

| Shear Rate | Review the rate at which a progressive shearing deformation

is applied to the material during the curing process. Because

the velocity difference is large and the shear rate increases on

the mold surface, you can use this result as an indicator of

surface defects along with the shear stress result. |

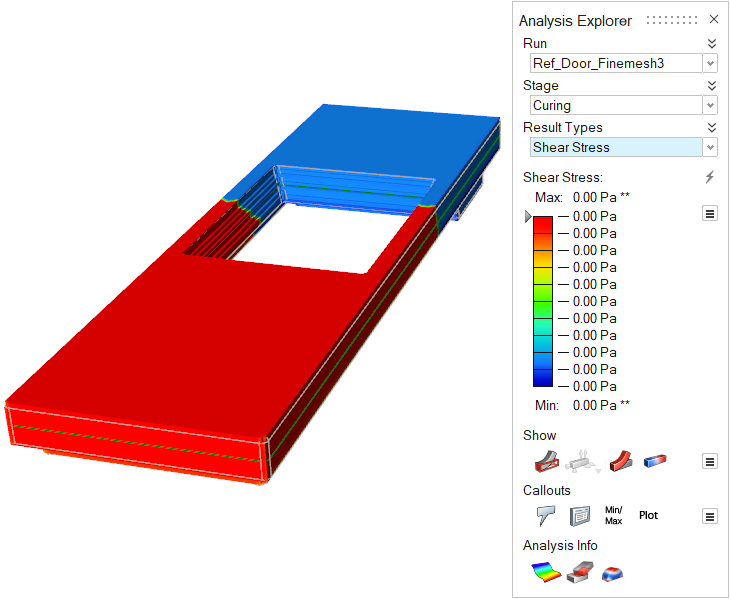

| Shear Stress | Shear stress is one of the forces that can cause deformation

of the material by slippage along a plane. You can use this

result along with the viscosity and shear rate results to

