OS-V: 0534 Laminated Shell Strength Analysis Thermal Load 1

This problem analyzes the strength of laminated composite shells when subjected to a uniform constant temperature.

When plies in a laminate have different orientation, the expansion is not identical. The net expansion of the laminates is determined from the compatibility of all the plies. Therefore, this benchmark addresses the failure indices under uniform temperature loading. The model and boundary conditions are described by Hopkins (2005). The resulting ply failure indices and reserve factors are compared against analytical solutions from classical lamination theory (CLT). The results show a good correlation between OptiStruct and CLT.

Model Files

Benchmark Model

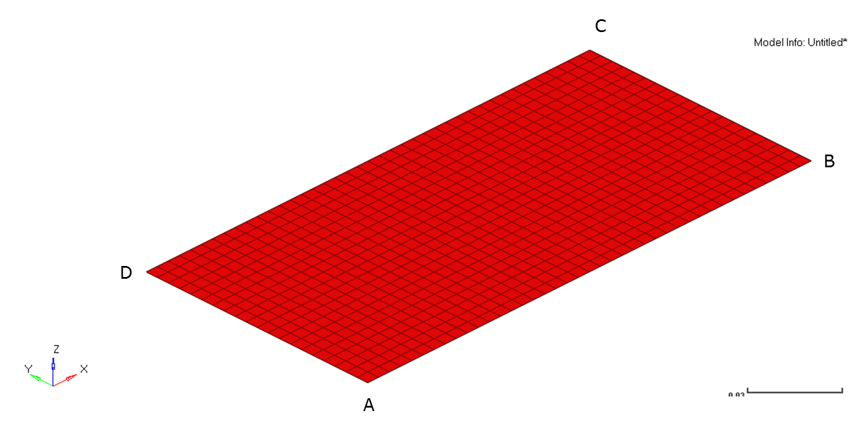

Table 2 lists out all the computed ply failure indices from OptiStruct (OS) based on Tsai-Wu, Hill and Hoffman failure criteria. 800 mesh elements of CQUAD4 element type were used in this study. The model is pinned at point A using a SPC card and a uniform thermal load of 150 °C is applied throughout the domain using a TEMP card.

- Property

- Value

- Longitudinal Young’s Modulus, El (GPa)

- 207.0

- Transverse Young’s Modulus, Et (GPa)

- 7.6

- Longitudinal Shear Modulus, Glt (GPa)

- 5.0

- Major Poisson’s ratio, 12

- 0.3

- Longitudinal Tensile Strength, lt (MPa)

- 500.0

- Longitudinal Compressive Strength, lc (MPa)

- 350.0

- Transverse Tensile Strength, tt (MPa)

- 5.0

- Transverse Compressive Strength, tc (MPa)

- 75.0

- In-plane shear strength, lt (MPa)

- 35.0

- Longitudinal co-efficient of thermal expansion, l (per 0 °C)

- 0.0

- Transverse co-efficient of thermal expansion, t (per 0 °C)

- 30.0 x 10-6

| Ply | Orientation (°) | Thickness ( m) |

|---|---|---|

| 1 | 90.0 | 0.05 |

| 2 | -45.0 | 0.05 |

| 3 | 45.0 | 0.05 |

| 4 | 0.0 | 0.05 |

- Dimension

- Value

- Length (m)

- 0.2

- Breadth (m)

- 0.1

Results

| Midplane Strains | Theory | OptiStruct Result |

|---|---|---|

| x | -0.698 x 10-3 | -0.698 x 10-4 |

| y | -0.698 x 10-3 | -0.698 x 10-4 |

| xy | -0.1661 x 10-10 | -2.611 x 10-13** |

| ** Represents maximum | ||

| Failure Criteria | Ply 1 | Ply 2 | Ply 3 | Ply 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | |

| Tsai-Wu | 5.875 | 5.875 | 6.7875 | 6.788 | 6.7875 | 6.788 | 5.875 | 5.875 |

| Hill | 22.073 | 22.07 | 26.104 | 26.1 | 26.104 | 26.1 | 22.073 | 22.073 |

| Hoffman | 5.9177 | 5.918 | 6.5938 | 6.594 | 6.5938 | 6.594 | 5.9177 | 5.9177 |

| Reserve Factor | Ply 1 | Ply 2 | Ply 3 | Ply 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | |

| Tsai-Wu | 0.21342 | 0.2134 | 0.19239 | 0.1924 | 0.19239 | 0.1924 | 0.21342 | 0.2134 |

| Hill | 0.21285 | 0.2128 | 0.19573 | 0.1957 | 0.19573 | 0.1957 | 0.21285 | 0.2128 |

| Hoffman | 0.21304 | 0.2130 | 0.19369 | 0.1937 | 0.19369 | 0.1937 | 0.21304 | 0.2130 |

This document addresses the verification of numerical results for the criteria and does not address the merits of a particular criteria. ESDU data sheet (1986), Soden et al. (1998) and ESA PSS-03-1101 (1986) address the details of particular failure criteria.

Reference

NAFEMS R0092 - Benchmarks for membrane and bending analysis of laminated shells. Part 1, Stiffness matrix and thermal characteristics

NAFEMS R0093 - Benchmarks for membrane and bending analysis of laminated shells. Part 2, Strength analysis