OS-V: 1200 Bar Impact

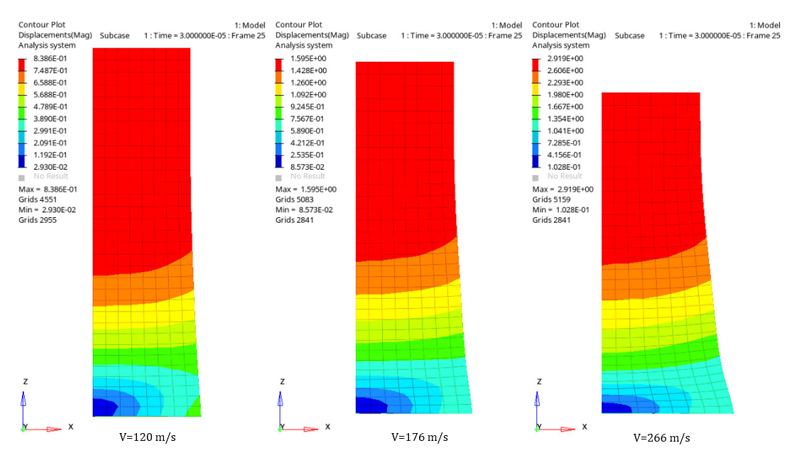

Taylor TestAn elastic-plastic cylindrical bar impacts a rigid planar target with a high velocity (120-266 m/s). Verify the deformation results with the real test results.

Cylindrical bar: length L = 16mm, radius R = 4mm

Model Files

Benchmark Model

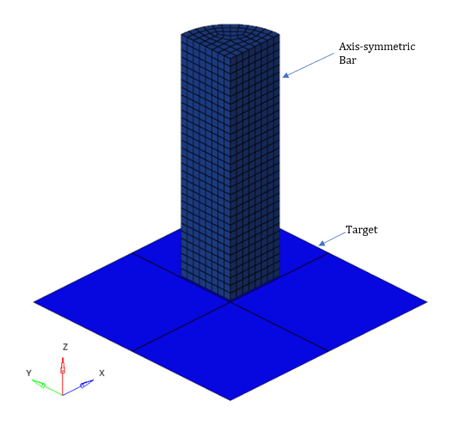

The finite element model, as shown in Figure 1 is meshed with first order CHEXA elements (32 elements along its length and 8 elements along its radius). The bar to target contact is frictionless. The appropriate boundary conditions are applied on the symmetry planes of the quarter model. The cylindrical bar is imparted 3 different velocities of 120.170 and 266 m/s.

Material

- Bar (Elastic-Plastic Stainless Steel) Material Properties

- Young's modulus

- 2.10E+05 N/mm2

- Poisson's ratio

- 0.3

- Density

- 7.85E-09 ton/mm3

- Johnson & Cook Plasticity Parameters

- A

- 350

- B

- 1000

- n

- 0.65

- C

- 0.07

- m

- 1

Results

| Impact Velocity | Length/Radius | Reference Value | OptiStruct Results | |

|---|---|---|---|---|

| Absolute Value | Error % | |||

| 120 m/s | Length | 15.3 | 15.1 | -1.30 |

| Forward Radius | - | 4.433 | - | |

| Mid-Length Radius | - | 4.050 | - | |

| 176 m/s | Length | 14.6 | 14.320 | -1.90 |

| Forward Radius | 4.8 | 4.753 | -1.04 | |

| Mid-Length Radius | 4.1 | 4.128 | +0.68 | |

| 266 m/s | Length | 13.3 | 12.980 | -2.40 |

| Forward Radius | 5.5 | 5.362 | -2.50 | |

| Mid-Length Radius | 4.2 | 4.335 | +3.21 | |

Reference

Calleja P., Terras C., Dormeval R., Ansarf J.-P. (CEA): “Taylor's test on aluminum, copper and stainless steel”, Physics Journal, colloquium C5, supplement to no. 8, Vol. 46, August 1985, pp. C5-91 to C5-99