predict surface defects.  |

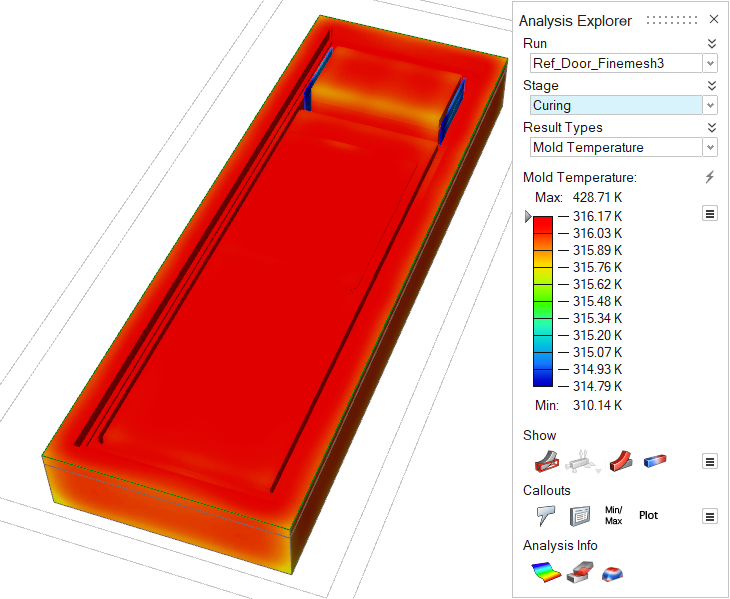

| Mold Temperature | Review the temperature variance in the mold throughout the

curing stage. |

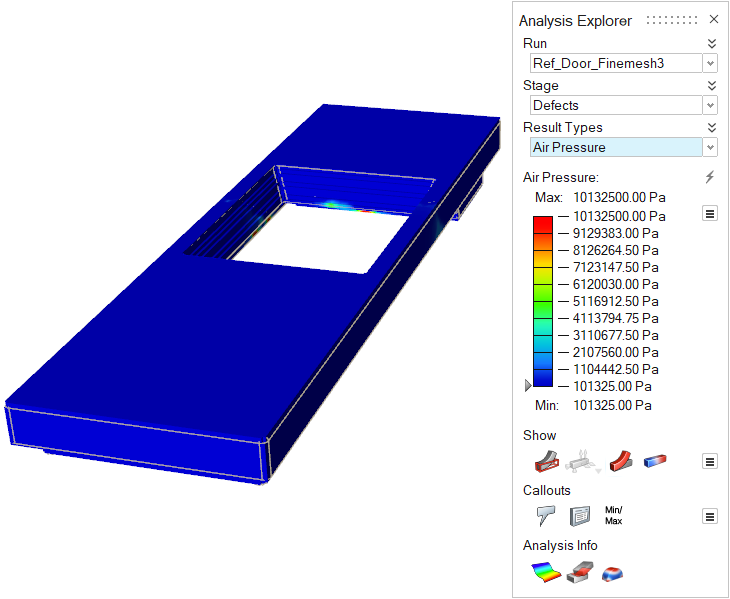

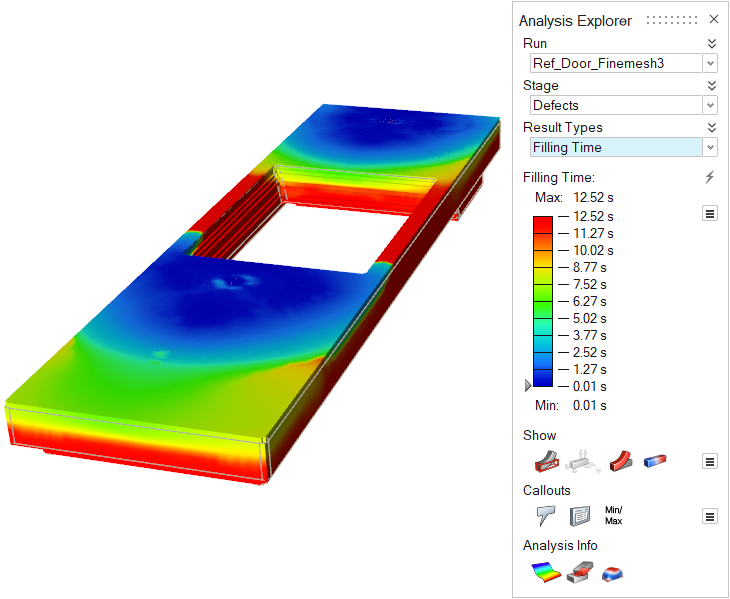

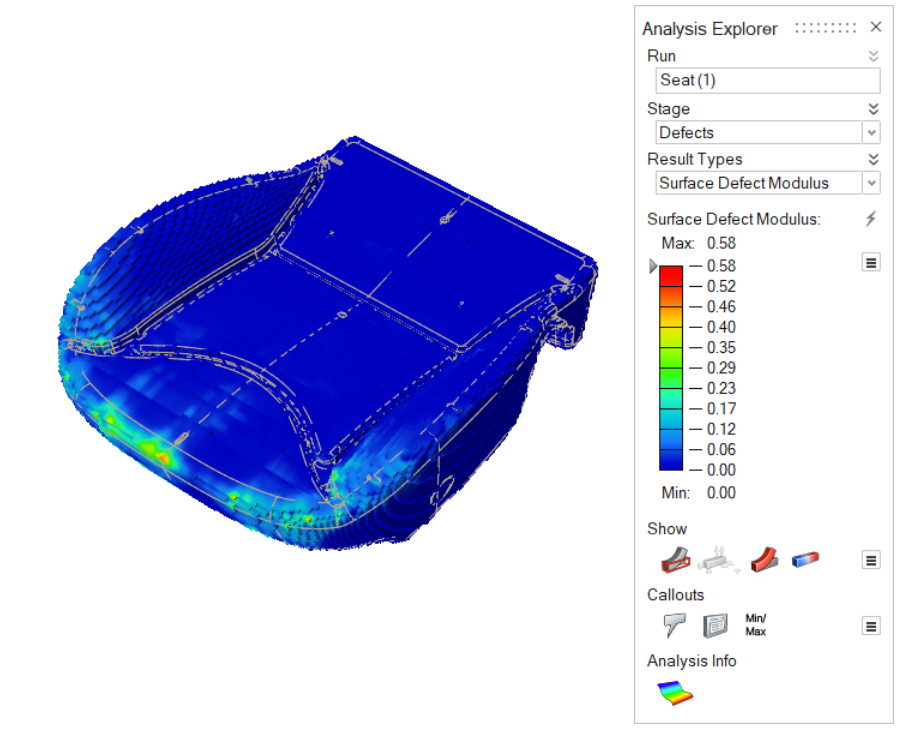

Defects Results

Review a range of defects that can occur at the end of the foaming process. Result types for this stage include: Air Pressure, Filling Time, Surface Defect Modulus, Shrinkage Defect Modulus, Weld Lines, and Weld Lines Movement.

