SPH Flow

To prepare a nanoFluidX model, a SPH Flow solution (Smoothed Particle Hydrodynamics) must be defined in SimLab and dedicated to nanoFluidX.

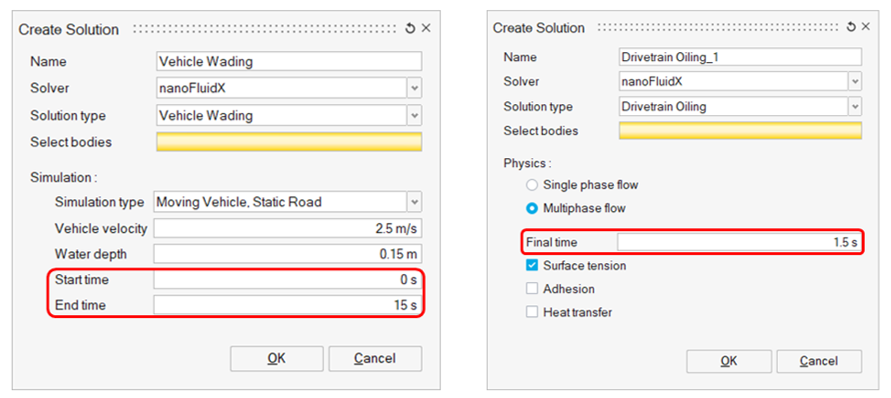

There are three solution types available, Drivetrain Oiling, Vehicle Wading, and Water Management. The Create Solution settings are also detailed.

In SimLab, go to .

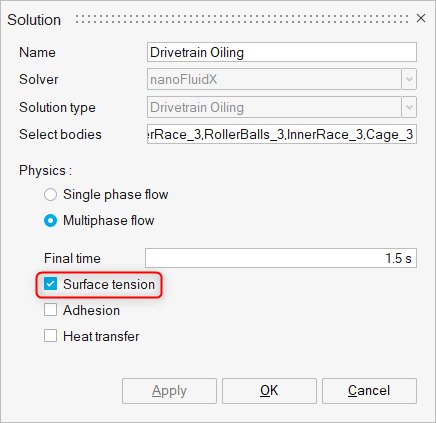

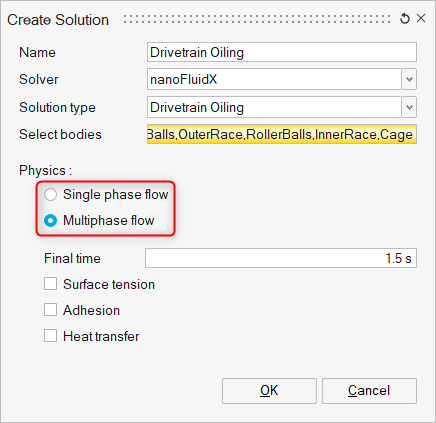

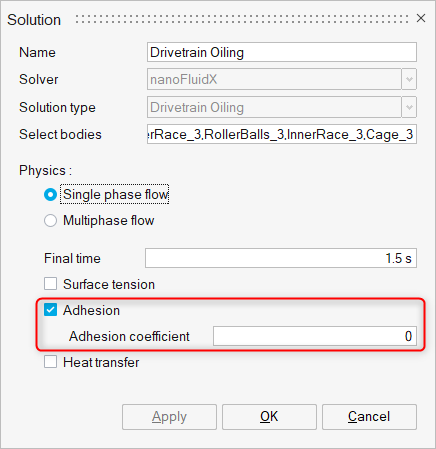

Drivetrain Oiling

In this solution, physics can be solved based on single-phase or multiphase flow.

