OS-V: 0533 Laminated Shell Strength Analysis Mechanical Load 3

This problem demonstrates when the loads applied in OS-V: 0532 are factored by 1.1491, a Hill failure index (FI) and a reserve factor (RF) of unity for ply 1 are obtained.

Examination of the FI and RF for each criterion confirms that only for the Hill criteria is the FI directly related to reserve factor, RF = 1/(FI)0.5. For all other plies, the RF are reduced by a factor of 1.149-1, but the FI is not. The model is subjected to a uniform longitudinal, transverse, shear, bending and torsional load per unit length. The geometry of the model and boundary conditions are described by Hopkins (2005). The resulting ply failure indices, reserve factor and midplane strains are compared against analytical solutions from classical lamination theory (CLT). The results show a good correlation between OptiStruct and CLT.

Model Files

Benchmark Model

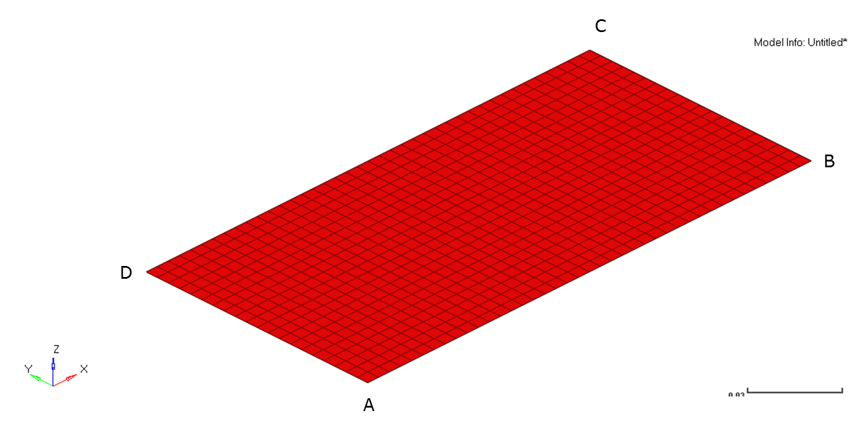

800 mesh elements of CQUAD4 element type were used in this study. The model is fixed at point A using a SPC card; a uniform longitudinal force per unit length (Nx) of 26.573 N/m, uniform transverse force per unit length (Ny) of 28.728 N/m and shear force per unit length (Nxy) of 5.7455 N/m are applied using a FORCE card. Bending moments per unit length (Mx = 0.45964 N and My = -0.8618 N) and torsional load per unit length (Txy = -0.20109 N) are applied along the edges of the laminate using a MOMENT card.

- Property

- Value

- Longitudinal Young’s Modulus, El (GPa)

- 207.0

- Transverse Young’s Modulus, Et (GPa)

- 7.6

- Longitudinal Shear Modulus, Glt (GPa)

- 5.0

- Major Poisson’s ratio, 12

- 0.3

- Longitudinal Tensile Strength, lt (MPa)

- 500.0

- Longitudinal Compressive Strength, lc (MPa)

- 350.0

- Transverse Tensile Strength, tt (MPa)

- 5.0

- Transverse Compressive Strength, tc (MPa)

- 75.0

- In-plane shear strength, lt (MPa)

- 35.0

| Ply | Orientation (°) | Thickness ( m) |

|---|---|---|

| 1 | 90.0 | 0.05 |

| 2 | -45.0 | 0.05 |

| 3 | 45.0 | 0.05 |

| 4 | 0.0 | 0.05 |

- Dimension

- Value

- Length (m)

- 0.2

- Breadth (m)

- 0.1

Results

| Midplane Strains | Theory | OptiStruct Result |

|---|---|---|

| x | -1.9902 x 10-4 | -1.990 x 10-4 |

| y | -6.3794 x 10-4 | -6.4 x 10-4 |

| xy | -4.5136 x 10-4 | -4.51 x 10-4 |

| Failure Criteria | Ply 1 | Ply 2 | Ply 3 | Ply 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | |

| Tsai-Wu | -2.12900 | -2.127 | -2.76890 | -2.77 | -2.13250 | -2.133 | -1.13540 | -1.134 |

| Hill | 1.00000 | 1.00000 | 0.29949 | 0.29950 | 0.08470 | 0.08470 | 0.64777 | 0.64780 |

| Hoffman | -2.56460 | -2.56500 | -2.51860 | -2.51900 | -1.99770 | -1.99800 | -1.36110 | -1.36100 |

| Reserve Factor | Ply 1 | Ply 2 | Ply 3 | Ply 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | Theory | OptiStruct Result | |

| Tsai-Wu | 1.6123 | 1.612 | 3.5651 | 3.568 | 6.3911 | 6.402 | 2.2331 | 2.232 |

| Hill | 0.99998 | 1.000 | 1.8273 | 1.827 | 3.436 | 3.436 | 1.2425 | 1.242 |

| Hoffman | 1.7718 | 1.772 | 2.983 | 2.983 | 4.9355 | 4.933 | 2.6439 | 2.644 |

This document addresses the verification of numerical results for the criteria and does not address the merits of a particular criteria. ESDU data sheet (1986), Soden et al. (1998) and ESA PSS-03-1101 (1986) address the details of particular failure criteria.

Reference

NAFEMS R0092 - Benchmarks for membrane and bending analysis of laminated shells. Part 1, Stiffness matrix and thermal characteristics

NAFEMS R0093 - Benchmarks for membrane and bending analysis of laminated shells. Part 2, Strength analysis