| Option | Description |

|---|---|

| Air Pressure | Display the accumulated air pressure effects on the part at

the end of the simulation. Look for porosity and void

defects. |

| Filling Time | Review the time the material takes to reach different areas of the mold. Consider adjustments to the nozzle paths and tooling.  |

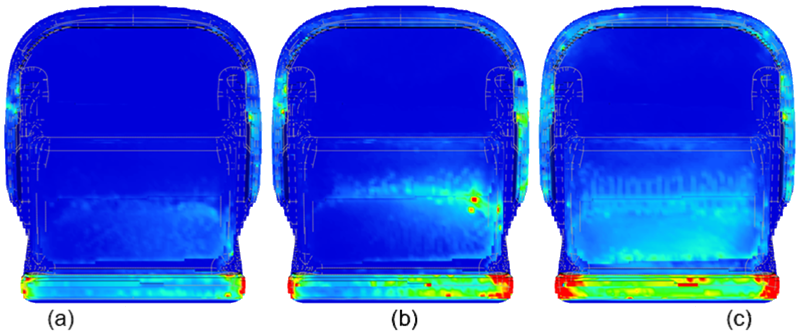

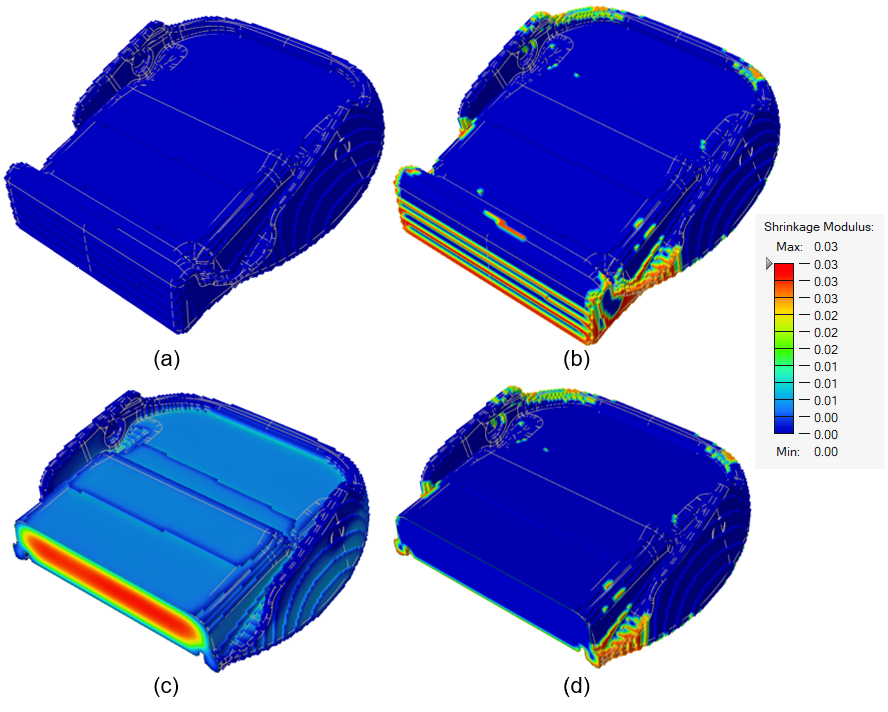

| Surface Defect Modulus | Review the surface of the foam part for coarseness, toughness

and melting that could be due to high mold temperatures, poor

sealing, undried demolding spray, or contaminants. Consider

controlling the mold temperature or modifying the sealing

process. These surface defects can occur when a highly viscous

foam flows through the mold. The Surface Defect Modulus is

dimensionless, and the result is displayed only on the

surface between the part and mold. The following example,

where (a) is 20℃, (b) is 40℃, and (c) is 60℃, shows a defect

area that increases as the mold temperature increases.  |

| Shrinkage Defect Modulus | To produce results that predict the Shrinkage Defect Modulus,