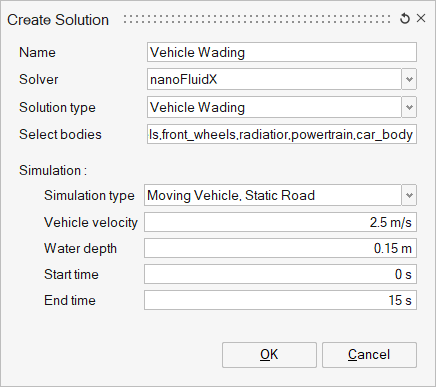

Vehicle Wading

This solution is designed for simulation vehicle wading through deep water. Two approaches are available for simulation type, Moving Vehicle/Static Road and Static Vehicle/Moving Road. These simulations are characterized by complex geometry interacting with a free surface fluid. Vehicle wading simulations in nanoFluidX are always single-phase simulations.

- Moving Vehicle [Moving Vehicle, Static Road]

- This approach mimics a real-world condition. A water channel is defined, and the vehicle drives through it. This approach is more realistic and captures the dynamic fluid behavior during water entry and exit. It is recommended for comparing physical tests. However, it is the more computationally expensive approach.

- Moving Vehicle [Moving Vehicle, Static Road]

- This approach is simpler and uses a configuration like a wind tunnel. The vehicle remains static, but the road and wheels are assigned boundary conditions that mimic the correct vehicle speed. Water approaches the vehicle from an inlet at the front of the channel. This approach is less computationally expensive than the moving vehicle simulation, but it is not possible to capture the fluid behavior during water entry and exit.

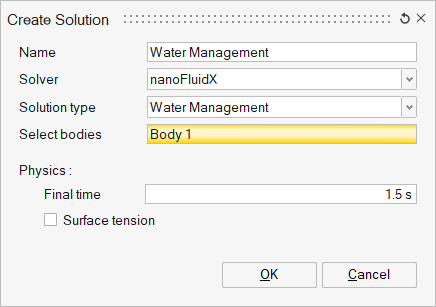

Water Management

Select Bodies

Select the bodies to be included in the simulation. Only the bodies selected will be used for the simulation, even though there are more bodies in the SimLab database. Currently CAD bodies are not supported in the solution, only tessellated/meshed FEM bodies are permitted.

Physics

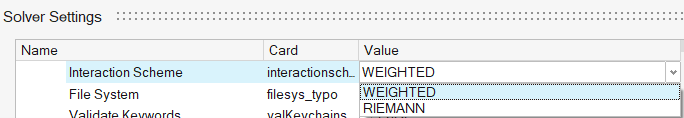

- Interaction Scheme

- In Solver Settings you can choose whether to use Riemann or Weighted interaction schemes (interactionscheme). Weighted is the default choice and is capable of handling violent and chaotic multiphase flows. Riemann results in smoother pressure gradients and less breakup of sprays and jets but will experience local instabilities with more violent flows.

- Surface Tension

- Choose if surface tension is active (surften_model) and which model to use. By default, surface tension is disabled, since it adds computational cost.

- Adhesion

- Specifies whether the Akinci wall adhesion model (adhesion_model) is

active. This is used in conjunction with surface tension to define how

the fluid interacts with the wall and the contact angle of a fluid

droplet on the wall.

Figure 6.

Important: Adhesion Coefficient (adhesionCoeff) must also be set in Material (phase) parameters when using the adhesion model. - Heat Transfer

- Activates energy_transport so that the energy equation is solved by

nanoFluidX for conduction and convection

heat transfer.Important: When Heat Transfer is used, initial temperature (temp_0), evolve temperature flag (evolve_temp), specific heat capacity of the material (heat_cap) and heat conduction coefficient of the material (heat_cond) should be set in Material (phase) parameters. Heat Transfer and Flux output should also be requested in Results Request.

Simulation

dx sets the particle spacing to be used for the simulation. For guidance on selecting dx, see Particle Resolution - how to decide dx.

Start time (t_begin) is 0 by default. This only needs to be adjusted when running a restart simulation.

End time (t_end) defines the finishing time of the simulation.