Run Analysis

Define parameters and execute an analysis to understand filling, packing, cooling or warpage events during molding. Generate results for individual or combined events.

Complete the model setup before running an analysis.

Note: Analysis results are saved

in the folder specified in your Preferences settings under Molding >

Analysis > Run Options.

-

Click Run Analysis on the Analyze icon..

-

Define the parameters for the analysis.

Tab Option Description Stages

Name Type the name of the run. By default, the name of the model is used. Auto Mesh Enable this option to allow Inspire Mold to automatically determine the optimal mesh size for the analysis. Note: If you enable Auto Mesh, Average thickness and Element Size will be disabled.Element size Enter the average element size for the part cavity. The software creates the mesh based on this value. Filling Select to examine the flow pattern, temperature, and pressures associated with the material entering into the mold.

Packing Select to calculate the pressure necessary during solidification to compensate for contraction due to temperature. Cooling Select to view cooling results in which solidification starts with a totally full mold and ends at a specified temperature or time. Warpage Select to examine evidence of warpage. Warpage can occur when a material shrinks non-uniformly due to high cooling rates, mold restraint, or temperature differences that create internal stresses. Note: You must select the Packing option to make Cooling available, and you must select Cooling to make Warpage available.Select Part Click this button, then select a part in a multi-cavity mold for warpage analysis. Note:- This control is only available when your model has at least two different parts in a multi-cavity mold.

- Warpage results will be calculated for the selected part only.

- Other results will be calculated for all parts.

Configuration

Filling, Packing, Cooling HTC Enter the Heat Transfer Coefficient. W/m2K for each stage of the process. Room temperature Enter the ambient temperature of the work environment Virtual mold temperature Set the desired starting temperature for the mold. -

Click Run.

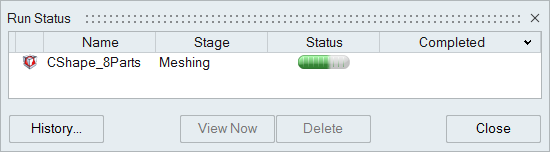

The run status is displayed.