Tutorial: Adding a Resin Material

Tutorial Level: Beginner Add a new Resin material to the Material Database.

Polymeric resins are broadly classified into thermoplastic and thermoset resins. A typical RTM process uses thermoset resin which requires curing of the resin after the infusion process. Inspire RTM support resin material models that can be used for thermoset resins and to some extent thermoplastic resins.

The complete list of data used is:

- Density

)

) - Thermal conductivity

- Specsific heat

- Viscosity Model

- None

- Carreau Yasuda

- Temperature dependence

- None (should be used with Newtonian)

- Arrhenius

- WLF

- Curing Kinetics Model

- None

- Generalized curing kinetics model

- Constant Rate curing kinetics model

Carreau—Yasuda Model

![]()

Infinite shear viscosity

Infinite shear viscosity  )

)  Zero shear viscosity

Zero shear viscosity )

) Carreau Constant (use 1)

Carreau Constant (use 1) Time Constant

Time Constant  )

) Power-law index

Power-law index  )

) Transition parameter

Transition parameter  )

)

Temperature Dependence

Arrhenius Function

![]()

Temperature dependence

Temperature dependence

Activation energy

Activation energy

Universal gas constant

Universal gas constant

WLF Function

![]()

Temperature dependence

Temperature dependence

WLF Constant 1

WLF Constant 1

WLF Constant 2

WLF Constant 2

Reference Temperature

Reference Temperature

Curing Kinetics Model

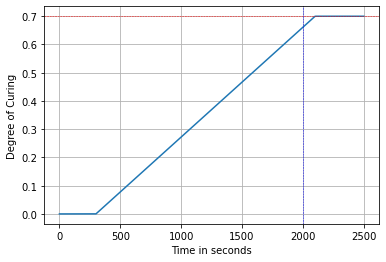

Constant Rate Model

![]()

Gelation cure

Gelation cure

Gelation time

Gelation time

Generalized Curing Kinetics Model

![]()

Nth order coefficient

Nth order coefficient

Nth order exponent

Nth order exponent

Autocatalytic coefficient

Autocatalytic coefficient

Autocatalytic exponent 1

Autocatalytic exponent 1

Autocatalytic exponent 2

Autocatalytic exponent 2

Gelation Model

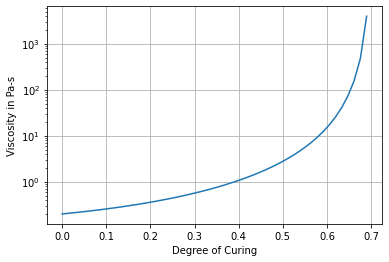

This is related to curing kinetics and describes how the viscosity increases wi

![]()

Gelation cure

Gelation cure

Gelation viscosity constant C1

Gelation viscosity constant C1

Gelation viscosity constant C2

Gelation viscosity constant C2

Latent Heat

![]()

Latent heat of curing

Latent heat of curing

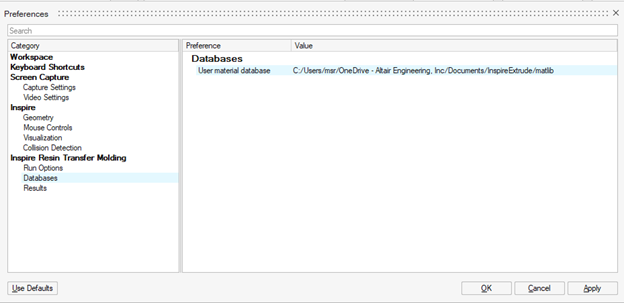

Specify User Materials Folder

- On the File menu, click the Preferences button.

-

Select Databases under Inspire Resin Transfer

Molding, then enter a location for the user materials to be

created.

Note: When creating new materials, make sure you are in the User Materials database specified here. You may not have permission to create/edit materials in the system folder.Typically, you will be able to use this across multiple versions.

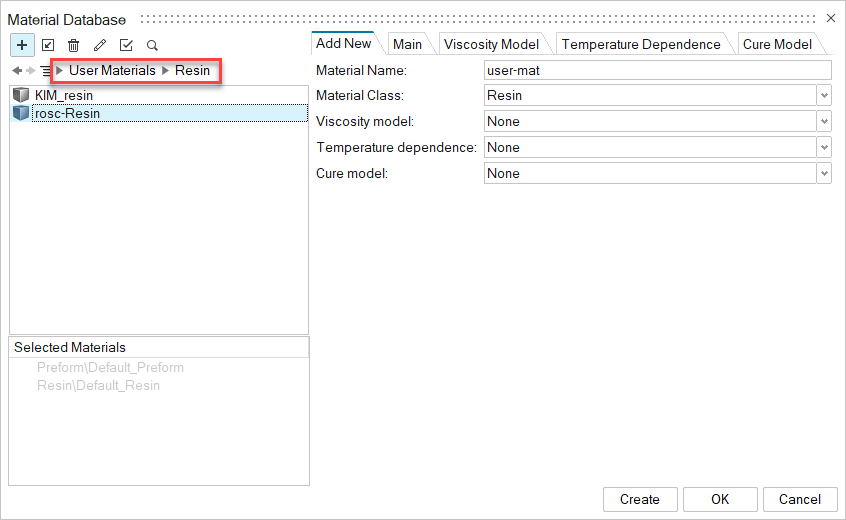

Create Resin Material Entry

-

From the Resin Transfer Molding ribbon, click the

Materials tool.

-

Ensure that you are in the User Materials section and

select the Resin folder then click

to add a new material

.

to add a new material

.

-

Enter the following data to create the new material

- Density = 1160 kg/m3

- Viscosity = 0.20 Pa-s

- Compressibility = 1.0e-09

- (Thermal) Conductivity = 0.170

- Specific heat = 1100

- Cure model = Constant Curing Rate Model

- Latent = 2100.0 J/kg

- Gelation time = 1800 s

- Gelation Cure = 0.70

- Gelation Viscosity C1 = 1.50

- Gelation Viscosity C2 = 1.20

- Curing initiation time = 300 s (specified at the inlet)

- Click OK to confirm.