What is Inspire Resin Transfer Molding?

Inspire Resin Transfer Molding offers an analysis tool for virtual testing, validation, correction, and optimization of resin transfer molding designs.

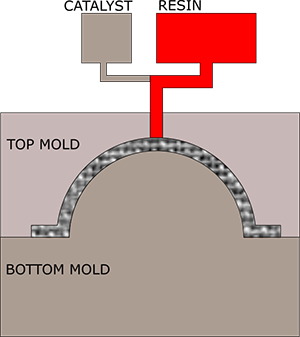

Composite materials are of great importance to the aerospace and auto industry owing to the high strength to weight ratio exhibited by these materials. Resin Transfer Molding (RTM) and its variants such as VARTM are used to manufacture composite parts. In a typical process, a thermoset resin is injected into the mold containing the fibrous preform, and then it is cured to produce the final part. Inspire Resin Transfer Molding (Inspire RTM) is used to simulate this process to detect processing defects and optimize the process.

Description of a Typical RTM Process

- Mold closes.

- Depending on the process type, air may be removed to create a vacuum.

- Resin mixed with a curing agent is infused into the mold.

- Depending on the curing agent, it is activated by time or temperature.

- Curing reaction forms the crosslinking in the thermoset resin and the process is completed. Curing is often an exothermic reaction that releases heat.

- Mold is opened, and the part is taken for further post-processing.

Challenges in Manufacturing Process and Role of Simulation

- How to fill the part completely?

- Without short shots?

- With available pressure?

- Before curing kicks in?

- Avoiding air traps?

- Does the resin race track in the part to the vent?

- How to fill it quickly?

- Filling quickly saves time and improves productivity.

- How does the part cure?

- Does the part warp after the RTM process?

- What is the strength of the part after the process is completed?

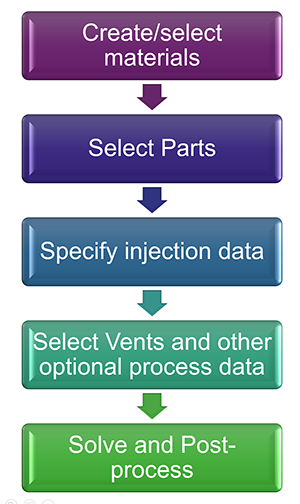

Overview of Simulation Process