you must select Time as an ending

condition when defining the Process Parameters for your

analysis. A shrinkage defect can occur if the polyurethane

foam is too soft during the molding process or after

demolding. Shrinkage can occur due to over-packing, slow

gelling, and low index. Note that the shrinkage defect model

is appropriate for flexible, polyurethane foam only, not

rigid polyurethane foam.  The following examples show model results where (a) the mold is 40℃, (b) the mold is 20℃, (c) the temperature is shown through the cross-section of the part, and (d) the mold is 20℃ and the shrinkage modulus is shown. No shrinkage occurs when

the mold temperature is 40℃ (a). However, when the mold

temperature dips to 20℃, shrinkage occurs as shown in (b).

Looking at the cross-section (c), shrinkage occurs mainly on

the outer surface of the part because the surface

temperature is lower than the core temperature.  |

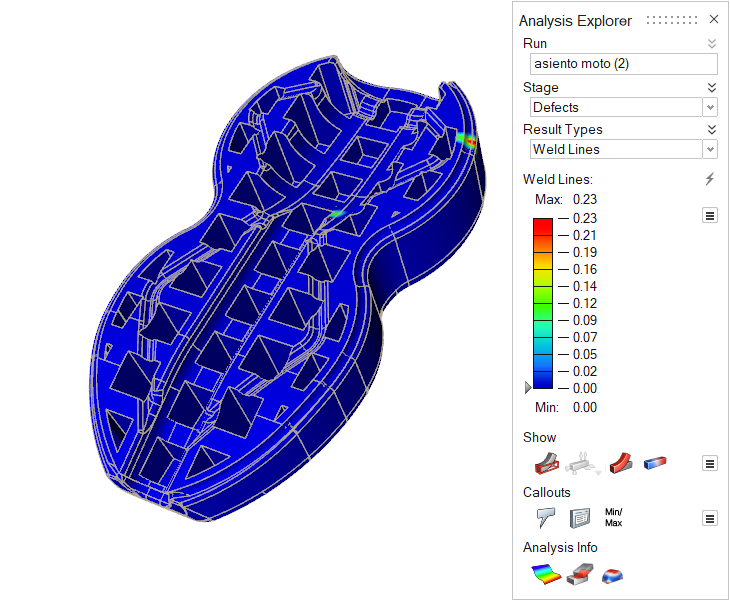

| Weld Lines | Weld lines occur when two separate fluid streams recombine as

a result of multiple nozzles or the shape of the part. Material

does not bond perfectly along weld lines, which can cause

cosmetic imperfections and structural weakness. The Weld Lines

result shows the initial position of weld lines in the

part. |

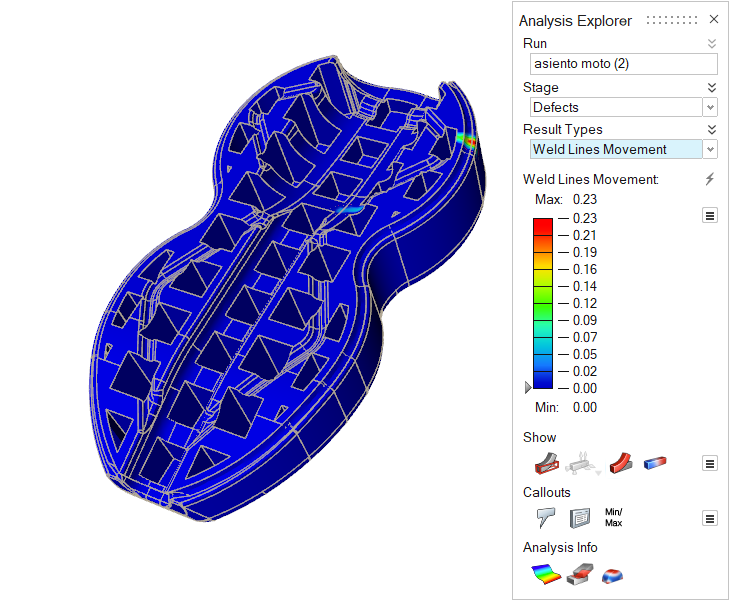

| Weld Lines Movement | Weld lines can shift position as the foam expands. The Weld

Lines Movement result shows the final position of weld lines in

the part. |