Screw2

Analyze the board to prevent damage.

More detailed information:

- Screw Definition

- Component Group

- Component Group: Select a component group for screw assignment.

- Measure Base: Select a measurement base.

- Via Size: Recognize the specified via as a screw.

- Pad Shape: Set the clearance measurement based on the pad shape of the screw.

- Hole Shape: Set the clearance measurement based on the hole shape of the screw.

- Hole Center: Set the clearance measurement based on the hole center of the screw.

- Board Figure: Recognize the board figure as a screw.

- Padstack: Set the padstack using a string filter. Use this

when the screw was designed with the board figure pad.

- Import(.txt): Apply Filter Type based on the

characters entered in the .txt file.

- Apply as a prefix when (|F|) ABC is entered in the .txt file.

- Apply as a mid-string when ABC is entered in the .txt file.

- Apply as a suffix when ABC(|P|) is entered in the .txt file.

- Export(.txt): Export the characters registered in the String Item in .txt file format.

- Import(.txt): Apply Filter Type based on the

characters entered in the .txt file.

-

- Pad Shape: Set the clearance measurement based on the pad shape of the screw.

- Hole Shape: Set the clearance measurement based on the hole shape of the screw.

- Hole Center: Set the clearance measurement based on the hole center of the screw.

- Figure Diameter: Recognize an object designed with Figure

hole using the hole size as the screw.

- Hole Shape: Set the clearance measurement based on the hole shape of the screw.

- Hole Center: Set the clearance measurement based on the hole center of the screw.

- Padstack: Set the padstack using a string filter. Use this

when the screw was designed with the board figure pad.

- Component Group

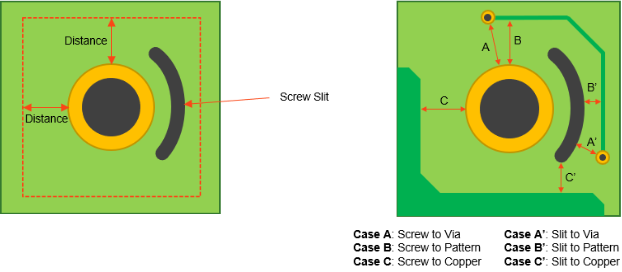

- Silt Definition

- Distance to slit area from a screw measure base: Define an area to find a slit hole.

- Silt Layer: Select a layer that is drawn in the slit hole.

Figure 1.

- Checking

- Recognize Selected Component’s Placed Side as Top: Recognize the component placed layer as the top layer.

- Clearance to Component

- Item: Specify the item name.

- Component Group: Select the component group for analysis.

- Measure Base: Select a measurement base.

- Screw: Select a screw for analysis.

- Screw Measure Base: Select a measurement base for the screw.

- Top Clearance: Set the clearance between the screws and components placed on the top layer.

- Bottom Clearance: Set the clearance between the screws and components placed on the top layer.

- Remainder: Set the clearance for the remainder.

- Item: Specify the item name.

- Component Measure Base: Select a measurement base.

- Screw: Select a screw for analysis.

- Screw Measure Base: Select a measurement base for the screw.

- Top Clearance: Set the clearance for the analysis between the screws and components placed on the top layer.

- Bottom Clearance: Set the clearance for the analysis between the screws and components placed on the top layer.

- Except for SMD Pins, not having Metal-Mask: Exclude the SMD component’s pin that does not have metal mask data.

- Clearance to Via: Set the clearance between the screw and via for

the top, bottom, and inner layer.

- Item: Specify the item name.

- Screw: Select a screw for analysis.

- Screw Measure Base: Select a measurement base for the screw.

- Target: Select a target object for analysis among Screw, Slit, and Screw+Slit.

- Top Clearance: Set the clearance between the screws and vias on the top layer.

- Inner Clearance: Set the clearance between the screws and vias on the inner layer.

- Bottom Clearance: Set the clearance between the screws and vias on the bottom layer.

- Clearance to Pattern: Set the clearance between the screw and

pattern for the top, bottom, and inner layer.

- Item: Specify the item name.

- Screw: Select a screw for analysis.

- Screw Measure Base: Select a measurement base for the screw.

- Target: Select a target object for analysis among Screw, Slit, and Screw+Slit.

- Top Clearance: Set the clearance between the screws and route patterns on the top layer

- Inner Clearance: Set the clearance between the screws and route patterns on the inner layer.

- Bottom Clearance: Set the clearance between the screws and route patterns on the bottom layer.

- Except Net Segments under Pad Area: Exclude a nets existence in the component pad area during analysis.

- Except Pattern Overlapped with Copper: Exclude pattern overlapped with copper.

- Except Pattern Overlapped with Component Group: Exclude

pattern overlapped with Component specific area.

- Measure base: Select a measurement base.

- Clearance to Copper: Set the clearance between the screw and

copper-pour for the top, bottom, and inner layer.

- Item: Specify the item name.

- Screw: Select a screw for analysis.

- Screw Measure Base: Select a measurement base for the screw.

- Target: Select a target object for analysis among Screw, Slit, and Screw+Slit.

- Top Clearance: Set the clearance between the screws and copper polygons on the top layer.

- Inner Clearance: Set the clearance between the screws and copper polygons on the inner layer.

- Bottom Clearance: Set the clearance between the screws and copper polygons on the bottom layer.

- Exclude Ground Net: Exclude the ground net from analysis by using the string filter.

- Exclude Same Net: Exclude nets connected to the screw from the analysis.

- Slit existence check: Check the existence of slits around the screws that are inspected.